Abstract

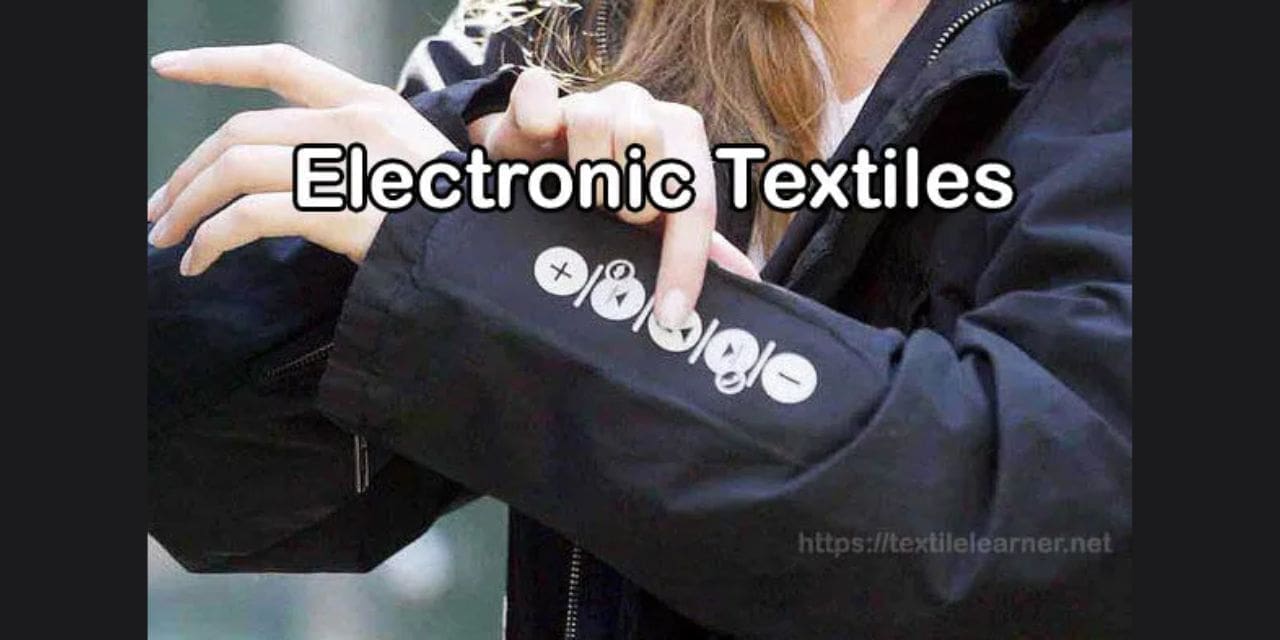

Electronics on textiles is a rapidly growing field. On a scientific basis, it can be treated as multidisciplinary: From the chemical formation of conductive layers and fibers, through textile combinations to obtain conductive fabrics; Through DC and conventional electronics to microwave and millimeter structures (filters, antennas, sensors, RFID, FSS etc.), but also the beginnings of computing.

In general, the construction of conductive structures can be presented in three main directions: (1) Applying conductive material to textiles. The main technics are screen printing and ink (or inkjet) printing conductive material. (2) Using conductive tapes or foils. Tapes and foils are of pure metals (copper, rare aluminum) or conductive textiles. (3) Using conductive thread and fiber. The main techniques are embroidery, knitting and sewing which gives conductive structures. There are also combinations between the mentioned ways. The most common is the use of conductive thread (fiber) as a thin conductor or for forming a short connection by sewing.

The application of conductive material and embroidery with conductive thread are fairly fixed techniques and there is little possibility of correction. The use of conductive tapes and foils, especially self-adhesive, enables correction and replacement of the structure without damaging the textile layer. Since the substrate is textile, or some plastic or rubber, it does not have a precise dielectric constant. As a rule, textiles are soft and do not have a uniform thickness, and they also have the problem of roughness. In addition to this, there is also the problem of cutting because often precise techniques cannot be applied. Due to these properties and conductive structures and substrates, the application is more demanding and must be adapted, as well as the simulation, to the nature of the material.

Topics (main topics of the special session; min 5)

– Fabrication of:

-Conductive fiber

-Conductive textiles

– Material application

– Applying conductive material to textiles.

– Using conductive tapes or foils.

– Using conductive thread and fiber.

– Connectors and connecting conductive areas

– Structures

– Conventional electronics

– Filters

– Antennas

– Sensors

-RFID

-FSS

– Simulation

Organizer

Dr.Dušan Nešić, Senior Research Associate

University of Belgrade, Institute of Chemistry, Technology and Metallurgy,

Centre of Microelectronic Technologies

[email protected]