Global Nylon Yarn Market: Overview

Yarn can be produced naturally by the medium of plants, insects, and animals or synthesized artificially. It is a continuous assembly of fibers and signifies a core ingredient in the textile industry. Yarns can be characterized based on physical structure and performance. Synthetic yarns are widely used for commercial purposes owing to their high tenacity and resilient characteristics. Nylon yarn is a synthetic material yarn that resembles the appearance and texture of various natural fibers. Nylon yarns are strong, flexible, and generally cheaper than natural fiber yarns. Nylon is transformed into monofilament, multifilament, or microfilament yarns. These yarns possess high stretch recovery, excellent impact strength, good thermal conduction, high-temperature resistance, high chemical resistance, and highly durable properties. Nylon yarns are used for various applications; in terms of value, lower-range nylon yarns are used in the manufacture of garments, while higher-end nylon yarns are employed in industrial applications.

Global Nylon Yarn Market: Drivers & Restraints

The global nylon yarn market is primarily driven by the increase in demand for these yarns in the textile industry. Nylon yarns are used in industrial brushes, as they provide good fatigue and abrasion resistance. These yarns are used in zip fasteners because of their abrasion resistance and low coefficient of friction. An increase in the utilization of nylon yarns in the manufacturing industry owing to their exceptional properties is anticipated to drive the global nylon yarn market. Nylon yarns are non-toxic and non-allergenic and are extremely resistant to mold, bacteria, and insects. The rise in demand for nylon yarns in the medical industry is anticipated to boost the global nylon yarn market. Advancement in material and chemical properties of nylon yarn in order to make it multifunctional is expected to offer lucrative opportunities to the global nylon yarn market during the forecast period.

Global Nylon Yarn Market: Key Segments

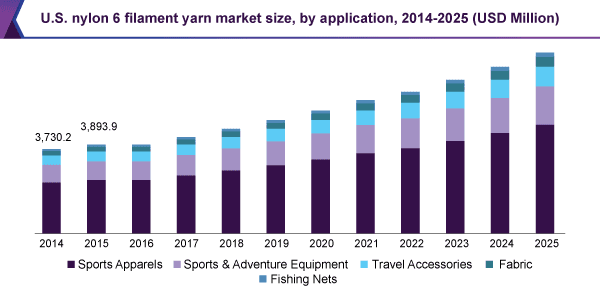

Based on type, the nylon yarn market can be segmented into nylon 6, nylon 66, and others. The nylon 66 segment held a key share of the global nylon yarn market in 2017. Nylon 66 exhibits higher wear & tear resistance, feather-light property, and extreme dimensional stability. Thus, they are used in versatile applications such as clothing, furnishings, or industrial fabrics.

In terms of grade, the nylon yarn market can be divided into FDY (full drawn yarn), DTY (drawn textured yarn), POY (partially oriented yarn), nylon chips, and others. FDY, DTY, POY, and nylon chips are techniques used to produce nylon yarns. POY is used for air-texturizing/ draw texturizing applications, while FOY is employed for twisting and weaving applications.

Based on application, the nylon yarn market can be segregated into sportswear and sports equipment, hosiery and apparel, medical textile, industrial applications, and others. Hosiery and apparel accounted for a major share of the global nylon yarn market in 2017. Nylon yarns are primarily employed in the manufacture of fishing nets, fishing ropes, fishing tugs, sports nets, gutting for sports rackets, industrial filter cloth, tarpaulin cloth, conveyer cloth, bristles for shaving brush & toothbrush, industrial brushes, clothing stiffeners, wigs, surgical sutures, zip fasteners, sewing thread, ropes & twins, etc.

Global Nylon Yarn Market: Regional Outlook

In terms of geography, the nylon yarn market can be split into North America, Latin America, Asia Pacific, Europe, and Middle East & Africa. The Asia Pacific constitutes a substantial share of the global nylon yarn market due to the easy availability of raw materials at competitive prices in the region. Rapid industrialization in developing economies such as China and India is projected to propel the demand for nylon yarns in the near future. North America and Europe are prominent consumers of nylon yarns.

Global Nylon Yarn Market: Key Players

Key players operating in the global nylon yarn market include Fulgar SpA, KOLON INDUSTRIES, INC., JCT Limited, Zimmer AG, SRF, SUNTEX FIBER CO., LTD, Acelon Chemicals & Fiber Corp, Century Enka, TORAY INDUSTRIES, INC., and W. Barnet GmbH & Co.