India ITME (International Textile Machinery Exhibition) 2022 is a leading trade fair for the textile industry, showcasing the latest innovations and technologies in the field. This year, the event featured a range of new products and technologies in the sectors of spinning, weaving, processing, and digital printing.

In the spinning sector, several companies displayed innovative machines that can produce high-quality yarn at high speeds and with improved efficiency. Meera Industries has developed a Twine Twister that is capable of completing S & Z twists in a single step. The ability to produce S & Z twists in one machine can significantly improve efficiency and productivity in the production process. Similarly, their other machine, that is capable of Twisting, Prying, and Reverse Twisting in a single step is also a valuable innovation. By reducing the number of steps required to produce twisted yarn, the TPRT machine can help to streamline the production process and save time and resources.

ELGI Electrics launched their new cubical yarn conditioning machine, with capacity of 360Kg to 3000Kg per batch, you can also link the machine with automatic cone transport system.

In the weaving sector, companies showcased new types of looms that can produce complex and intricate fabrics with greater precision and speed. These looms use advanced technologies such as lasers, robotics, and computer-aided design (CAD) to produce high-quality fabrics in a shorter time. Some of the new looms also have the ability to produce fabrics with multiple colours and patterns, allowing for greater design flexibility.

Rabatex has developed an Advanced Sample Warping Machine with advanced features such as 18 axis control and the ability to produce 16 color patterns. The machine’s capacity to produce warp lengths of up to 700 meters is also noteworthy, as it allows for the production of longer lengths of warp yarn, which is essential for many textile applications.

Prashant Industries has developed a new direct warper for cotton and filament yarns with a high capacity of 1200 meters per minute. The use of Industry 4.0 automation in the machine allows for greater efficiency and precision in the warping process, resulting in a more consistent and high-quality product.

The processing sector saw the introduction of new machines that can improve the quality and efficiency of fabric finishing processes. TexFab has displayed a Loops steamer with new features such as the ability to fix the colour of reactive prints. This added feature can improve the quality and durability of the finished fabric, as it helps to prevent fading or bleeding of the colours during washing or other processing steps. The fact that TexFab received an award in the finishing sector at India ITME 2022 further demonstrates the company’s commitment to innovation and the development of high-quality products.

