INTRODUCTION

Coffee is one of the most popular and consumed beverages in the world, which leads to a high contents of solid residue known as spent coffee grounds (SCG).

Spent coffee grounds are the waste product from brewing coffee, in the final stages of coffee preparation. It is estimated daily 3.5 billion cups equates to around 33 million pounds of coffee grounds used and discarded every day. There are a growing number of businesses and individuals finding unique ways to repurpose coffee grounds (in ink for example) so that it’s not waste, but instead, a potential new resource. One of those ways is in textiles.

Singtex CEO Jason Chen worked with Scientists and researchers to develop a yarn that was partially made from coffee grounds, resulting in the launch of a line of coffee fabric called S.Cafe. Coffee ground waste is now being used to make fibers then yarn and ultimately fabric. It has many functional properties , and creative applications, it is eco friendly as well. Using coffee grounds to do this is marketed as a greener alternative, both because it makes use of a resource that would otherwise go to waste, and it provides an alternative to using more conventional chemicals to achieve a similar performance capability.

PROCESSING OF COFFEE FIBER

Coffee grounds can be transformed into yarn through a temperature of 160°C for carbonization, which is energy efficient in comparison to 600°C for normal yarn.The basic procedure to obtain the green fibre yarn includes mixing the coffee residue into a recycled plastic bottle material and re-polymerising to masterbatch and spinning to a coffee yarn, this is the basic procedure.The raw material is a combination of coffee and recycled polyester; the finished textile quality and appearance are as good as those achieved by using new materials.

Preparation of Material with Coffee Residue and Carbonized Coffee Particles

- Preparation material with coffee residue

The term ‘material with coffee residue’ includes microencapsulated backed coffee residue, microencapsulated coffee essential oil, microencapsulated fragrance organic compound which is extracted from coffee residue. Coffee essential oil could be extracted from the coffee bean. Then backed coffee residue or coffee essential oil was microencapsulated.

- Cleaning or sieving of coffee residue or raw material

The coffee bean waste is rinsed in clean water and then dried, in that case, a ground particle having a size of 20 to 100 micron. Then the ground mixture is sieved. The resultant composition can be sieved into different fine particle sizes between 80 – 100 um.

- Removal of organic contents from material with coffee residue

The sieved mixture treated is with some solvents to remove the organic contents from the mixture. The extraction of fat is carried out in soxhlet type extractor with ethyl ether. After the fatty acid has been removed, the aqueous solution containing water-soluble constituents is evaporated to reduce the pressure and extracted with absolute alcohol for removal of glycerol.

- Preparation of carbonised particles

The mixture from the above 3 steps is collected and carbonised using carbonisation. For example, pyrolysis is the process in which coffee mixture is heated, decomposed and eventually converted into the desired product in the presence of air. Pyrolysis includes carbonisation, charcoal processing, gasification, activated carbon processing. The carbonisation of coffee raw material is done in the presence of chemicals such as zinc chloride, magnesium chloride, calcium chloride or phosphoric acid.

- Mixing of material with carbonised material to form a mixture.

- Blending the mixture with the polyester chip in a weight ratio of 1:9 to produce a masterbatch.

In this process ground particle and polymer chip (such as PP, Nylon or PET) in the weight ratio of 1:9 are blended to prepare masterbatch. Alternatively, 75 percent of carbonised particles and 25 per cent the material with coffee fragrance are blended into polymer chip (such as PP, Nylon or PET) to make masterbatch.

- Drawing of Yarn from masterbatch.

- Making fabric with it.

FUNCTIONS

ODOUR CONTROL

It is the tendency of human body to produce odours. The textile has coffee grounds embedded as a fiber. This sucks up all the odour which the body produces. Thus , the fiber doesn’t let it pass through the fabric and the body is odourless. This odour blocking function will permanently exist.

It is the tendency of human body to produce odours. The textile has coffee grounds embedded as a fiber. This sucks up all the odour which the body produces. Thus , the fiber doesn’t let it pass through the fabric and the body is odourless. This odour blocking function will permanently exist.

