Freudenberg Performance Materials is expanding its production capacity for nonwoven media used exclusively to manufacture certified face masks of the mouth-nose protection type pursuant to the EN14683 standard, as well as FFP1, 2, and 3 masks pursuant to the EN149 standard. The company is a leading global supplier of innovative technical textiles.

The media are specially developed for and sold to the medical technology processing industry. To that end, Freudenberg is investing in the construction of a new state-of-the-art melt-blown production line at the Kaiserslautern site. Commissioning of the new plant is slated for the first quarter of 2021, the company said in a media statement.

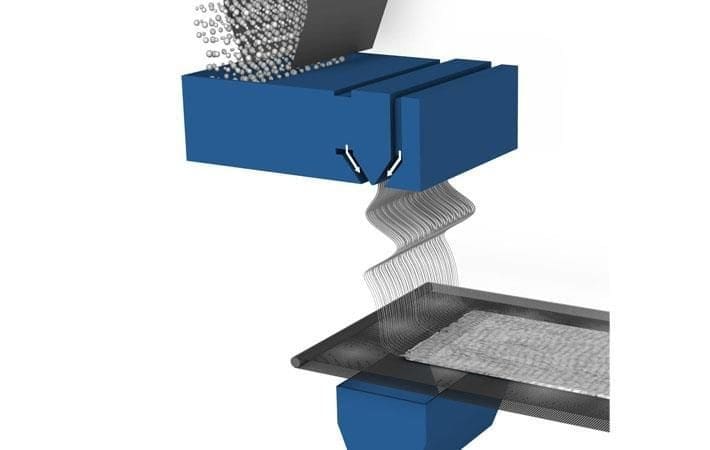

With the new line, Freudenberg is significantly expanding production capacity for melt-blown nonwovens in Kaiserslautern. The world-leading technical textiles manufacturer produces these materials from extremely fine melt-spun polypropylene microfibers that are several times thinner than a human hair. Masks made of these nonwovens can filter very small particles such as viruses thanks to the superfine structure of the material and its electrostatic charge.

“As a world-leading manufacturer of technical textiles and filtration media, Freudenberg Performance Materials has deep expertise in materials for certified face masks. By expanding our production capacity in Kaiserslautern, we are making a contribution to mastering the challenges presented by COVID-19 and supplying certified type face masks as well as FFP1, FFP2 and FFP3 masks in Germany and Europe”, the CEO of Freudenberg Performance Materials, Frank Heislitz said.