Researchers from British Columbia, in their recent article published in the journal Cleaner Engineering and Technology, have not only studied and suggested various novel strategies for utilization of textile waste but also thoroughly evaluated its effectiveness and viability.

Global Textile Industry and Global Pollution

Fabrics and garments are among humanity’s essentials, and the global textile industry has been giving the topmost priority to its customers since its inception. However, with the fast rise and change of clothing styles over the past decades, textile production and trash creation rates have skyrocketed. The textile sector is the world’s second-largest economic contaminant, responsible for 10% of worldwide greenhouse gas emissions and 20% of worldwide wastewater.

Fibrous debris and scrubbed substances dominate fabric by-products created throughout the energy-intensive manufacturing procedures of new apparel. This compact fiber trash is made up of a variety of organic and inorganic polymer composites, including cotton, polyester, polyethylene, and others.

A major source of worry is the substantial environmental contamination produced by increasing volumes of old clothes in municipal solid waste (MSW) landfills, which are disposed of by garment customers and fashion businesses. Textile waste amounted to 5.8 percent of total dumping sites MSW, according to the US Environmental Protection Agency (USEPA) (2018).

Pollution in Construction and geotechnical industries

Construction and geotechnical engineering are also widely recognized as utilizing a massive quantity of natural resources. As a result, this article examines the physical, chemical, and toxic qualities of a variety of natural and manufactured waste fibers to establish their suitability as carbon fiber for architectural and geological reasons, to assist in lessening the pressure for scarce water resources.

The paper in the journal Cleaner Engineering and Technology addresses two major issues related to the sustainable utilization of recyclable materials and provides a stockpile of the field’s viable implementations of textile fiber refuse in terms of economic growth, atmosphere, and achievement, as landfills have long-term environmental consequences.

Each stage of the textile production and processing cycle produces a vast amount of effluent, which has a significant harmful effect on the environment. During the de-sizing and whitening process, high biological oxygen demands (BOD) and hazardous chlorinated by-products are created.

Importance of Natural Fibres

Natural fibers come in a wide range of colors and textures. Designers in many impoverished countries have used natural fibers for soil reinforcement due to their advantages such as low cost and convenience. Natural fibers commonly utilized for soil enhancement include palm coconut husk, sisal, jute, wheat hay, and areca. By altering the fiber quantity and fiber length, the composite’s strength and stiffness may be adjusted.

As natural fibers are hydrophilic, their potential to absorb moisture is an issue. Because of the surrounding water between the fibers, a hydrodynamic tension force links them, and when it dries, each fiber is attached by adhesion forces. This effect will continue as long as capillary water exists between the fibers.

Importance of Synthetic Fibres

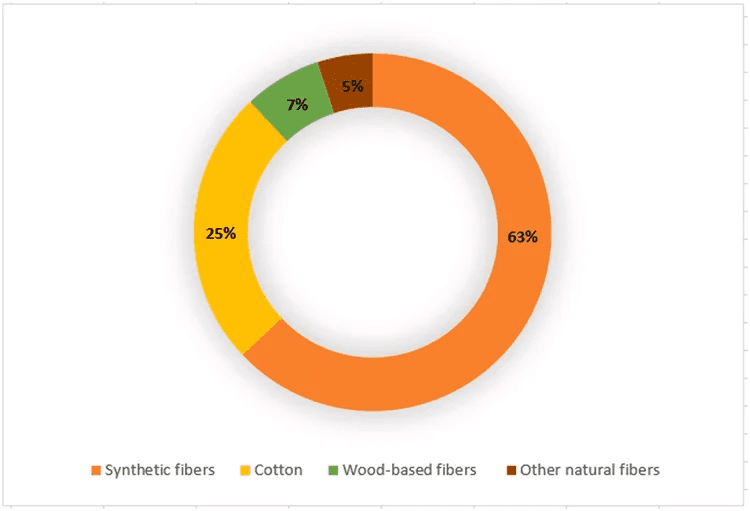

Artificial or man-made polymers have absorbed a portion of the total textile business in recent decades. Petroleum is the primary raw material utilized in the production of polymeric materials; polyethylene, polyester, and nylon are some of the most widely manufactured synthetic fibers in the industry.

The non-biodegradability of polymeric materials creates a technical and energy problem in the constraint of landfill dumping. However, because synthetic fibers are also homogeneous, they are an excellent choice for manufactured composites. The uniformity of the fiber type facilitates the performance of numerical simulations.

Applications of Textile Waste in Construction and Geotechnical Engineering

To address the unsustainable methodology of massive waste output from the fast-developing sector, sustainability technologies influence environmental, economics, and effectiveness must be offered. Textile waste fiber has potential uses in architecture and highway construction, including the development of sustainable acoustic and thermal insulation, novel cement (such as polymer concrete) or plastering cement, asphalt masonry, cement composites fabrication, and so on.

Modification of the subgrade layer, stability of the constructed slope and compressed earth, and enhancing the physical qualities of constructed backfill are some of the key applications of textile fiber usage in geotechnics.

Applications in Soil Stabilization

One of the earliest and most well-established applications of discarded synthetic fibers is the technique of enhancing the mechanical characteristics of soil by including discrete fibers as reinforcing structural components. It is often regarded as a more effective substitute for traditional soil stabilization approaches that rely on adherent clay soils, rock, Cementitious materials, and lime. In conclusion, textile waste has great potential for utilization in the fields of civil engineering and geosciences.