Ladies and Gentlemen,

We appreciate your visit to the DiloGroup booth at ITMA 2019 in Barcelona. As at previous

ITMA exhibitions, DiloGroup is showing a fully functional needling line on a booth space of

ca. 1.150 m². This way, we want to highlight the importance of the European ITMA show in

regard to new developments and machines which represent the state of the art. It is also an indicator for the importance of needle felting technology as a whole which is, according to the annual production weight, the most important webforming and consolidation process for staple fibres. As a leading group of companies, Dilo emphasizes the central position this

technology takes in the worldwide nonwoven production. Needled products can be found in

many applications such as floor covering, automotive interior linings, technical needlefelts,

filtration media, geotextiles, mattress, bed and upholstery, wipes and papermachine felts.

Any type of fibre material can be processed, short or long staple, fineness from 1 up to

several hundred dtex and area weights from 30 g to several kg/m². This wide range of

parameters generates a great variety of products, a unique feature of needle felting

technology.

By large investments in research and development, DiloGroup contributes significantly to the exploitation of new applications based on increase in production capacity, improvement of quality features and increased efficiency in the production process. At ITMA in Barcelona we set a new focus on the further development alongside existing well-known technical

components. After ITMA these machines will be available in our Textile Research Centres for trials and demonstration.

High-Speed Crosslapper with Precision Laydown Technology

Hyperlayer HLSC 30/40 “NT”

The card is followed by the refined crosslapper HyperLayer “NT”, an example of high

speed, high precision crosslapping design. The precision of the laydown even at high speed

up to about 190 m/min. and a layering width of about 4 m makes this extraordinary machine

very suited for use in hydroentanglement lines. Currently there is no comparable

crosslapping technology which can achieve these values in regard to speed and precision

and also for viscose fibres. The Dilo crosslapper HyperLayer HLSC 30/40 will be installed

and available for trials in a hydroentanglement line in the new Textile Research Centre of

Messrs. Trützschler in Egelsbach after the show.

Compensation Apron FC-II

FC II and 3D-Lofter

A high speed crosslapper needs aprons to compensate for speed differences between cross

apron of the lapper and constant infeed of the needleloom. This high-frequency start-stopadjustment

is realized by our new “FC-II apron” with double arrangement.

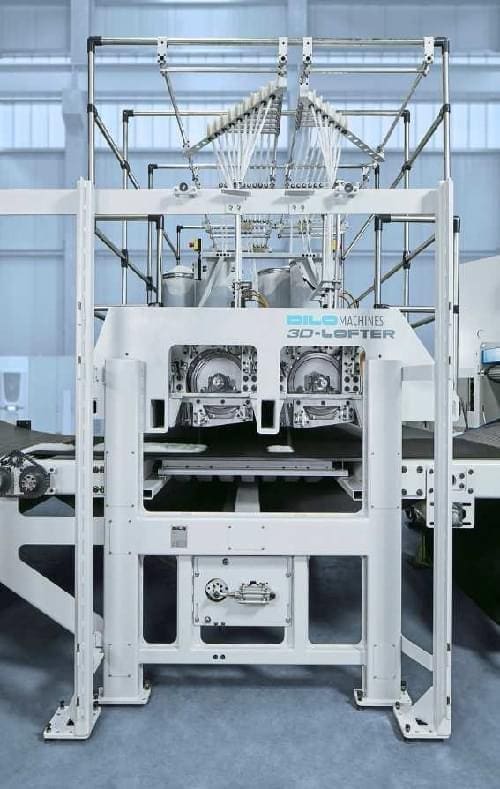

New Web Forming Technology – really innovative

The DILO 3D-Lofter

A series of individual web forming units which operate according to the aerodynamic web

forming principle shows how fibre masses can be placed with 3D topology on a base web so

that the correct amount of fibre is placed at the positions where in technical parts, such as

automotive, stretch and strain concentration can be expected. Thus thin areas following the

moulding process can be prevented and strain concentration in the force transmission area

can be balanced. This Dilo development is in conjunction with the research project

“optiformTex” of Chemnitz University, the STFI (Sächsisches Textilforschungs Institut

e.V.) and further companies including VW and Sachsenleinen.

This 3D-Lofter technology can also be used “inversely” to fill in thin areas in web mats before the card, especially when these are fed to “direct cards” without crosslapper or aerodynamic web forming unit. This improvement to the web mat leads to a more uniform fibre mass distribution in the web leaving the card or the airlay machine. According to theoretical considerations it is possible to increase the uniformity by about 40 %. The study is continued under the name “IsoFeed” in the enlarged Textile Research Centre of DiloGroup in Eberbach.

Another possible application of this 3D-Lofter technology could be in extended colour

patterning of floor coverings, in the mattress and bed industry, in apparel and shoe

production. This innovation opens a wide potential of web forming possibilities by “additive

textile manufacturing”.

Hyperpunch – Progress for Better Economy and Higher Stitch Distribution Uniformity

DI-LOOM HαV Hyperpunch

A new and more simple realization of the kinematic needle beam movement for reducing

detrimental draft and increasing the throughput speed makes the current elaborate

Hyperpunch technology also interesting for universal use.

Revolutionary Needle Patterns

Stitching plate “6000X”

The combination of Hyperpunch with the new needle pattern “6000X” results in a more

uniform stitch distribution at preneedling. In a complete needle felting line this effect of more

evenness can be further improved by using the new needle pattern “8000X” which can be

considered as a breakthrough for a considerably improved stitch distribution evenness.

Especially when producing flat needle felts which are used as decorative material in the

automotive interior, this great advantage will be evident. The DI-LOOM HαV Hyperpunch

needle loom will also be available for demonstration in our Textile Research Centre after the

show.

Diloline 4.0 – Internet of Things

DiloGroup will show at ITMA 2019 several development modules to illustrate the future

potential degree of automization in nonwoven production. The I4.0 modules are meant to

facilitate operation and to improve data transparency in production, operation control, quality

and maintenance. The solutions offered by DILO, “Bale Timer”, “Smart Start” for a fully

automatic starting aid or “DI-LOWATT” for energy savings, are supplemented by Siemens

based solutions which can be chosen via app and data Cloud “MindSphere”.

Please see the attached brochure for more information.

We would be pleased to welcome you in the near future to our new Textile Research Centre

in Eberbach, Germany. This facility is being enlarged by 800 m² to a space of ca. 3000 m²

and will include all the machinery on display in Barcelona.

DiloGroup appreciates your interest and wishes you a worthwhile visit to the exhibition.

Yours sincerely,

J. P. Dilo