International technology group ANDRITZ will be presenting its innovative nonwovens production and textile solutions at Techtextil in Frankfurt, Germany, from June 21 to 24 (Hall 12, Booth B99). The broad ANDRITZ product portfolio covers state-of-the-art non-wovens and textile production technologies, such as air-through bonding, airlay, needlepunch, spunlace, spunbond, wetlaid/WetlaceTM, converting, textile finishing, recycling, and natural fibre processing. For Techtextil, special focus lies on technologies for textile recycling, needlepunch, airlay, wetlaid glass fibres and textile calendering.

Andritz textile recycling technologies based on tearing

With the acquisition of ANDRITZ Laroche SAS, ANDRITZ has expanded its product portfolio to include airlay and recycling technology as well as bast fibre processing technologies. Complete recycling lines for post-consumer and industrial textile waste to produce fibres for respinning and/or nonwoven enduses are one focus of this product range. Customer awareness and regulations are forcing clothing brands to recycle their textile waste in their own products. Recycled fibres can also be used in the nonwovens industry for various applications, for example in the automotive industry, for insulation, mattresses, and furniture felts.

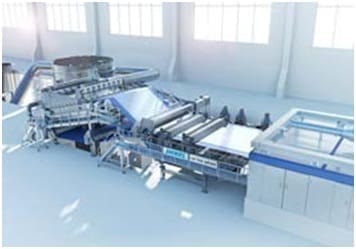

ANDRITZ Laroche offers a complete process range of tearing lines from 50 up to 3,000 kg/h, which can be used for almost all types of pre/post-consumer textile waste. The aim is to preserve the character of the original fibres, for example cotton, by maximizing fibre length, strength and feel.

The EXEL and JUMBO EXEL tearing machines from ANDRITZ are user-friendly and equipped with tailor-made automated solutions to remove the non-textile parts from post-consumer waste and unsold items. The EXEL tearing machine has a production capacity of 400 to 800 kg/h depending on the raw material for spinning quality.

The JUMBO EXEL tearing machine has a high production capacity of 600 to 1,200 kg/h depending on the raw material for spinning quality. This technology enables complex industrial waste to be processed into fibres such as trunk liners, door trims, floor and dash pads, and various needlepunched felts. A team of experts assists ANDRITZ customers in conducting customer-specific trials at the state of-the-art technical centre of ANDRITZ Laroche, in Cours, France.

Cutting-edge solutions for durable applications

The use of nonwovens in the automotive sector has increased dramatically in recent years. Based on decades of experience, ANDRITZ develops cost-efficient and reliable turnkey needlepunch and airlay lines.

The recent boom in the market for durable nonwoven products led ANDRITZ to develop its PA3000 elliptical pre-cylinder to meet the demand for higher capacities and lighter products. This state-of-theart equipment consists of an optimized pre-needleloom cylinder for the production of light webs and provides greater speed and width. The lack of friction between the web and the rolls provides a perfect appearance. In addition, the automotive industry is shifting its focus to green technologies, and this has a direct impact on the properties of nonwoven parts in vehicles. Thanks to the ANDRITZ needlepunch processes and web profiling, manufacturers can provide the most suitable fabrics for this industry’s requirements and maximize ROI.

Another focus is the ProWinTM technology for profile weight correction in the needlepunch industry. This device is used to optimize processes, provide a faster return on investment, and save raw materials. The unit combines the well-known systems ProWid and ProDyn, enabling even better performance. ProWin minimises the level of instantaneous acceleration as well as the maximum internal speed. As a result, the same machine can run faster with less mechanical stress. ANDRITZ will also be presenting its ProWin technology at the VDMA spotlight talk, to be held at 10:30 am on June 21 at the VDMA booth and which will also be live- streamed.

Moreover, the airlay technology also plays a major role in durable nonwovens, such as in the automotive industry, building insulation, carpet underfelt, the mat- tress industry, and furniture applications. This process includes blending, metering, opening, the airlay process and finally, mat consolidation, by needling, thermobonding, a combination of both, or by spunlacing. ANDRITZ offers three different types of airlay: Airlay Flexiloft, Airlay Flexiloft+, and Airlay Resinfelt.

ANDRITZ Airlay Flexiloft and Airlay Flexiloft+ have been designed to form mats from all types of fibres, from short, recycled fibres to long and coarse natural fibres, and from blends with non-fibrous components, such as plastic, foam, wood chips, and many more. Used fibres and blends within different weight ranges can be processed on these lines, depending on the line configuration. Line widths range from 1.5 m up to 4 m. Airlay Resinfelt has been designed for thermoforming processes in the automotive and appliance industries. Manufacturers can offer weight ranges from 500 to 2,500 gsm over 2.4 m working width. Airlay Resinfelt retains the advantages of true air-forming technology and is especially designed to add resins to the mat, which is then semi-cured in a steam oven.

Customers are welcome to conduct trials together with our experts and compare the different options available in the technical centre for needlepunch processes at ANDRITZ Asselin-Thibeau in Elbeuf, France, and/or on the airlay pilot line at ANDRITZ Laroche in Cours, France.

Complete wetlaid systems for glass fibre

Nonwoven end products based on glass fibres can be found almost everywhere – in ceiling tiles, cushion vinyl flooring, insulation, wallpaper and surface coverings, geotextiles, batteries, and, of course, roofing materials, as well as in many other applications. The market for glass-fibre mats is growing due to an in- creasing amount of construction and civil engineering work worldwide as well as the great variety of applications for this material. ANDRITZ offers a complete wetlaid production line, from low to high volume, to produce glass-fibre mats – the ANDRITZ neXline wetlaid. Different types of lines are available depending on the capacity level. However, they all comprise stock preparation, wetlaid forming, binder application, flat dryer, and winder and are perfectly matched to the customers’ needs.

The entire ANDRITZ Nonwoven team is looking for- ward to welcoming customers in person to its booth B99 in hall 12 and online in the “ANDRITZ Teleport” virtual booth.

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cor- nerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,100 employees and over 280 locations in more than 40 countries.