Ahmedabad – From 8th to 13th December 2022, India’s largest textile machinery show ITME was held in Greater Noida, India. Stovec, a subsidiary of SPGPrints BV, The Netherlands, announced a successful show by introducing the latest innovations in both conventional and digital textile printing for the fashion and the home-furnishing industry. As the inventor of rotary screen technology in 1963 and the initiator of digital textile printing in 1991, SPGPrints has been playing a leading role in textile printing for over 60 years now.

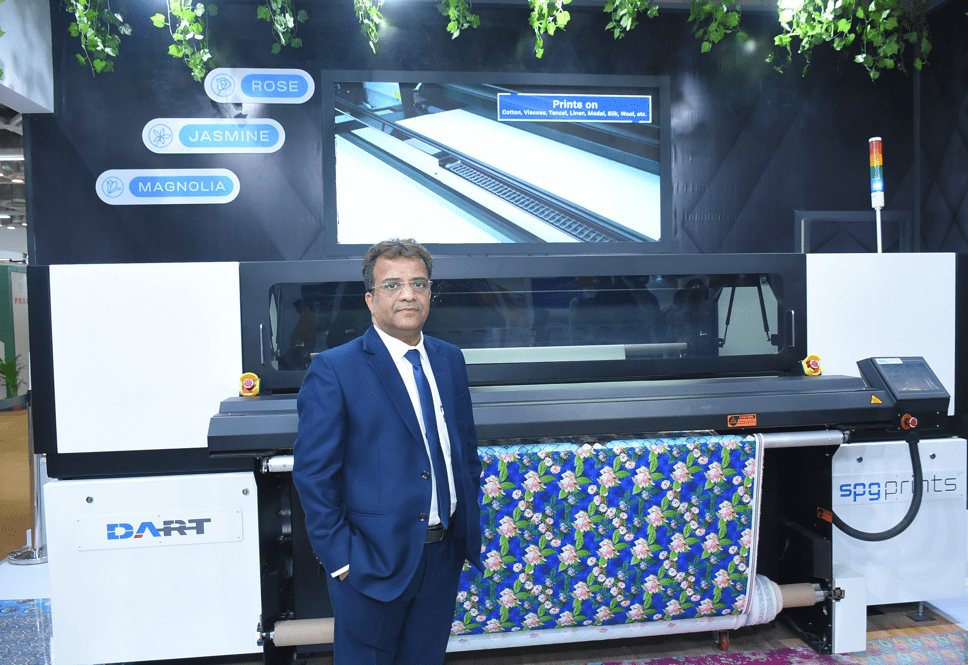

Mr Shailesh Wani (Managing Director, Stovec Industries Ltd.)

Our global brand ambition with focus on sustainability unveiled

At ITME, SPGPrints proudly presented its global brand ambition with new slogan “Printing tomorrow.” to its customers worldwide. With this, SPGPrints highlights its ambition to be the reliable partner in the global textile and industrial printing market while taking care of our planet in a responsible way. Looking for a conventional or digital textile printing system, SPGPrints has always proven to be the total solution provider for all textile printing needs.

SPGPrints|Stovec booth at India ITME, Dec’22

World premiere of entry level digital printer DART with live demonstrations

SPGPrints launched the new robust entry level digital printer – DART at ITME for its Indian customers who want to kick start their journey in digital textile printing. The ribbon cutting ceremony was done by two proud DART customers – Mr Akash Sharma (from Akash Fashions, Ahmedabad) & Mr Parthiban M (from Brindhaa Processing Mills, Tirupur).

Supported by live demo sessions every hour, while also printing the varied customized needs of visitors on site, DART proved to be a perfect solution for start-ups to fulfill their need for a medium speed printer. With fast turnarounds and full application support, DART gained immense customer’s attraction during the show.

The digital technology of this digital printer enables customers to print on demand at a top quality of 720 x 1080 dpi, using 8 colours. With an extra row of print heads, amounting to 16 print heads, it can print up to 150 square meters per hour in fast mode. The optimum drop size helps to produce clear images, vibrant colours and smooth gradations. The installation is plug & play and the latest colour management engine and colour processing tools are included in the preloaded RIP software. The machine is designed for continuous production, that offers immense creative opportunities to customers to print on even the most difficult fabrics.

Launch of digital textile printer – DART

Rose, Jasmine, and Magnolia: three new digital printers

SPGPrints|Stovec also introduced the addition of 3 new digital printers in the portfolio – Rose, Jasmine, and Magnolia, that focused on maximum productivity at optimal print resolution.

Rose is a roll-to-roll paper sublimation system with a peak productivity of up to 720 sqm/h. With variable ink drop-size and a maximum resolution of 1200dpi, the print quality offered is excellent.

Jasmine and Magnolia are direct to fabric systems that will enable our customers to extend their offering in digital printing. Jasmine focuses on maximum productivity at the most optimal print resolution where Magnolia with its true 1200 dpi and Archer+ technology raises the bar to new levels of print quality.’

Introduction of Teak, our latest innovation in Rotary Textile Printing

Through the years, our industrial roots have proven to be a solid platform for countless inspired innovations, that have put SPGPrints on the map as a global market leader for textile rotary screen printing technology. The company was proud to showcase our latest innovation in rotary portfolio Teak, a 2.45 meters wide rotary printing machine with Universal Repeat functionality. Teak is the latest generation of the Pegasus series, that has opened a wide-spectrum of applications for our customers worldwide, allowing them to print on woven and knitted fabrics for fashion and home textiles. All repeat sizes from 640 to 1018 mm can be printed in the same machine without any modification of parts.

What is also unique to the Teak is that both squeegee types can be combined in a single position. This gives the utmost printing flexibility, and is ideal for optimising effects such as half tones, fine lines and blotches.

Introduction of TEAK machine with universal repeat functionality

The evolution of rotary screen technology

With the introduction of two the new screen types Ortascreen and Randomscreen Eco together with rotary printing machine Teak and the latest BestLEN engraving technology, SPGPrints underlined its statement to the industry that the rotary printing market is still growing. The visitors could see print samples available at booth, made with OrtaScreen, a revolutionary screen based on the flatbed screen structure. The latest-paste saving screen RandomEco, that also helps to avoid Moiré, was also shown on the booth.

N▸RICH technology: better inks for a better planet

‘Based on our know-how plus 30 years’ experience in ink development, SPGPrints inks offer optimal colour efficiency. They are made with the best available dyes and chemicals. For us quality has always been key, but sustainability is now even more important than ever. When selecting ink components, we consider all known and expected RSLs (restricted substance lists) for all major brands and meet guidelines such as REACH, OEKO-TEX® and ZDHC. We apply N▸RICH technology to develop and produce our benchmark quality digital printing inks for textiles in a sustainable way.’ says Daan de Kubber, Innovation & Development Manager at SPGPrints Boxmeer, The Netherlands. ‘We have created three different performance levels for our most used inks that you can mix and match to suit your digital textile printing applications: Pasha, Morpho and Alcon series. These are compatible with all major industrial print heads and fabrics. Our inks guarantee unattended

printing without nozzle blockages or print head failures while adhering to the highest standards and legislation on sustainability’.

Commercial success

During the show SPGPrints signed contracts for several rotary printing machines, engraving systems, digital printers and also received highly potential enquiries for rotary screens and digital inks. This has made the ITME 2022 one of the most successful events in the recent history of SPGPrints, and also empowers us in creating a path to a sustainable future for our customers.