Biomedical engineer and an early additive technology proponent, Brian McLaughlin is passionate about the potential of electron beam melting (EBM) for orthopedics implants. His company Amplify Additive has quickly become a leader in the market thanks to a combination of deep clinical knowledge, engineering design expertise and over two decades additive manufacturing experience.

Within the medical industry, the orthopedic sector continues to rapidly adopt additive technologies. Industry analyst SmarTech estimates that the orthopedic segment of the additive manufacturing market generated almost USD$200 million in 2016 and is forecast to grow by around 30% CAGR until at least the middle of this decade.

Additive is expected to play a growing role in the ongoing evolution of more personalized and bespoke medical treatment. Today, it is used for a wide range of orthopedic implants and is helping designers and specialists reimagine medical instruments and equipment.

The bridge between surgeon and engineer

McLaughlin is passionate about this pathway to patient-centric solutions. He and his team are able to apply a combination of deep clinical knowledge and more than twenty years working with additive technology.

“We often to act as the bridge between two very different disciplines – orthopedic surgeons and design engineers. Teams often have a shared vision, but uncertainty about how best to implement additive can sometimes present hurdles to overcome. We’re able to use that combination to add value and offer organizations solutions to overcome those hurdles – because we implicitly understand both sides of the conversation,” said McLaughlin.

McLaughlin is equally passionate about continuing to educate the orthopedic community the potential for additive, everything from the choice of materials, technology modalities and design freedom.

“The orthopedic community is a beacon for using additive manufacturing to drive innovation be that conceptual applications all the way through the volume production of implants. Continued education and knowledge sharing will only empower surgeons and engineers to push boundaries further,” he added.

Scaling Operations with EBM

McLaughlin formed Amplify Additive in 2018 to help customers in the orthopedic sector leverage additive within their organisations. Today, the Amplify team advises predominantly customers in the medical sector on design for additive, time to market and supply chain strategies.

In September 2019, McLaughlin opened Amplify’s first facility in Scarborough, Maine. Since the decision to locate in Maine, the question has come up as to why. McLaughlin’s response, “Why not! We are as accessible, if not more accessible than other additive manufacturing groups, with Portland international airport just a few minutes from our front door. The team is also working with the University of Maine’s Center of Additive Manufacturing of Metals (CAMM) on a number of veterinary applications.”

“Many organizations still lack infrastructure in-house – be that the design experience, or additive machines,” said McLaughlin. “The reality is however that any company can buy a machine, but the question remains – do they really know how to operate it and deliver end-use products with it. This business is all about having the right people who understand the applications and the technology, we have both, and have in fact done this before.”

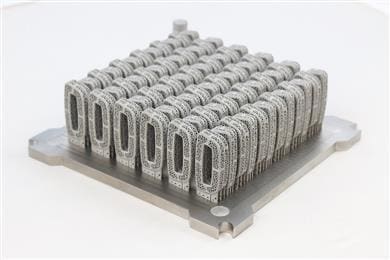

“I’m 100% behind EBM, and I believe the industry is in desperate need of additional capacity – specifically for the medical sector. The design freedom, flexibility and ability to stack efficiently on the build plate make EBM perfectly-suited for the manufacture of orthopedic implants. And with more surface roughness it could ultimately provide a better clinical environment for bone attachment and ingrowth,” he added.

The modern facility features three GE Additive Arcam EBM Q10plus machines as a cornerstone of its operations – which has a modular infrastructure to flexibly accommodate anticipated growth. McLauglin and team plan to scale the business quickly and have recently been recommended for ISO 13485:2016 after only seven months at their new facility. With future plans to extend their capabilities to the aerospace market, for now the team at Amplify is 100% focused on the medical sector.

Additive sits in a place in the market where it is able to accelerate product development and manufacturing for companies who current use and have always wanted to use additive manufacturing for their implant solutions. It is Amplify’s goal to be an orthopedic center of excellence for additive manufacturing in the US, and eventually worldwide.