FAST DRYING

Perspiration is caused by human body. Textile from coffee ground fibers have a unsmooth surface. This helps in spreading water evenly on the surface of the fabric. Since water is spread out across the surface, it lower the duration of the drying process. Thus, it keeps the wearer dry and comfortable.

Perspiration is caused by human body. Textile from coffee ground fibers have a unsmooth surface. This helps in spreading water evenly on the surface of the fabric. Since water is spread out across the surface, it lower the duration of the drying process. Thus, it keeps the wearer dry and comfortable.

UV RAYS PROTECTION

Many skin ill nesses are caused due to UV rays. So it is very important that the human skin be protected against it. Coffee grounds come with numerous microscopic pores, in the fiber itself. It create a long-lasting natural and chemical free shield for yarn or fiber. The fabric is able to refract the UV rays. Its UPF rating reaches upto 50 plus.

nesses are caused due to UV rays. So it is very important that the human skin be protected against it. Coffee grounds come with numerous microscopic pores, in the fiber itself. It create a long-lasting natural and chemical free shield for yarn or fiber. The fabric is able to refract the UV rays. Its UPF rating reaches upto 50 plus.

APPLICATIONS

Apparel Textile: Coffee fibre can be used in apparel Textile like clothing, it can be used in activewear, T-shirts and even sports bras. As the coffee fibre offers 200 percent faster-drying capacity, it can be used for manufacturing sports cloth. Eco-Friendly fabric can be washed easily without the need of any detergent.

Home furnishings: The coffee ground fibre was used primarily in clothing, but this material can be used as part of the structures in the interior design for coffee shop and home furnishings.

Athletic wear: Roasted coffee has natural deodorising properties so that fabric made from coffee yarn has great application in Athletic wear. Which is designed to soak up the sweat. Apart from this, it is found that coffee fibre is faster drying and serve as UV shield, hence fabric gives a perfect match for athletic wear.

FUNCTIONAL PRODUCTS MADE USING COFFEE GROUND WASTE

ECO SPONGE

Made from 25% coffee bio compound and it can apply to different areas. It is created for the manufacturers who are looking for high-performance alternatives to replace petroleum-based products. Built entirely from recycled plastic bottles and discarded coffee yarns. This is specially for jackets for insulation properties.

- Warmth

Made entirely of recycled fibers, as soft and comfortable as down feathers keeping you warm and toasty. - Wind-resistant

the multilayer insulation makes it hard for wind to penetrate through, even under harsh conditions. - Odor Control

Utilizing coffee yarn , boosts the ability to absorb undesired body odor. - Lightweight & Compressible

Eco sponge is able to achieve great warmth to weight ratio, being extremely lightweight as down feathers and compressible to fit in the most compact area.

COFFEE GROUND X WOOD PULP

Yarns combine with Lyocell filaments creating a soft textile, a fabric made from discarded coffee grounds and biodegradable wood pulp. With the great functions of odor-control, moisture absorption, high tenacity and stability, excellent drape and brilliant luster.

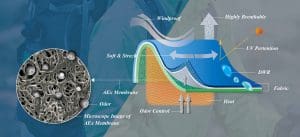

AEx MEMBRANE

A membrane having air technology is kept between two layers of coffee ground fabric to get the additional factor of wind resistance.

By using foam coating technique enable to block 96-98% of wind. The remaining air circulates within the fabric, greatly enhancing moisture vapor transmission, while reducing the risk of heat stress build up.

The body loses heat largely by evaporation and convection. Wind Chill Factor makes us feel colder in winter than the air temperature really is. Reducing wind chill helps keep the body warm and comfortable.

ENVIRONMENTAL MERITS

- Enhance the life cycle of the coffee industry and make the waste more valuable.

- The manufacturing process of coffee fibre involves the use of chemicals which are non-toxic in nature.

- The manufacturing of a new product does not require high temperature for carbonization, so its manufacturing process is more efficient.

