P. Athane 1 Dr. Mrs. A. A. Raybagi2 Dr. S. R. prasad3

Assistant professor Assistant professor Assistant professor

Department of E & TC, DKTES’ Textile & Engg. Institute, Ichalkaranji.

Department of Fashion Technology, DKTES’ Textile & Engg. Institute, Ichalkaranji.

Department of E & TC, DKTES’ Textile & Engg. Institute, Ichalkaranji.

Abstract: Artificial intelligence describes the simulation of human intelligence in intelligent devices that have been designed to act and think like people. AI has considerable potential to reduce labour time and costs, automate processes, improve quality, optimize designs and increase customer service. AI assisted automation not only improves machine efficiency but also overall industrial operations. Computer algorithms and machine learning have been used to aid the majority of the textile testing process. AI can also be used in the fashion and apparel industry to improve product design and optimize the production process. This paper aims to highlight AI applications ideas and reviews innovations in the textile industry. And learn more about artificial intelligence’s effects and importance on the textile business. We conducted a thorough literature review of research article to achieve this goal.

-

Introduction:

Artificial intelligence describes the simulation of human intelligence in intelligent devices that have been designed to act and think like people. AI has completely changed the fields of engineering, physics, medicine and management in this era of information technology. In recent years, AI has been employed in many fields to address complicated problems. Textile industry is one of the oldest and most significant industries in the world. The development of AI has changed the textile business in recent years. To meet rising customer demand, the textile industry is becoming more automated. The traditionally labor-intensive textile sector has undergone significant change due to the advent of new technologies like artificial intelligence and the internet of things (IoT). This paper aims to highlight AI applications ideas and available innovations in the textile industry.

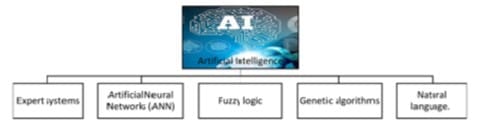

The idea of artificial intelligence is built on core tasks like predicting, machine vision, categorization, inspection, and detection. These are all mostly human tasks that are tedious and have ambiguous results. Artificial neural networks, fugitive logic, algorithms, and natural language are examples of technologies that fall under the category of expert systems that AI can use to improve the accuracy and efficacy of these basic operations. In textile technology, AI is still largely underutilized. The sophistication, skill requirements and return on investment are the most likely causes of the limitation of technology adoption.

The textile manufacturing sector must also figure out how to customize the manufacturing process in order to move toward industry 4.0. A number of intricate and well-organized operations, including spinning, weaving, dyeing, printing, and finishing, as well as the production of clothing, make up the textile manufacturing process. Innovation and the desire to follow trends drives the evolution in fashion industry. As technology develops, AI has become a critical component which is used to determine the direction of the fashion and textile industries. Artificial intelligence can be used to streamline production procedures and cut waste, improving the sustainability of the textile sector. AI has made it possible to offer a better experience for “Smart Clothes” which use IoT and electronic sensors. The automation of various instruments by the application of AI in spreading, cutting, sewing and material handling can reduce the production cost and minimize faults in the overall textile production. The application of the AI can handle the production process without error. As a result, over the last decade, the use of AI is rapidly growing in textile industries for various applications. AI can monitor production lines and identify defects, predict machine breakdowns and optimize production schedules. One of the main and widely used AI tool is (ANN) Artificial Neutral Network, AI is used in number of application such as dentification of defected fabrics, pattern inspection, color matching, sewn seam , CAD systems also production planning and control.

