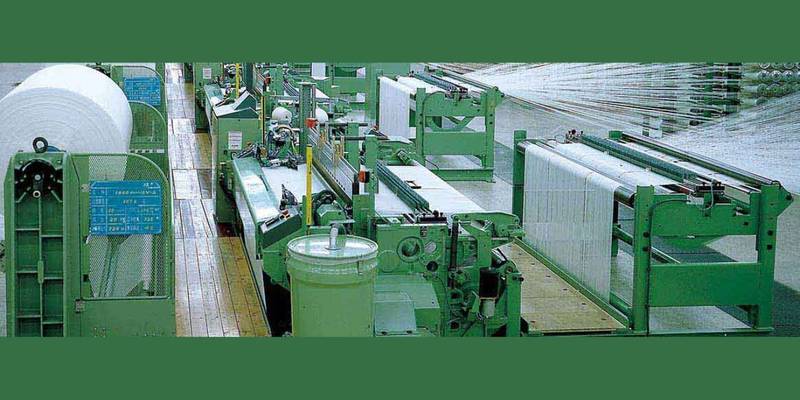

Textile machines are known for their intensive and continuous operations, which expose them to high levels of wear and tear. Therefore, it is essential to ensure that their wear parts are strong and durable enough to withstand the pressure. In this article, we will explore the importance of hardness in wear parts and list the major wear-resistant parts used in textile machines.

The Importance of Hardness in Wear Parts

Wear parts in textile machines are subject to a variety of stresses such as abrasion, impact, and friction. Therefore, they need to be hard enough to withstand these stresses and maintain their shape and functionality. High hardness also helps to resist deformation and prevents the occurrence of cracks and other forms of damage.

To achieve high hardness, several methods can be used, including induction hardening, carburizing quenching, furnace quenching, and others. Induction hardening, in particular, is widely used in the production of wear parts. This process involves heating the surface of the part using high-frequency induction heating and then quenching it with a coolant. This method results in a hard and wear-resistant surface layer while maintaining a soft and flexible core.

List of Major Wear-Resistant Parts

The following are the major wear-resistant parts used in textile machines:

- Various Shafts: Shafts are a critical component in textile machines as they are responsible for transmitting power and motion to other parts of the machine. They are subject to high levels of friction and wear, and as such, require high hardness. Induction hardening is a common method used to harden shafts.

- Bearings: Bearings are essential in reducing friction and ensuring the smooth operation of the machine. They are exposed to a range of stresses, such as radial and axial loads, vibration, and shock, which can cause wear and damage. Bearings need to be made of high-strength materials and hardened to withstand these stresses.

- Gears: Gears are responsible for transmitting power and motion to other parts of the machine. They are exposed to high levels of wear and tear due to continuous engagement and disengagement. To ensure their durability and longevity, they need to be made of high-strength materials and hardened to resist wear.

- Blades: Blades are used in various textile machines for cutting, shearing, and other purposes. They are subject to high levels of wear and deformation, and as such, need to be made of high-strength materials and hardened to maintain their shape and functionality.

In conclusion, wear parts are crucial to the efficient and long-lasting operation of textile machines. The use of high-strength materials and hardness-inducing processes such as induction hardening can help ensure that these parts withstand the stresses and pressures of continuous use. By understanding the importance of wear parts and their hardening processes, textile machine manufacturers can produce durable and reliable machines that meet the demands of the industry.