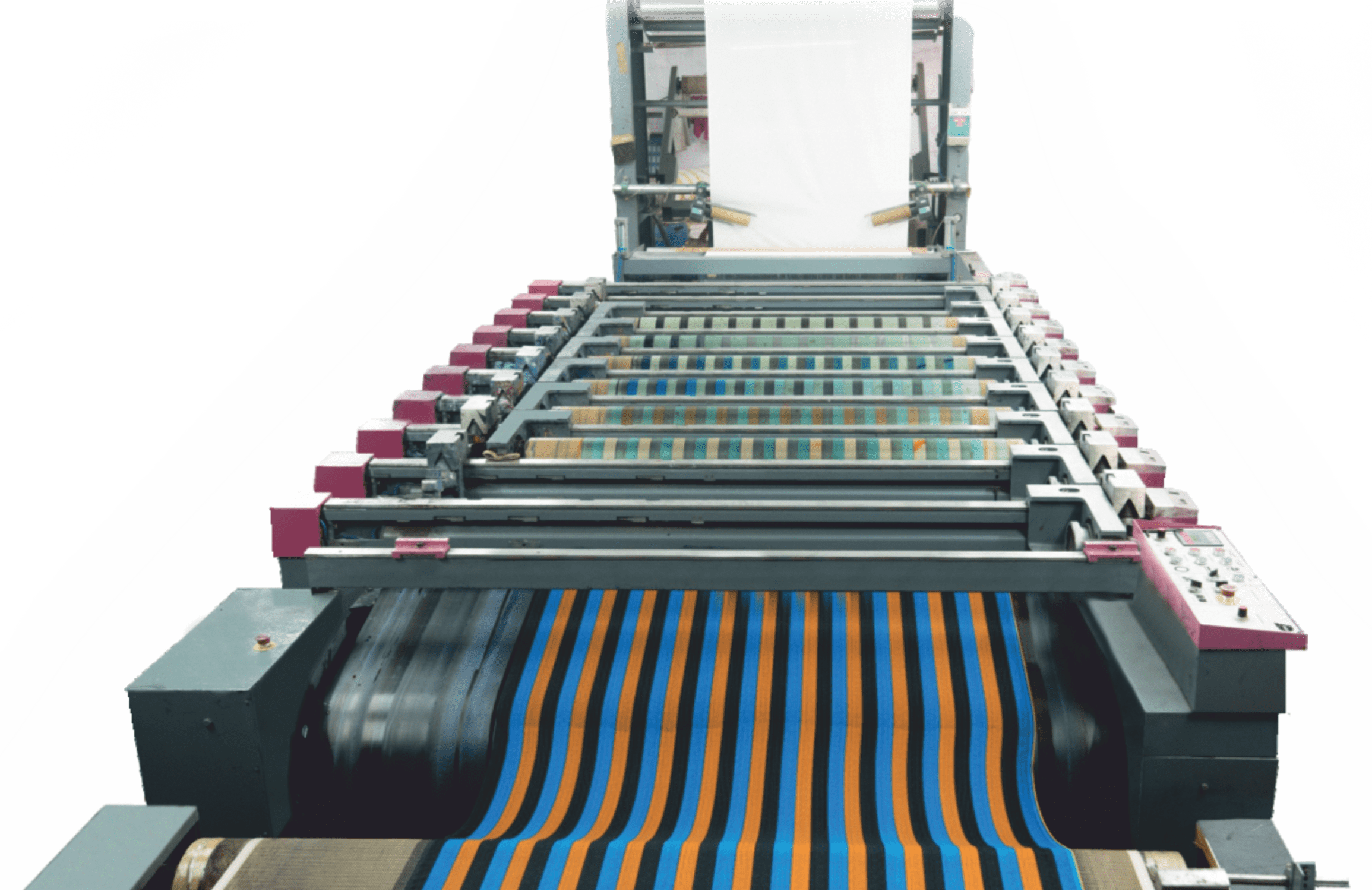

The Embee Group has developed printing machines, such as the ACUMEN and SIGNATURE, with advanced features such as individual drive heads and multi repeat printing heads with a precision of 0.1mm. These features allow for greater control and accuracy in the printing process, resulting in a more consistent and high-quality product. The ability of the machines to be used for both wider and narrow width fabrics adds value, as it allows for greater versatility and the production of a wider range of fabrics.

The digital printing sector also saw a number of new innovations at India ITME 2022. Companies displayed new printers that can produce high-quality prints with a wide range of colours and patterns, using eco-friendly inks and processes. Some of the new printers also have the ability to print on a variety of fabrics and materials, including natural and synthetic fibres.