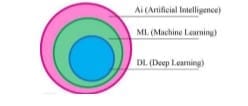

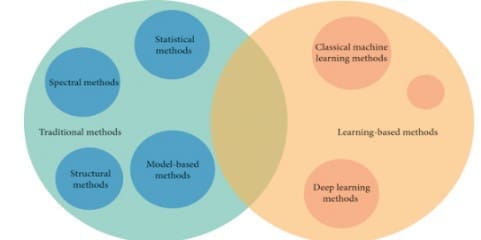

Figure 1: Artifical Intelligence (AI), Computer Vision (CV),

Machine Learning and Deep Learning (DL)

The terms AI, CV, ML and DL are often used mutually. Luce stated that AI itself imitates the working of the human brain. Machine Learning has the ability to produce output by input data information while deep learning requires a lot of data to train the model to be able to answer the query data. Computer Vision is ML that use deep learning to analyze visual data. In this case, thousands of photos of people with clothes, both from online shops and street photos, can be used by CV as sample data for analysis. ML is classified into 2 types; supervised, unsupervised, which are commonly used for object detection, analysis and prediction. Computer Vision is commonly used in the fashion industry because CV performs visual data analysis with algorithmic methods. CV realize visual data is different from humans, a photo for example is seen as a pattern arrangement of algorithmic numbers.

Big data is a large amount of information. But, more deeply, it refers to an extensive collection of unstructured or structured data that has been digitally compiled and organized in a manner that allows humans to quickly capture valuable insights. However, only big data will not be sufficient; for desired results advanced analytical tools such as (AI) will be required along with big data. The more data fed into these (AI) algorithms, the higher their performance. In the AI environment the garment and textile industry can fully analyze the data collected by big data.

-

Applications of AI in textile

2.1 Innovation process in AI

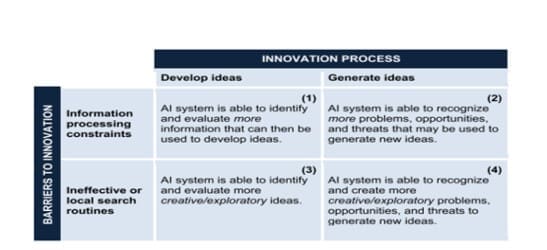

Fig.2 Application areas of innovation process in AI

There are several AI applications that relate to the framework in Fig. 1. These AI applications are able to process much more information to generate novel ideas and opportunities and to overcome the barriers to innovations.[1]

2.2 Fabrics based neural network workflow

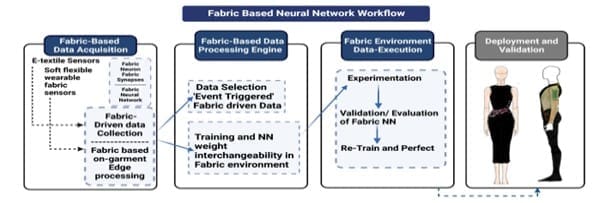

Not only will new AI design fabrications begin to emerge, but also new fully fabric driven data acquisition and data processing approaches potentially implemented by new AI best practice, standards and methodologies.

Fig.3 Fabric based neural network workflow

Key features of fabric-based AI algorithms need to consider during response time, processing capabilities, size and also learning. Fig. 2 provides an overview of the key components for a textile driven AI workflow facilitating fabric-based data acquisition, a data processing fabric-based engine, data execution in a fabric environment and also deployment. From an e-textiles point of view each of these four AI pillars need further research and deep analysis to consider how such a workflow can operate and function in a textile fabric environment. How such data sources can be collected and processed by integrated intelligent textiles sensors in a fabric environment, need to be observed. The concept of a fabric neuron and fabric neural network embedded in a textile environment are being considered, so how can this support advanced data selection and fabric edge driven computation where fabric based algorithmic learning/training can be included and executed in real time.[2]

2.3 Fabric Defect Detection Methods

Fabric defect detection algorithms are roughly classified in two categories in this study, traditional algorithms and learning-based algorithms, as shown in Fig.3. Most of the traditional algorithms are based on feature engineering with privious knowledge, covering statistical, structural, spectral, and model-based methods. The learning-based algorithms can be further divided into classical machine learning algorithms and deep learning algorithms. Machine learning uses mathematical algorithms to learn and analyze data to make predictions and take decisions in the future, which has been widely utilized in recent years and accomplished stratifying results in various disciplines and industries.