- Coffee ground fibre come under the environmentally friendly textile as the fibres are 100 percent biodegradable and do not create an impact on the environment as well.

- Instead of focusing on the end-product test, the blue sign is one standard association which analyses all input in producing products from raw material to the chemical component, to water and energy resources.

- The blue sign is one textile standard association, these blue sign standards analyze all input in producing an article from raw material to the chemical component, to water and energy resources.

- The blue sign standard is dedicated to protecting consumers and reducing the environmental impact by minimizing the waste and emission and reducing resources usage. It designed to solution for reducing the environmental impact.

POTENTIAL AREAS WHERE COFFEE GROUND FIBER CAN BE USED

( 3d PRINTING MATERIAL)

A major player in the climate change is the burning of fossil fuels. Meanwhile, plastic waste is devastating the Earth from within the ground and water. As a growing technology, 3D printing has the opportunity to move away from non-toxic, non-petroleum-based plastics to eco friendly material which is not only biodegradable but also environment friendly. The coffee ground waste can be used as a biobased product to make the filament which is used in 3d printers which can further be used to make home furnishing items and hot couture items. The coffee waste has cellulose in it, which will give additional strength. Apparently this will be material is pretty cheap. After all, it is a waste product that occurs after you reuse another waste product. There’s plenty of it, too, since apparently people drink about 2 billion cups of coffee a day.

A major player in the climate change is the burning of fossil fuels. Meanwhile, plastic waste is devastating the Earth from within the ground and water. As a growing technology, 3D printing has the opportunity to move away from non-toxic, non-petroleum-based plastics to eco friendly material which is not only biodegradable but also environment friendly. The coffee ground waste can be used as a biobased product to make the filament which is used in 3d printers which can further be used to make home furnishing items and hot couture items. The coffee waste has cellulose in it, which will give additional strength. Apparently this will be material is pretty cheap. After all, it is a waste product that occurs after you reuse another waste product. There’s plenty of it, too, since apparently people drink about 2 billion cups of coffee a day.

PACKAGING PURPOSES

It can be used for packaging purposes for anything and everything. Be it for gifting purposes as the package will smell good or to make customised shoe boxes which will also be use to keep the shoes by the used to keep it odourless.

It can also be packed in a paper or cloth package to use as a good scent.

Coffee deodorant package: on shoes, wardrobe, kitchen cabinets, refrigerator where can help deodorizing bad smell.

MEDICAL TEXTILE

Australian researchers have found out that the coffee bean pulp can heal wounds twice as fast as nature does. Caffeine and its metabolites theobromine and xanthine have been shown to have antioxidant properties. Keeping that in mind a textile using coffee bean and the process mentioned above in the document can be used to make wound healing medical textile which can be used as bandages.

CONCLUSION

We love coffee a lot but there is always a bit of a quirky feeling about the waste left over from our favorite beverage. It is degradable so that is fine but why wouldn’t we use it for something useful?

There is a theory that people around the world get the same ideas simultaneously, so I figured out that probably other people are thinking about this as well. I found a few very clever companies using coffee grounds for new products. So this research is based on that. I also found different functional properties which a coffee ground fabric would have and also various kinds of products made using coffee waste. Although I ideated some of the potential areas where this fiber can be used. But I feel with development and technological advancements many other useful products will be ideated just using coffee.

REFERENCES

- https://nat-2.eu/collections/nat-2-coffee-line

- www.singtex.com

- A novel approach of coffee ground fiber towards environment friendly textile – Ankita Singh Rao

- www.scafefabrics.com

- New opportunity for coffee waste- Charlie Bradley Ross/ 2017

- Sustainable Textile Innovations: Coffee Ground fibre– Alicia Carrasco Rozas

- Spent coffee grounds- Rocio Campos-Vegaa, * , Guadalupe Loarca-Pina

- https://fashionunited.uk

- https://sprudge.com/can-you-wear-the-coffee-you-drink-125116.html

- https://lessbydesign.org/2014/06/27/decafe-grinding-a-halt-to-ground-coffee-waste/