NURHANNA SAFWA BINTI MOHAMMAD BACHTIAR

What is functional clothing? According to TECHUNTER Media, functional clothing is clothing with the purpose to satisfy the need for functionality and adaptivity to certain conditions. Previously, only people who partake in active activities had the privilege of wearing it but now with recent developments, all borders are erased and available even in daily wear.

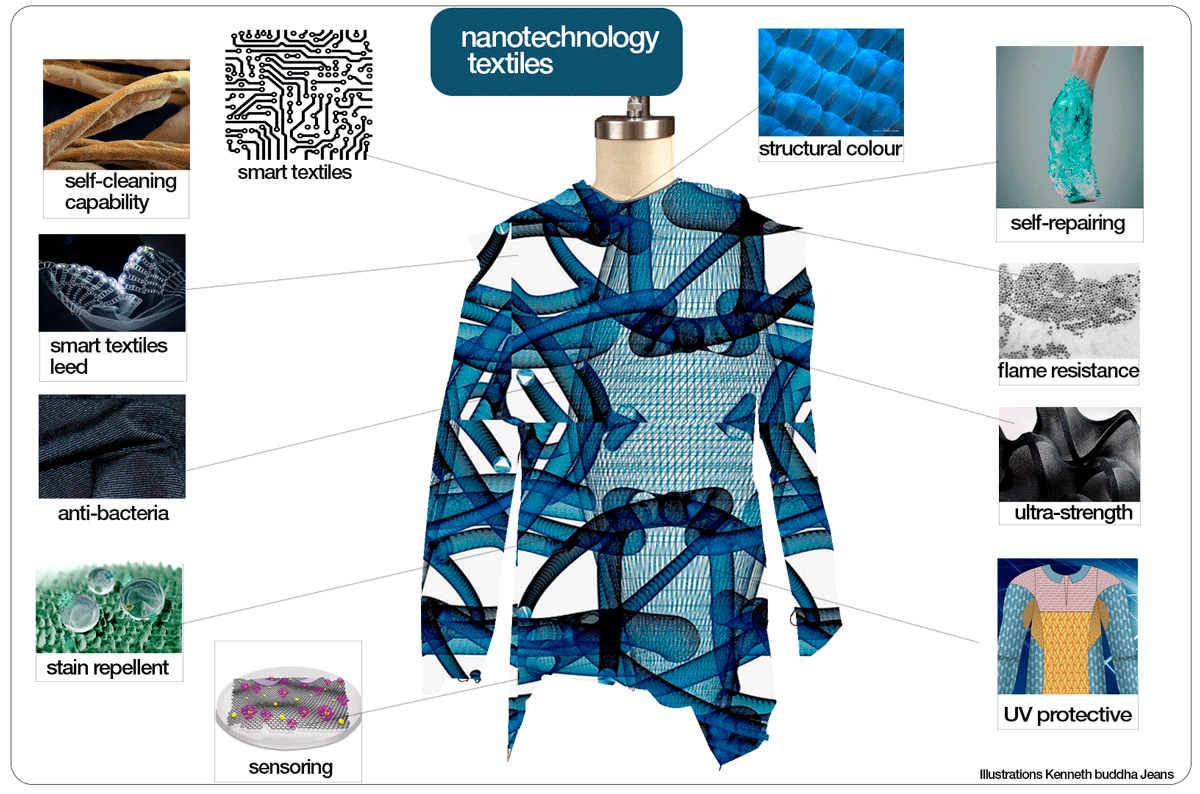

Generally speaking, there are multiple ways to functionalize clothing, most commonly used industrially is by applying a functional finish to the cloth itself. Finishing is an important process when producing fabric. While some textile finishes have been applied by altering the fiber properties, some finished have been coated onto the ready-to-wear garments. While both processes have been done according to the demand, it contributes greatly to the characteristics and provides additional functionality to the fabric. With the textile industry having many developments over the years, the finishing process now has a wide range of technologies and techniques to be chosen from. One of the most useful textile finishing is including nanotechnology finishes.

Figure 1 shows Water Repellent technology in Textile offered by NanoTextile Sdn Bhd

What is the type of textile finishes and how it works?

- Temporary finish

The textile is commonly treated with a paste comprised of starches and gum, filling materials, softening agents, wetting agents, glazing agents and more. The finishing will not stay on after several times of washing.

- Semi-durable finish

This type of finishing is usually done by applying a finishing coat to the fabric and its lifespan depends on the types of finishes used on the fabric. Last longer than temporary finishing. Types of semi-durable finishes are soil release and mothproof.

- Permanent finish

Usually done by modifying the fibre properties minimizing the fabric flaws. Able to last a long time and withstand longer washing cycles. Most common permanent finishes are anti-shrink, flame resistant and water repellent.

Figure 2 shows functionalized fabric with electrical components (smart textile)

Other than in the finishing stage, clothing can also be functionalized with the help of electrical components whereby nowadays people called it as Smart Textile. Innovation in smart textiles has made it possible to weave tiny electrical components such as a sensor to detect the body temperature or movement to blend seamlessly into the fabric construction. Also with conductive yarn, metals such as copper and titanium can be coated or blended into the yarn itself making it able to conduct electricity.

How do fashion brands perceive technology in fashion?

According to CBINSIGHTS on the future of fashion, fashion companies are now beginning to partner up with technology providers, snapping up start-ups and building their technology to seize the opportunity to open more revenue streams and business models. With the help of big fashion brands such as Uniqlo, it does help in accelerating the public acceptance of technology in fashion. Uniqlo offered functional clothing including the HEATTECH collection which retains heat to keep the users warm during cold conditions, AIRism technology; which actively wicks away moisture and heat from the skin, and not to forget, their UV Protection clothing. Some fashion brands in Malaysia specifically in the Muslimah segment have also slowly added nanotechnology finishes into their products line, for instance, dUCk, Inner Sejuk, Alhumaira, Tudung People, Telekung Siti Khadijah, CalaQisya, Olloum and Naelofar.

This is an advantageous development for companies such as NanoTextile Sdn Bhd, the 1st and only textile technology service provider company in Malaysia. NanoTextile specialises in supplying nanotechnologies to textiles and ready-to-wear clothing. With their range of technology series such as the Hygienic, Protection, Comfort, Care, Premium and Advanced series, it’s a no-brainer that they managed to collaborate with a few famous name brands such as PONEY, Polo Haus, Volvo Car Malaysia and a few famed Muslimah brands in Malaysia. One of their well-known series is Hygienic Series which consists of Antibacterial, Odour Control and Self-Cleaning technologies. Moreover, the nanotechnology embedment processes done by NanoTextile are able to provide a greener technology to help with the long-overdue issues about the fashion industry’s environmental and social impact.

When it comes to production especially in the textile segment, the crucial part that has been highlighted in the process is sustainability. From manufacturing, design, materials, processing, chemistry and packaging, NanoTextile has been taking part in two main processes which are manufacturing and chemistry. Both played such an important role, for instance, the solution that has been used is water-based which compliant to the RoHS Compliant hence it is zero-toxicity. In terms of manufacturing, NanoTextile has been operated by using 40.5% of solar power plus no plastic packaging has been used, instead, it has been replaced by reusable storage box.

In conclusion, development in the textile and fashion industry is important for fashion growth. Technology does not only help in fashion growth, but its presence has been improving the value of sustainability in textile segment. The most important part is choosing the right technology with no effects on the body and the environment. From providers to consumers, we are all benefiting from technology to enhance our daily life and improve the environment.