Combining lightweight design with effective warmth has been a persistent challenge in the apparel industry. “Weight plays a key role in performance clothing,” confirms Volker Schuster, Head of Research and Development at Outlast Technologies. “Heavy, bulky jackets can feel uncomfortable and restrict breathability, while lighter options often lack sufficient insulation.” To address this challenge, Outlast Technologies GmbH has developed a technology that makes it possible to incorporate the extremely light and insulating material aerogel directly into viscose fibres. This innovation significantly enhances insulation properties without adding weight, enabling ultra-lightweight, high-performance apparel. Independent testing confirms that Aersulate-treated fibers provide up to 35% better insulation than conventional ones, setting a new standard in textile technology.

Lightweight, Sustainable, High-Performance: A New Standard for Apparel

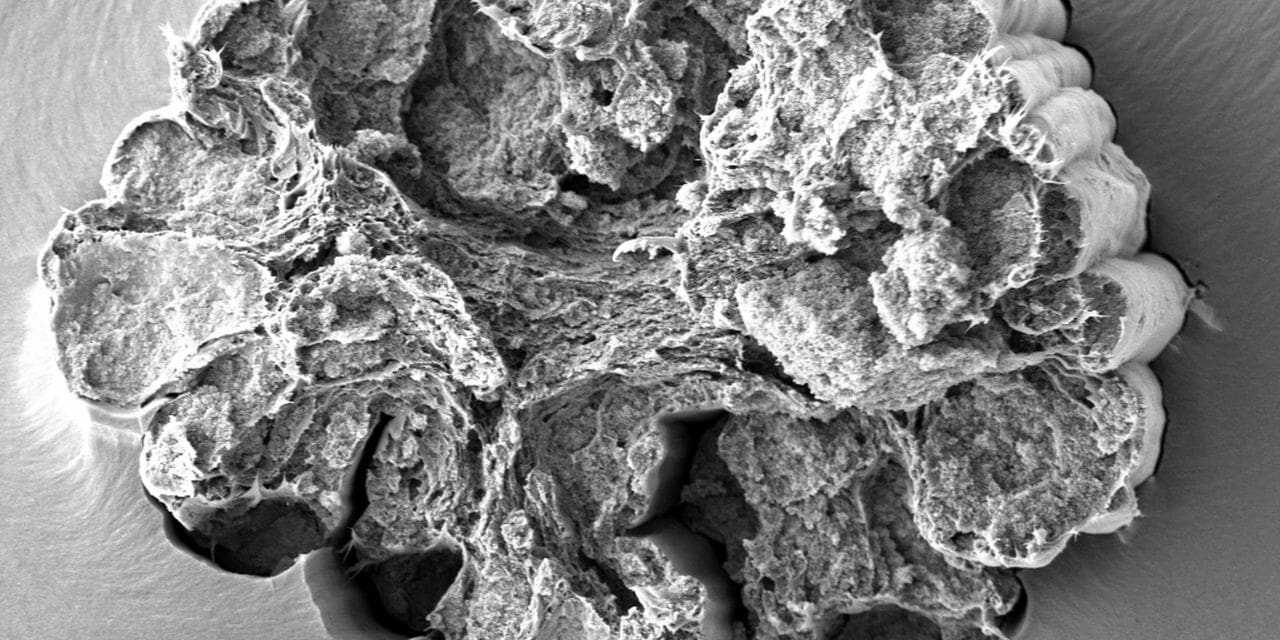

“Aerogel is a silicate-based solid that is derived from quartz sand and has a unique insulating effect,” explains Schuster. Aerogel’s outstanding insulating performance is based on its extremely porous structure, which is 98% air – the perfect insulation material. These special properties have made aerogel an essential material for NASA space missions for many years.

Now, Outlast has succeeded in utilising this challenging material for apparel with their new, patent-pending process. The company successfully achieved a remarkable high aerogel content, comprising 50% of the material’s

volume. This exceptional concentration allows brands to fully harness the properties of aerogel and appears to be extremely promising in the development of lightweight, sustainable and at the same time highly insulating fibres and textiles. Outlast has already seen successful use of its patented Aersulate technology in the past by applying the material very effectively to textile webs. While the fabrics are primarily designed for technical applications, the pleasantly soft fibers stand out as excellent filling materials for premium sportswear, jackets, ski pants, and workwear.

Unlike conventional insulation materials like foams, wadding, or nonwovens, that rely on trapped air for thermal regulation, aerogel encapsulates air within its fiber structure. This allows Aersulate products to maintain their insulating properties even under pressure, where traditional materials often lose effectiveness. As a result, they offer a significant advantage, providing consistent, reliable insulation in high-stress areas such as under backpack straps or at the knees and elbows. On top of that, Aersulate technology also supports sustainability: While Aerogel is derived from natural quartz sand, the fibers themselves are made from wood-based viscose, a renewable and eco-friendly resource.

Independent Testing Confirms 35% Better Insulation

An ISO-certified lab tested the insulation performance of Aersulate-treated viscose wadding against untreated wadding, with results showing a 35% improvement in insulation. This advancement allows apparel to be significantly lighter without compromising warmth, offering a major comfort and performance boost. Schuster concludes, “With Aersulate, we’ve fully harnessed aerogel’s potential for textiles, enabling ultra-light, high-performance, and sustainable apparel that meets growing demands for quality and functionality.”