Importance of Agrotextile Testing & Testing facilities at COE-Agrotech

Dr. U.K. Gangopadhyay, Dr. Manisha Mathur and Mr. R. P. Singh, SASMIRA, SASMIRA Marg, Worli, Mumbai-400030

| Protected cultivation |

Now-a-days, we all are facing capricious weather conditions like high temperature in summer, unseasonal rain & hail, drought and excessive cold in winter etc. This is not the only problem, scarcity of the natural resources like land and water etc. are also aggravating the situation. Increasing population and urbanization has led to the encroachment upon agricultural land. Currently, the challenge is to produce more with less land and less resources. Traditional ways of farming are certainly not going to catch-up. Technologies are being explored to enhance Agricultural productivity and quality. Protected cultivation has the potential to isolate plants from external environment and establish plant desired microclimate, thus facilitates cultivation even in adverse climatic conditions. Agrotextiles like shade-net, mulch mat and crop cover etc. help in providing partial protected environment and have the potential to enhance Agricultural and Horticultural productivity.

| Agrotextiles |

Agrotextiles is amongst the front runners of the fastest growing Technical Textile Segments; these are used to support Agricultural/Horticultural activity. Agrotextiles like shade-net, mulch mat and crop cover etc. have the potential to mitigate the negative impacts of adverse climate. Growth rate of Agrotextiles along-with other segments of Technical Textiles is presented in the following table:

Table: Growth of Technical Textiles

Source: Technopack Study

| Potential for Agrotextile in India |

We are an Agriculture nation. Almost 60% of the population depends upon the agriculture for its livelihood. Gross Value Added by agriculture, forestry and fishing is estimated at Rs 18.53 trillion (US$ 271.00 billion) in FY18. There is a growing preference for horticulture crops amongst the Indian farmer because vegetables/fruits are short duration crops, these mostly grown on small patches of land by marginal farmers, often in less than an acre of land. As land holdings become increasingly fragmented, production of vegetables/fruits ensure quick returns to farmers, compared to agricultural crops like rice and pulse etc. which take relatively more time to harvest. However ever changing climatic conditions have a challenge that needs to be overcome to support our Agricultural as well as Horticultural etc. activity. Agrotextiles products have demonstrated not only improvement in terms of productivity and quality but also unseasonal cultivation. However, Agrotextile products are relatively new, nation-wide promotion of Agrotextiles on a mission mode is the need of the hour. Ministry of Textiles, Govt. of India has already given two pilot schemes

1- Promoting Usage of Agrotextiles in North East Region: Budget Outlay: Rs 55Cr (2013-2020)

2- Promoting Usage of Agrotextiles in Rest of India: Budget Outlay: Rs 10Cr (2015-2017)

Being Center of Excellence, SASMIRA has provided the technical support and field implementation of the schemes. The schemes have helped in spreading awareness about Agrotextile products. It has also catalyzed the growth of Agrotextile industry. Impact of the schemes has been summarized as under:

- Increased productivity : 2 to 5 times

- Avg. Increase in Farmer’s income: 67-75%

- Increase in intensity of crop: 3-4 crop cycles in a year & through-out the year cultivation

- Reduced water consumption: 30-45%

- Minimized use of fertilizers and pesticides: 25-30%

- Prevention of damages owing to birds: 100% protection and 20-30% increase in production

- Prevention of damages owing to hailstone: 100% protection

- Reduction in production loss owing to falling off of fruits: 20-30%

- Weed control and suppression: 100%

- Premium quality of produce

- Early and even ripening of produce (more harvest cycles per year)

India has 25.43 million Hectares practiced for horticultural activities, however only 1-2 % is practiced under protected cultivation. Promotion of Agrotextile will help in tapping the huge potential and improving socio-economic life of our farmers. Agrotextile & Allied industry will have to expand aggressively to meet this mammoth demand.

| Agrotextile products |

There are no. of Agrotextile products available, however each one of them sever two primary purposes

i)- Mitigate adverse climatic condition

ii)- Save/conserve natural resources. List of major agrotextile products and their basic function is given below.

