Rabatex, Ahmedabad-based pioneer in sectional warping since 1962, has made rapid strides in technology and today has emerged as a leader in warp preparation machinery and sectional warping machines. Its machinery are highly advanced technological wonders, surpassing the advancements made by imported machinery. Rabatex Industry is the largest supplier of premium sectional warping machines in India, having already installed about 3200 Sectional Warpers and about 5600 Trollies installed across the countries gloablly.

Rabatex, Ahmedabad-based pioneer in sectional warping since 1962, has made rapid strides in technology and today has emerged as a leader in warp preparation machinery and sectional warping machines. Its machinery are highly advanced technological wonders, surpassing the advancements made by imported machinery. Rabatex Industry is the largest supplier of premium sectional warping machines in India, having already installed about 3200 Sectional Warpers and about 5600 Trollies installed across the countries gloablly.

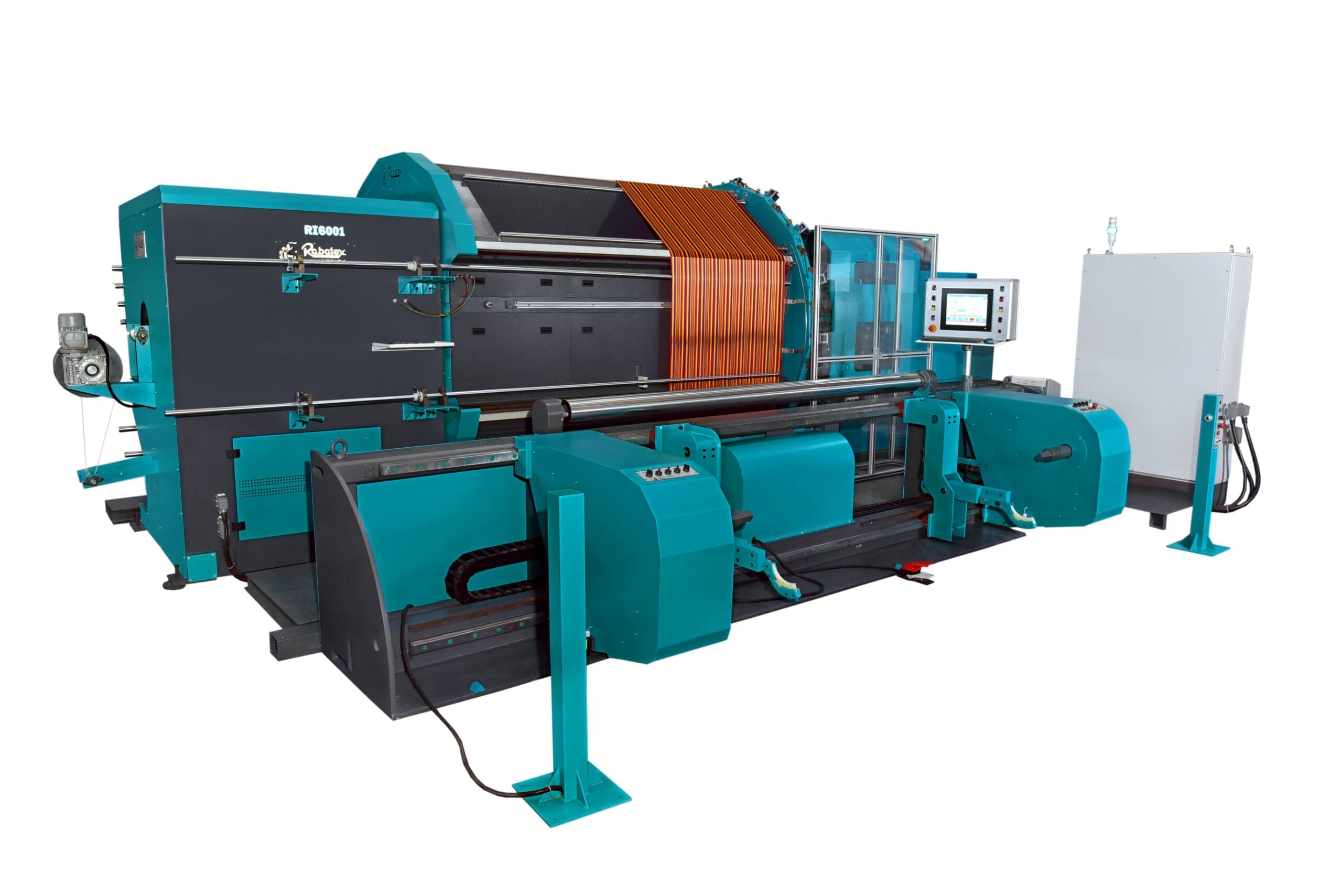

RABATEX have now come out with a different types of sectional warping machine-like High-Speed Sectional Warping with 3 axis servo, single axis servo machine, and manual machine to cater to different tiers of clientele. Whether it is a small weaving unit or latest high speed weaving set-up in corporate sector, Rabatex has solutions for any kind of warping requirements. When the warping is done finely the weaver seldom worry about the final product at the weaving stage. Good warping is considered as half weaving done.