Fig.4 Traditional algorithms and learning-based algorithms

To realize a better detection result, different algorithms are combined by the researchers. Accurate, efficient and robust fabric defect detection algorithms are necessa`ry to develop fully automated web detection systems. With the development of new object detection algorithms, computational capabilities, sensor technology computer-vision based textile defect detection techniques will continue to advance at a high speed.[3]

Fig.5 Classification of AI

2.4 Classification AI in textiles industries:

AI is classified in five sections as shown in fig.4. The ANN methodology uses backpropagation with a variable learning rate and several linear regressions. It can help with fiber grading, yarn quality prediction, fabric issue diagnostics and dye recipe prediction. It’s applicable in various aspects of the textile industry, from raw materials to finished textiles. Adaptive neuro-fuzzy inference system (ANFIS) has recently been applied to assess yarn characteristics. The textile sector also uses ANN to predict utility attributes such as moisture, heat transfer rate in fabrics and air permeability. The use of neural networks in textile coloring and printing which predicting dye formulas, matching colors and identifying dyeing faults, has reduced the need for human contact

The ANFIS model blends fuzzy control with neural networks. Fuzzy control uses a learning and computational neural network. However, it also provides high knowledge and fuzzy rules for use in neural networks. The ANFIS model is trained to predict yarn tenacity and unevenness using an experimental data set. Five statistical metrics: correlation coefficient, mean absolute percentage error, root-mean-square error, co-efficient of efficiency and variance performance index are used to evaluate prediction accuracy. Humans, on the other hand, are prone to making mistakes. As a result, neural networking and machine learning have become increasingly significant. [4]

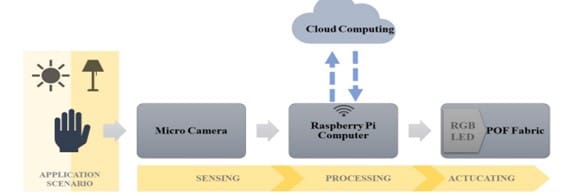

2.5 Gesture recognition based on computer vision:

It is the key mechanism and referred as system of electronics integrated into the textile for real-time detection and recognition of hand movements from digital images or video inputs to realize the interaction between humans and computers. High-dimensional data from real world situations can be extracted and processed in the form of numerical and symbolic information for subsequent processes of decision making. Deep learning is a branch of machine learning where gestures are learned from static and dynamic hand images via existing algorithm architectures, such as recurrent neural networks (RNN), long short-term memory (LSTM), and convolutional neural networks (CNN). Multiple layers of networks are adopted in deep learning to increase the prevalence and accuracy of the gesture recognition mode. An open-source AI model based on a deep learning algorithm was adopted to input gesture images. To achieve gesture recognition The Raspberry Pi 4B hage potential to be developed with embedded AI to achieve gesture recognition. Open source AI models promote innovation by eliminating much of the time, labour and financial costs involved in model development. As Fig.5 below shows, in the sensing stage, a micro single-camera takes discontinuous photos of hand gestures after every 45ms . In the processing stage, the Raspberry Pi 4B computing unit controls the micro camera in sending and uploading the gesture images to the Baidu server to process the results of recognition via the internet. In the actuating stage, the colour of the POF fabric changes, via the coupled LED light source, according to the results returning back to the Raspberry Pi 4B from the Baidu server. The correlation ship between the POF fabric colours and different gestures is pre-programmed in a repeated linear logical program.

Fig. 6 Operation of the sensing-processing-actuating framework. [5]

2.6 The automation with applications of artificial intelligence in textile field:

In textile manufacturing it is much popular due to the technical developments and the use of modeling and simulation. AI is finding a place with textile manufacturers, helping with visual inspection jobs like color matching and pattern making. It is used to assist with quality control, supply chain management, and an overall improved customer experience. The automation of various instruments by AI application in spreading, cutting, sewing, and material handling can reduce the production cost and minimize defects in overall textile production. CAD is an AI sub-set that enables computerized patterns to be produced in which designers can digitize and form the basic structure of the patterns. CAD is used to cut patterns, where 3D pictures of cloth and concepts are provided, which makes it easier to display. Other classical AI applications include fault detection, pattern checking, and color matching for textile production. In the textile industry, AI is being used to create designs, select colors and patterns, and even 3D-print fabric. It is also used to create textile fibers and fabrics that are stronger, more durable, and have exceptional properties. The major raw material for the clothing industry is fabric. The fabrics are selected based on the type of garment and their end-use applications. AI is used gradually to different stages of a sewn seam, design development, in PPC, fabric spreading, cutting, bundling, in various sewing operations, pressing, ironing, packaging, quality control, SCM, etc.

AI is being used in the textile industry, including:

1. Automated design: AI can be used to create new designs for textile products automatically.

2. Manufacturing: AI can be used to help automate the manufacturing process of textile products. This includes tasks such as fabric cutting, sewing, and printing.

3. Quality control: AI can be used to help improve the quality control of textile products. This includes identifying defects in products and making sure that they meet customer specifications.

4. Sales and marketing: AI can be used to help with sales and marketing of textile products.

There is a high demand of good quality products thus results in the usage of automated artificial intelligence in the textile production process with popular technical developments and the implementation of modeling and simulation. By adapting AI, we can reduce the number of faults which can eventually reduce production cost, it can be implemented in all the stages of manufacturing. The use of AI has its existence in different stages of developing sewn seam designs, in PPC, pressing of fabric, bundling, in different sewing processes, pressing of fabric, ironing, packaging, in quality control, SCM, etc.

Recent applications of ai in textiles: Cognex – Fabric pattern Inspection Cognex learning turns around the automatic inception of complex fabric patterns it incorporates the process of knitting, braiding, finishing and printing. Without the use of any complex software development, the software algorithm trains itself to create new models. During the inspection the Cognex identifies and reports the defective areas on the fabrics. For the recognition of fabric patterns the use of Cognex ViDi platform has been applied. Thus, with the working of Cognex it is easier to save cost as well as time with the efficient inspecting of the quality of the end product. The cameras can also be installed to aid the inspection system with a virtual programming. The industry and we can also upload numerous images of good and bad samples. The weaving pattern, colors, yarn properties and a few imperfections that are tolerable are noticed and these processes are performed by the Cognex.[7]

-

Application of AI in fashion and apparel

3.1 Deepfashion:

Deepfashion is a data set particularly made for fashion analytic needs, containing a collection of photos classified by type of garment or style, such as jeans, tie dye t-shirts, or baby doll dress styles. The use of the same data set with different algorithms and statistics can analyze and predict trends or industry needs within the management process utilize minimal human intervention, from research to distribution. − Sustainable fashion. The fashion industry is the largest contributor to pollution and waste in the world; therefore, sustainability should be applied in this industry to every stage of its production process, starting from R&D, manufacturing and distribution. Basically, object detection annotates the photos the same way humans do, but when it comes to thousands of photos, it can perform faster and more efficient than human annotation. Methods: This research is an introduction to Ai and how it can be implemented in the fashion industry, as a green alternative compared to the prevalent one. It is necessary to review the literature from three scientific sides, namely from computer science, fashion management, and fashion and sustainability. Ai implementation in fashion industry becoming more sustainable. [8]