The key functional properties required in agrotextile products are as follows:

- Weather resistance – They must work effectively in various climatic conditions involving wide ranging temperatures, precipitation, etc.

- Resistance to micro-organisms – They must be resistant to microorganisms to protect the produce and prevent diseases.

- Stable construction – The construction must be such that they can undergo a fair amount of wear and tear

- Light Weight – The weight of the fabric should be such that it can be borne by the plant

- Resistance to solar radiation. – They protect the plant from solar radiations

- Resistance to ultraviolet radiation – They must protect the plant/living being from ultra violet radiations

- Long service life – They ideally should have long life span

- Biodegradability – Agro textile products should be biodegradable after their life so that they do not pollute the soil and environment.

- Water conservation – They must have high potential to retain water and reduce evaporation

| Importance of Testing |

Technical textiles are meant to deliver specific performance. Meeting the expectation is of paramount importance. Ensuring performance characteristic of a technical textile product before putting it to use is essential. Hence it is very important to ensure quality of the material at every step right from raw material to intermediate to final product. Testing plays a vital role in conforming the quality of the raw-material and finished product quality for meeting the stringent quality requirements of a technical textile product. The materials used in particular may be in the form of fiber, yarn, fabric (woven, non-woven, knitted or braided) or in the form of composites. Agrotextile products are meant for outdoor application, therefore they have to survive the outdoor conditions. Hence, weather resistance in the context of Agrotextile is an indispensible characteristic. While some of the testing parameters to be evaluated for a particular product are similar to conventional textiles, a few specific test parameters have been devised keeping in view the performance or functional requirements of such product. Testing supports in following ways.

- Quality Control for products both during production and during installation

- Determination of the suitability of the material for the specific application / functional requirement

- Comparison between products for selection and

- Specification of a product for specific application

| Major testing facility at COE-Agrotech |

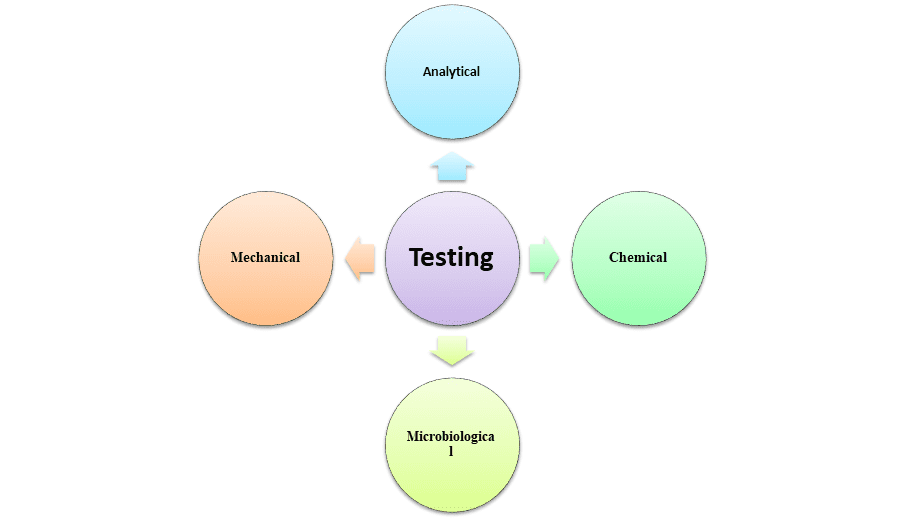

COE-Agrotech was established under Ministry of Textiles, GoI in the year 2008. It is equipped with state-of-the-art testing and product certification facility required for testing and performance evaluation of Technical Textiles particularly Agrotextiles. COE-Agrotech testing range can be classified in following four categories:

Testing facilities are accredited with National Accreditation Board for Testing and Calibration Laboratories (NABL) and American Association for Laboratory Accreditation (A2LA). There are no. of tests available for assessing the performance of different Agrotextile products; major tests have been summarized as under.

