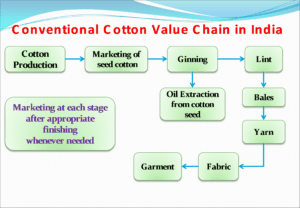

Value Chain for Cotton Fibre, Seed and Stalk:

An Innovation For Higher Economic Returns to Farmers and Allied Stake Holders

– Central Institute for Research on Cotton Technology (ICAR), Matunga, Mumbai

- Introduction

The Indian Textile Industry uses about 62% cotton as its raw material, unlike the global textile industry that has a 40:60 mix of cotton and man-made fibres. There has been a phenomenal increase in cotton production in India in recent years.

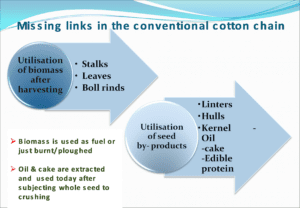

In the conventional value chain there are a few missing as well as weak links. Ginning is considered to be one of the weakest links characterized by excessive use of energy, presence of contaminants and trash and lack of facilities for quality assessment of individual bales. Although spinning sector is performing better with modern facilities, weaving/knitting sector still needs to improve in quality and product up gradation to meet the international standards. Further, processing such as preparatory chemical treatments of yarns and fabrics, eco-friendliness, energy use efficiency, and its treatment are factors that need immediate attention. In the handloom sector, workers are exposed to harmful chemicals and environment is also vitiated with chemical effluents in rural areas.

In this context, a World Bank funded project entitled, “A Value Chain for Cotton Fibre, Seed and Stalk : An Innovation For Higher Economic Returns to Farmers and Allied Stake Holder” was sanctioned by National Agricultural Innovation Project (NAIP) under Component 2 in consortium mode with Central Institute for Research on Cotton Technology (CIRCOT), Mumbai as lead center and Central Institute for Cotton Research (CICR), Nagpur, Super Spinning Mill Ltd., Coimbatore as consortium partners with the following objectives.

- To grow established cotton genotypes in the adopted villages with integrated production technology practices

- To reduce the level of contaminants in cotton by adopting appropriate on-farm and off-farm management practices and to label cotton bales with fibre attributes after appropriate ginning

- To prepare yarn, fabrics and garments in the modern mill, market and manufacture eco-friendly textiles in handloom sector by employing CIRCOT technology for bio-scouring and natural dyes

- To ensure additional income to farmers and alternate raw material to the industry by establishing cotton stalks supply scheme to board industries/ briquetting

- To demonstrate innovative scientific processing of cotton seed for oil extraction and value addition to its by-products

The present work addresses some of the above mentioned weak/missing links to increase the efficiency and economic competitiveness of cotton cultivation, processing and value addition. Best management practices encompassing INM and IPM modules were adopted to raise crop in three locations, namely, Nagpur, Coimbatore and Sirsa. Harvesting of contaminant free cotton was carried out by utilizing appropriate picking methods for seed cotton, on farm storage and transportation. The seed cotton was ginned and individual bales were tagged for fibre attributes and were spun. Cotton plant stalks were collected, chipped and transported to board industry for making particle boards. Edible oyster mushroom crop was raised on anaerobically pre-treated cotton stalks.