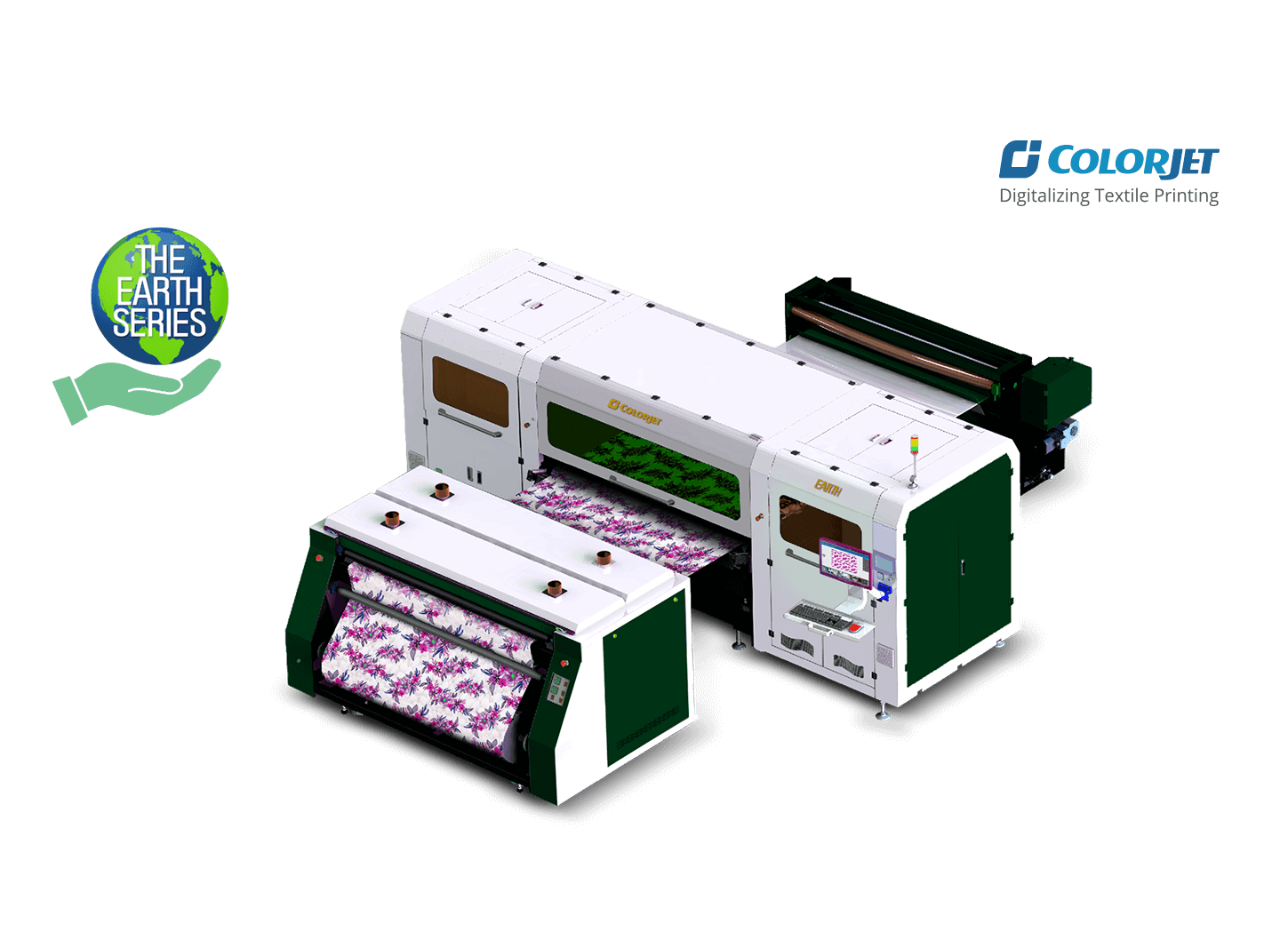

CLORJET Group launched their sustainable Pigment printing solution –EARTH SERIES. ColorJet EARTH Series is an advanced sustainable printing solution in the Digital textile printing segment. This new process does not require additional equipment for pre and post treatment. By eliminating pre-& post treatment, this has led to huge saving of water and energy, and provides a competitive edge in the sustainable direct-to-fabric printing category.

Tanya Enterprises displayed their digital printers, the printers have capacity to print at 15 sq. m per hour using nine different CMYK colours. The printers can also print using fluorescent colours. Their DTF (Direct to Fabric) printers comes with three heads, CMYK, white and neon. The printers can print on variety of fabrics from Polyester, Cotton and Denims.

Overall, the innovations showcased at India ITME 2022 demonstrate the continued growth and development of the textile industry in India. With the adoption of new technologies and processes, the industry is poised to continue producing high-quality fabrics and garments that meet the needs and expectations of consumers.