List of major tests

| 1- Simultaneous Gravimetric Analyzer (STA) |

The STA 6000 features the capability of simultaneous giving TG and DTA/DSC measurements. It serves the analysis of raw-materials as well as finished products to get insights of many important characteristics listed as under:

| 2- Scanning Electron Microscope (SEM) |

SEM is a versatile thermionic emission system intended for both high- and low-vacuum operations designed with respect to a wide range of SEM applications and needs in today’s research and industry. SEM is mainly used for surface analysis of the test substrate which is beyond visible light range, major applications are listed as under.

| 3. High Performance Thin Layer Chromatography (HPTLC) |

HPTLC (high-performance thin layer chromatography) is a sophisticated form of TLC, which provides superior separation efficiency. HPTLC system is mainly used for determining presence of targeted chemical component (in case of textiles banned amines or any other harmful substance) for its presence in textile substrate itself or finishing/coloring/coating material applied on the textile substrate.

| 4. High Performance Liquid Chromatography (HPLC) |

High-performance liquid chromatography is a technique in analytical chemistry used to separate, identify, and quantify each component in a mixture. Advantage of HPLC is that it allows HPLC allows quantitative separation of components in a sample. Target chemical component (in case of textiles banned amines or any other harmful substance) may be present in the textile substrate itself or into the finishing/coloring/coating material applied on the textile substrate. Available system is capable of determining both qualitative as well as quantitative analysis.

5. Gas Chromatography Mass Spectrometry (GC-MS)

GC/MS system is useful for analyzing presence of smaller and volatile molecules such as Phthalates, amines, benzenes, alcohols, aromatics, and simple molecules such as steroids, fatty acids, and hormones etc. It comprises of a gas chromatograph (GC) coupled to a mass spectrometer (MS), by which complex mixtures of chemicals are separated, identified and quantified. It can be applied towards the study of liquid, gaseous and solid samples

6. Fourier-transform infrared spectroscopy (FTIR)

Fourier-transform infrared spectroscopy (FTIR) is a technique used to obtain an infrared spectrum of absorption or emission of a solid, liquid or gas. An FTIR spectrometer simultaneously collects high-spectral-resolution data over a wide spectral range.

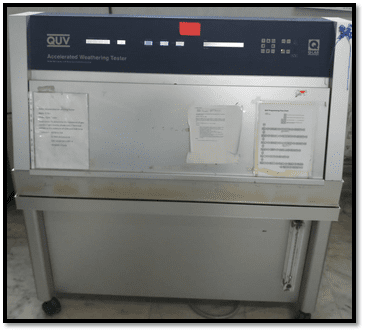

7. Accelerated Weatherometer

Textiles which are developed for outdoor application, needs to assessed for their weather resistance performance. Agrotextiles are meant for outdoor field application. In outdoor application product has to survive field conditions like UV, humidity and temperature etc. Hence it becomes important to have such tests which can predict product field life. QUV weathrometer facilitates such test.

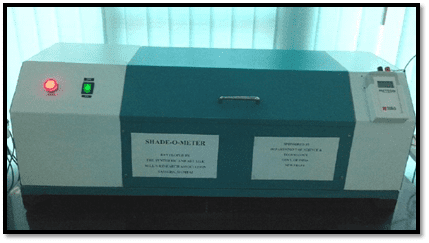

8. Shade-o-meter

For agricultural use, photosynthetically active radiation energy must reach to plants for optimum growing conditions so the measurement becomes necessary. Therefore, shading percentage becomes one of the important test parameter for agricultural net samples as it indicates the amount of light that is being transmitted through the shade nets. Before this equipment there was no equipment available to objectively test the shading percentage of shade-net fabric. SASMIRA developed this unique equipment which is quick and easy in operation. The equipment has been recommended by BIS for shade percentage testing as per standard IS: 16008 (part 1 & part 2)

| List of Standards for Agrotextile products |

We all know standards play a vital role in promotion and growth of a segment/industry. In the context of Agrotextile, in the year 2008 when COE-Agrotech was established by Ministry of Textiles, GoI, there was not even vocabulary for Agrotextiles was existing. COE-Agrotech has worked from scratch for development and promotion of Agrotextiles in India. So-far, COE-Agrotech along-with BIS has developed 12 IS standard for Agrotextiles listed as under: