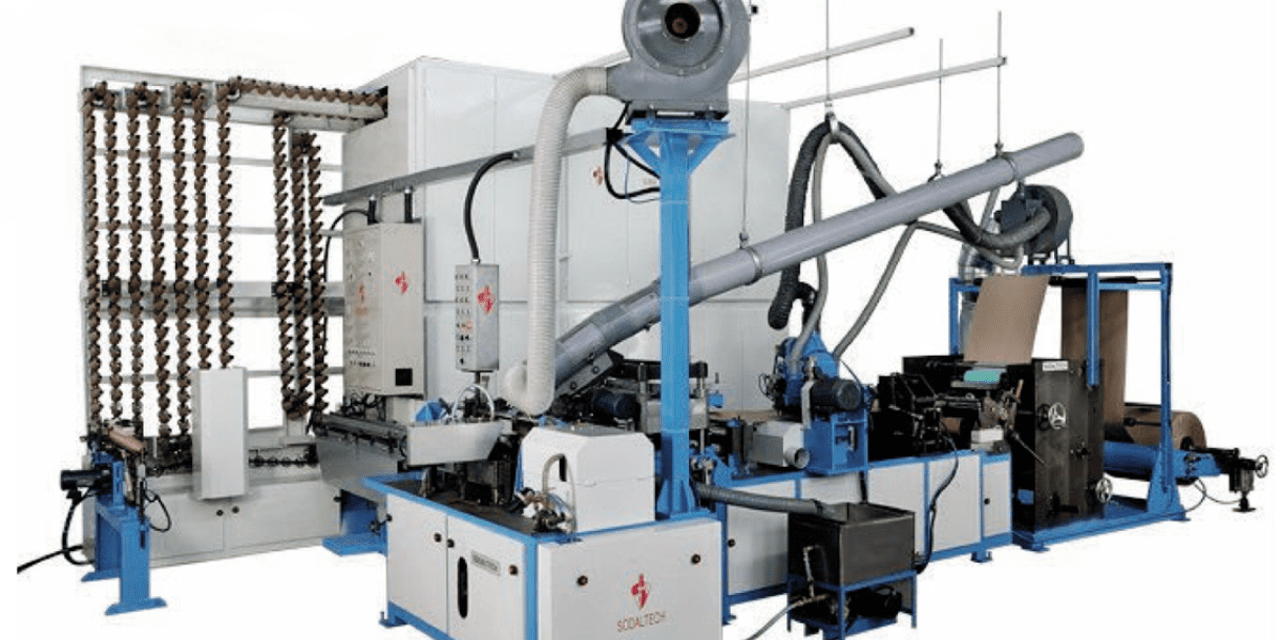

For the production of textile paper cones for yarn spinning, K. U. Sodalamuthu and Co. (P) Ltd., Coimbatore, offers its newest model high performance Automatic Paper Cone Plant. Depending on the quality of the raw materials, this production machine has a maximum rated capacity of 55 cones per minute.

The facility is perfect for producing superior cones with outstanding uniformity in dimensions to meet the strict requirements for use in autoconers from manufacturers like Schlafhorst, Savio, and Murata.

The machine is furnished with an imported servo drive system for the winding section and has a special gripper winding system to prevent sliding of cone patterns.

The machine is adaptable enough to create cones with different tapers, including those with 3 deg 30′, 4 deg 20′, 5 deg 57′, and 9 deg. employing mill board reels with the least amount of changeover time; deg 15′. The machine can be configured to run at the required pace depending on the paper quality thanks to programmable controllers. The facility has an automatic cone finishing equipment that performs the following tasks without human intervention:-

bull nosing base burnishing, nose end lubrication

- Velvet finishing

- Bottom grooving

- Notching for ‘y’, ‘u’, and ‘v’ shaped tail-end notches

- Nesting and automatic counting.

Extremely Strong Paper Core Winder

The business provides an Ultra Heavy Duty Spiral Paper Core Winder with an On-Line Fine Cutting System that can create extremely strong cores and tubes for textile yarn carriers for DTY (Draw Texturized Yarn) and POY (Partially Oriented Yarn) winding, Carpet yarn winding, Carpet storage cores, and fabric winding. etc. This latest model Spiral Paper Core Winder is fitted with independent motor drive to the winding drums to prevent slippage of winding belt. Reel Unwinding stand and glue tank are fitted with motorized movement system to save time in setting of sizes