ABSTRACT

Noise has become an increasing public health problem and has become serious environment pollution in our daily life. This indicates that it is in time to control and reduce noise from traffic and installations in homes and houses. Today a plethora of products are available for business, but none for the private market .With the continuing development of new technologies, particularly the trend towards faster, more powerful machinery, the environmental impact of noise is a matter of increasing concern, and considerable efforts are being made to finding effective means of noise abatement. The use of textiles for noise reduction is based on two major advantages of these materials, namely low production costs and specific gravity. This paper emphasis on the introduction,basic of acoustic ,sound Absorb ,material used, properties of acoustic,application of acoustic.

The definition of sound is a pressure change in air ,water,or similar elastic medium ,which can be perceived by the ear as a stimulus of hearing . Loudness and tone are two aspects of sound. Loudness is defined as the sound pressure expressed in decibel (dB), and tone is defined as the sound frequency expressed in Hertz (Hz). Human ear is not sensitive to all the sound frequency, and depending on its frequency and intensity, the sound may or may not be audible to the human ear.The range of 230–20,000Hz is the audible for human.

INTRODUCTION

Noise pollution can be defined as the excessive sound that can imbalance the activity level of human or animal life. Excessive noise has adverse effect on the physiological and psychological effects on human beings that can cause permanent hearing damage, increased stress, reduced efficiency at work, disturbance of the sleep pattern and interference in the communication. Noise is considered to have negative effect in a wide range of modern engineering areas. The problem of noise pollution becomes more aggravated in an enclosed environment. The competitiveness of products such as cars and washing machines is being considered by the noise level as one of the factors. This chapter describes the global usage of acoustic textiles and the reasons for increased usage. The rules and regulations in different countries of the world are also covered in this chapter. The methods used for noise control and various materials used for the same are briefly covered. In addition, a list of standards relating to acoustics and governing bodies around the world dealing with acoustics is also discussed.

BASIC OF ACOUSTIC SCIENCE

The act of hearing sound is an important communication and sensory medium with the surroundings. Sound is a wave that can be defined scientifically similar to the other mechanical waves in physics. The science of sound is acoustics that deals with the propagation of mechanical waves in various mediums such as solid, liquid and gases. As modern lifestyle includes the applications of acoustics in many fields, it is essential to understand the science of sound for people involved in acoustic applications. Various disciplines of acoustics include musical designs, vibration, noise pollution control, audiology, speech, vibration, underwater communication, audio signal processing, automotive acoustics, aero acoustics, structural acoustics, bio acoustics, ultrasound, vibration control and environmental noise control. This chapter deals with the concept of sound waves and basic terminologies associated with acoustic science. Sound generation and propagation is covered in detail. Furthermore, sound measurement and different sound classification systems are also covered.

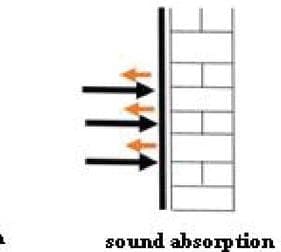

SOUND ABSORPTION

Sound absorption refers to the process by which a material, structure, or object takes in sound energy when sound waves are encountered, as opposed to reflecting the energy. Part of the absorbed energy is transformed into heat and part is transmitted through the absorbing body. The energy transformed into heat is said to have been ‘lost’.

When sound from a loudspeaker collides with the walls of a room part of the sound’s energy is reflected, part is transmitted, and part is absorbed into the walls. Just as the acoustic energy was transmitted through the air as pressure differentials (or deformations), the acoustic energy travels through the material which makes up the wall in the same manner. Deformation causes mechanical losses via conversion of part of the sound energy into heat, resulting in acoustic attenuation, mostly due to the wall’s viscosity. Similar attenuation mechanisms apply for the air and any other medium through which sound travels.

The fraction of sound absorbed is governed by the acoustic impedances of both media and is a function of frequency and the incident angle. Size and shape can influence the sound wave’s behavior if they interact with its wavelength, giving rise to wave phenomena such as standing waves and diffraction.

Acoustic absorption is of particular interest in soundproofing. Soundproofing aims to absorb as much sound energy (often in particular frequencies) as possible converting it into heat or transmitting it away from a certain location.

In general, soft, pliable, or porous materials (like cloths) serve as good acoustic insulators – absorbing most sound, whereas dense, hard, impenetrable materials (such as metals) reflect most.

RAW MATERIAL

Acoustic material play a vital role in the various area of building construction. In studio, class room, reading hall, cinema theatre, more concentration is required to listen, hence the acoustics treatment is provided so as to control the outside as well as inside sound of the various building until such that sound will be audible without any nuisance or disturbance.