3.2 Application of artificial intelligence in clothing production automation system:

The traditional manual clipping is inefficient less in accuracy. Using machine vision technology, the robots can accurately distinguish the size and shape of the cutting piece, and then cut it as per the scanning results. The main requirement of this process is that the robots can accurately judge the contour of the cutting piece, extract the data and record them on the computer. At present, many algorithms for contour extraction through machine vision are available. The mainstream ones are edge detection based on image edge extraction, edge detection based on mathematical morphology and so on. Image edge extraction is used to analyze and record the color, brightness and other features of the target image, and then mark and extract the location of the two points where the difference of some feature parameters between the measurement and the standard is too large. Edge extraction can be obtained by convolution with the help of differential operators. The commonly used operators include Sobel operator, Prewitt operator, Roberts operator, LOG operator and Canny detection operator. At present, contour extraction is mainly used in the fabric printing process. In mathematical morphology the image is regarded as a collection of a series of points, and then these points are calculated by morphological method to separate the cut pieces from the background, and finally extract them. Both methods have their own advantages and disadvantages, and enterprises can select anyone according to their own workshop conditions .Automatic Cutting Sorting System Based On Artificial Intelligence Before sewing cut pieces into garments piece sorting is completed. In this process, many pieces mixed together need to be classified. In fact, we can realize automatic sorting using AI and IOT technology. Compared with manual sorting, this method greatly saves labor costs and time. At the same time, the QR code will also be hidden in the inner side of the clothes during sewing, which will not affect their appearance.

Sewing Automation Based on Intelligent Robots. Although today’s sewing machines can simplify the sewing process a lot. The operators still need to control the cutting pieces to pass through the sewing machines smoothly and evenly. Full automation of this process can be achieved by programmable intelligent robots. It only needs to upload the mobile cutting instruction to the robot in the form of programming and make it run successfully. However, during automatic operation it is difficult to adjust the speed of the sewing machine. There are many ways to solve this problem. [9]

In the AI environment the garment and textile industry can systematically analyze the data collected by big data, better understand the supply and demand of the garment and textile market, provide strong data support, and find out the effective connection between huge information resources and garment production. Textile companies can rely on algorithms and big data to clearly understand market trends and develop products that meet market and customer requirements in a timely manner. The AI can not only use popular e-commerce and mobile platforms in apparel retail manufacturing to provide more online customer suggestions by understanding customer information.

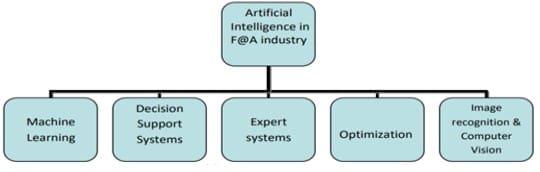

3.3 AI techniques characterizations

Fig.7 AI techniques characterizations

As shown in Fig.6 the AI technique characterizations is divided in number of sub sections

Machine Learning: Machine learning is a technical process in which computers are trained to do assigned jobs without human intervention and to learn from the patterns in the data itself. Mathematical models are built to identify and predict hidden ways to make future decisions based on historical data. There are two classifications of machine learning: supervised and unsupervised learning. Supervised learning is a parametric model, and with inputs independent variables and dependent variables, a supervised model’s performance can be enhanced by iteratively optimizing the model parameters. However, unsupervised learning models only have inputs independent variables, with the main task of grouping similar data points. This grouping of related pattern data points is known as clustering, and the process generates its labels.

4. Future of AI in Textiles

AI is still not widely used in textile technology. The sophistication, requirements for operating skills are the probable factors for the limited diffusion of such technologies. However, rigorous research and development are currently being carried out in numerous laboratories and technological companies to develop textile. In the future, AI will continue to be used to create new and innovative textile products. AI is already having a major impact on the textile as well as fashion and apparel industry is only going to become more important in the future.

-

Conclusion:

In this modern era, AI is being used in many areas to solve various problems with intelligence like human beings. Artificial intelligence is already proving to be extremely useful in the textile industry. Significant advancements are going on in this field and in near future it will become important tool for the processors, for enhancing quality, increasing production, lowering operating costs and exercising in-house control over production. To sum up, with the current technology, there is still room for optimization in the above steps of garment production automation. But this paper also has some limitations. Firstly, this paper only points out some theoretical feasibility, and does not verify the practical feasibility of these automation steps.