Rabatex experts have been constantly in touch with technical experts in textile industry across the world over about their actual requirement with respect to value for investment as well as product output expectation. With patience and creativity, Rabatex Team has made analysis need of future demand and customer expectation as well as global opportunity of Indian Textile Fabric Manufacturing Industry. It is continuously exploring highest opportunity for textile industry to display their capability, creativity, and value addition.

Rabatex has made rapid advancements in exports. It has been widening its presence in global markets and constantly increasing its market share. The exports now have nearly doubled as compared to the FY 2021-22. This shows the wide acceptance for Rabatex’s products in the international market. Key markets in which Rabatex witnessed higher growth include USA, Canada, Turkey, Russia, South Africa, Indonesia, Bangladesh, etc.

Merits of Rabatex Sectional Warping Machine

Merits of Rabatex Sectional Warping Machine

With the Rabatex Sectional Warping Machines multi-coloured warp with complicated pattern can be successfully prepared. The advantages is that only one beam is in one set, and so, leading to less inventory & handling of beam. Other advantages are:

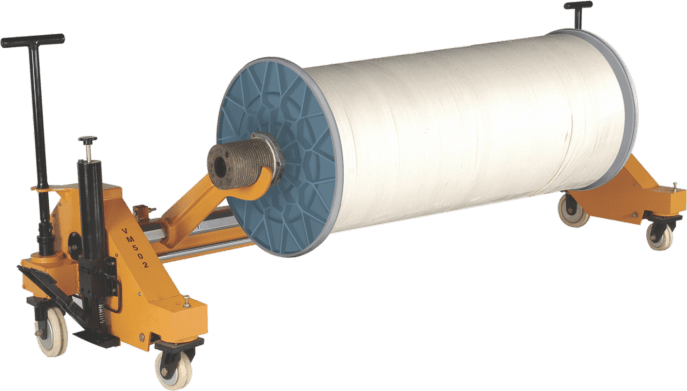

– A sectional warping machine consists of three basic units, which are the creel, winding drum, and beaming unit.

– In section warping, warp yarns are organized into yarn bands (sections), each having the same warp density as per the weaver’s beam.

– where there is no need for any application of starch, such as two-fold cotton or woollen/worsted warps

– Less yarn waste at warping.

– Short length warp can be easily possible with this warping

– Less nos. of packages are required for warping. So, less inventory of packages.

The final beam prepared from the sectional warping machine must have following characteristics: Equal density throughout the width; equal tension throughout the width & from starting to the end of the beam; no missing threads i.e., having required total number of threads from beginning to the end of the beam; and insertion of leases for the next process.

Indirect Warping / Sectional Warping Machine is one of the important processes of textile weaving where equal length of yarn is wound first in small sheets or sections on a drum. After that, it is transferred to the beam from the drum in the form of a sheet. This type of warping is a two-stage process which is used to produce fancy fabrics by using colour and weave effect. Sectional warping is also known as pattern warping, indirect warping, drum warping and band warping

Why is Sectional Warping Machine required or considered heart of weaving?

Why is Sectional Warping Machine required or considered heart of weaving?

On the weaving machine, the threads (ends) lie parallel to each other from the warp beam, guarantees the separation of the warp ends at the drop wires & in the reed without difficulties, facilitating clear shed formation and effective weft insertion resulting in higher productivity. Cross ends or snarled ends are avoided as these will increase the friction & tension, which leads to fabric quality problems or thread breaks. Also, sectional warping reduces the yarn inventory & so ultimately reduces the yarn waste. With the help of sectional warping machine, one can get the maximum production even with short length warp.

Customer satisfaction is the core and Rabatex has built the machines and services around this core. Like today, the company is always looking forward to staying abreast of technology by delivering quality products to its customers. Maintaining the leadership position in domestic market is the key focus, Rabatex expects to emerge a global player of greater volume in the years to come and capture a considerable share of the global market too.