SOME PROPERTIES SHOWN IN TABLE NO.01

The structural properties and air permeability values of five different non-woven surface used in the study are given in Table 1.

| Measured parameter | 100% PES | 100% r-PET | 100% rm-PES | 100% PP | 100% r-PP | |

| Mass per unit area (g/m2) | Mean (X¯) | 550 | 596 | 519 | 509 | 500 |

| Standard deviation (SD) | 8.14 | 12.10 | 27.27 | 10.92 | 4.81 | |

| CV (%) | 1.48 | 2.03 | 5.25 | 2.15 | 0.96 | |

| Thickness (mm) | Mean (X¯) | 4.04 | 2.95 | 3.17 | 3.60 | 4.55 |

| Standard deviation (SD) | 0.16 | 0.09 | 0.30 | 0.10 | 0.10 | |

| CV (%) | 3.93 | 2.89 | 9.46 | 2.67 | 2.28 | |

| Air permeability (l/m2 s) | Mean (X¯) | 1136 | 1270 | 600 | 875 | 1536 |

| Standard deviation (SD) | 57.71 | 116.40 | 112.13 | 148.66 | 69.14 | |

| CV (%) | 5.08 | 9.17 | 18.66 | 17.01 | 4.50 | |

| Fabric density (g/cm3) | Mean (X¯) | 0.136 | 0.202 | 0.164 | 0.141 | 0.110 |

Table 1.

Properties of non-woven fabrics used in the study.

TYPES OF ACOUSTIC MATERIAL

Acoustic plaster.

Acoustic tiles.

Perforated plywood.

Fibrous plaster.

Staw board.

Pulp board.

Compressed fibre board.

Hair felt.

Cork board slabs.

Foam glass.

Asbestos cement boards.

Thermocoal.

Foam plastic.

Chip boards.

Gasket cork sheet.

Hair felt.

Acoustic foam.

APPLICATION OF ACOUSTIC TEXTILE SOUND ABSORPTION MATERIAL

Almost every textile has some potential for acoustic function.

In fact textiles are used in many application involving acoustic, Including:

- Upholstery

- Acoustic panels

UPHOLSTERY IN CONCERT HALLS

Acoustic Noise Reduction Blankets

- The vinyl-coated facings on the noise reduction blankets are dirt and resistance ,cleanable and designed for high-use industrial settings.

- The audio seal Acoustic Blankets offers a powerful combination of noise reduction and durability.

- AQFA-10 Insulation Blankets offer strong sound absorption Via quilted fibreglass enclosed heavy-duty aluminized vinyl exterior.

Trunk

- A trunk should be constructed in a manner which prevents the airborne noise(activated by the body) as far as possible from the trunk and thus the interior.

- Extremely absorbent textile molded parts as well as textile flat parts are installed to keep away any noise e.g. of the exhaust system ,from the rear passenger compartment.

ROOF PANELLING

- In order to improve pote -tial of the roof paneling ,a two-layer PET construction would provide a solution:on the visible side a PET is lami-nated to an air permeable PET carpet bonded by thermal activated Bico/PET fibres.

SEATS

- The car seats have large surface area have s, and they even absorb airborne noise in low frequency ranges ,if covered ,with an air permeable of their thick layers.

ACOUSTIC PANELS FOR WORKSTATIONS

The acoustic as a panels used for decoration as well as acoustic purpose, the different panels products used for acoustic purpose as below

POLUPHON POLYESLER PANLES

Polyester Panels are a great choice for better soundings classrooms.

They have many advantages over other acoustic products

- The acoustic wall panels are made from 100% polyester (60%PET-recycled fibre and 40%-virgin fibre)and are 100% recycled

- Great Sound Absorption,NRC.75

- Cost effective and easy to install.

ACOUSTIC CEILLINGS SYSTEMS

- Acoustic material work to control the sound quality in a room by controlling the absorption and diffusion of sound waves.

- Suspended acoustic ceiling system refer to acoustic panels or tiles suspended by an exposed or concealed or concealed ceiling grid. The tiles themselves can be made fibreglass ,mineral fibre ,wood, or metal.

- A suspended acoustic ceiling is a perfect example of an opportunity to use acoustic textiles for board-frequency sound absorption.

3D FABEIC PANELS

- The panels are made in a modular style and covered in fabric from Macquarie fabric to give a 3dimensional look on the wall.

- It is easy to install and reduce cost of installation.

VISUAL IMPORT ACOUSTIC PANELS WITH NETWORK “ TRANSLUCENT FABRIC”

- Visual impact panels have been developed in conjunction with textile mania to create an acoustic panel with a new unique fabric.

- The panels are designed to be installed on wall or ceilings in office and public space to reduce reverberation and improve sound quality.

- Network is translucent industrial mesh fabric with excellent dimensional stablilty, that can be used for work station clamp on screens to controls airflow, diffuse sound and provide privacy .

- Quiet-space Acoustic Fabric.

IN LIST THE APPLICATION OF ACOUSTIC TEXTILES

- Public Buildings

- Industrial Plants

- Inplant Offices

- Loud, stationary Noise Sources

- Enclosable Noise Sources

- Outdoor Noise Sources

- Compressors

- Machine Enclosure Curtains

- Inplant Noise Baffles

- HVAC Applications

- Stamping Presses

- Conveyors

- Pipe and Duct Jackets

- Inplant Noise Curtains

- OEM Applications

- Auditoriums

AUTHOR:

Mr. Karan Abasaheb Jadhav

Department of Textile Technology,

DKTE Society’s Textile & Engineering Institute,

Ichalkaranji, Maharashtra, India.