Webinar on “Textile Wet process Optimization and Management Strategies and Cost-Neutral Techniques”

“Textile Wet Process Optimization and Management Strategies and Cost-Neutral Techniques” This Webinar was held on 26th November 2021 5.30 PM IST onwards through Online Live MS Teams. It involved an elaborate discussion on the most industry-relevant theme of sustainability in textile wet processing, optimization and management. The program began with a warm welcome to the panelists and to the esteemed audience for the event that was expressed by Dr Vishaka Karnad Honorary Secretary, SDC EC. The discussion amongst the panelists was very well moderated by MR. ULLHAS NIMKAR (M.SC. LEEDS – UK, C.COL, FSDC, FTA) (PRESIDENT ELECT SDC UK & CHAIRMAN & MANAGING DIRECTOR, NIMKARTEK TECHNICAL SERVICES PVT. LTD.) His words that were filled with positivity set the direction for the interactive discussion. The deliberation was on sustainability as the key function of textile wet process optimization and management. It highlighted how companies are and must be geared towards making the textile wet processing industry clean. The points for discussion were clearly laid down for the panellists to individually pick on and explain the strategies and techniques that they adopted to make textile wet-processing sustainable representing their companies.

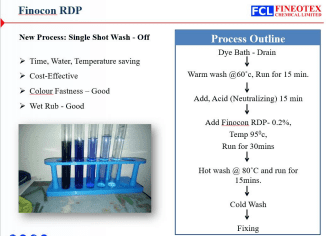

Panellist 1 : MR. ARINDAM CHOUDHURI (CEO, FINEOTEX CHEMICAL LTD.) elaborated on the process optimization techniques and products that the Fineotex Chemical Pvt. Ltd. deals with. Some thoughts for introspection included “Let’s Make Sustainable Fabric For Human Without Affecting Nature, Yes we can Save … if we Try to be Sensible, Control Waste… Live & Let Live… Save Oil… Shut down Engine at Signal. Reduce Pollution, Are we heading to achieve ZLD or water harvesting or re-cycling of sewerage water ? Can we reduce the sludge percentage after ETP, or can we reduce the inorganic chemical use in the process… concentrated chemical use to reduce petrochemical base packing material and air pollution while transporting the chemicals, etc.”

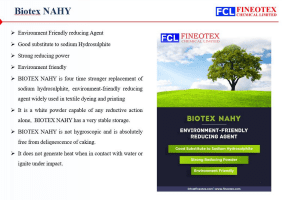

Extensive description and analysis were projected for Fineotex India and Biotex Malaysia, . certifications of the company products included Bluesign, OEKO – TEX ECO PASSPORT, GOTS, various company products and their features were presented.

A noteworthy product information that was shared included Biotex NAHY that is an environment-friendly reducing agent.

Panellist 2: DR. SWAPNESHU BASER (MANAGING DIRECTOR, DEVEN SUPERCRITICALS PVT. LTD.) explained the waterless technology using supercritical processes. The presentation highlighted the advantages and the challenges faced in using supercritical technology.

The deep problem of excessive use of water in the textile wet processing industry was emphasized and how to use supercritical fluids as a replacement for water as solvent in dyeing process was elaborately explained. Carbon Dioxide (CO2) has emerged as the most preferred supercritical solvent. Advantages of supercritical CO2 process include faster dye diffusion and penetration in the textile, significantly shorter dyeing and processing times, CO2 is nonexplosive, generally regarded as safe, SC CO2 is inert: there is no damage of the fibre or fabric and is a zero-discharge process.

The technology includes that prior-art SC CO2 process use special dyes, dye is first dissolved in SC CO2 and then transported to the fabric in dyeing vessel, dyes have low solubility in SC CO2 resulting in low dye concentration in the dye solution, in the dyeing vessel some dissolved dye may not come in contact with the textile surface, non-uniform flow / channelling of SC CO2 solution through textiles in the dyeing vessel lead to non-uniform dyeing, final shade of dyed textile depends on time and extent of exposure : batch to batch variation, this technology is mainly useful for applying dark shades and only single colour at a time, the limitations listed above make conventional/prior art SC CO2 dyeing process less versatile, slow and less efficient. This brings to forefront the requirement for further research in these directions. The details of the patented technology were shared during the webinar.

Panellist 3: MR. IAN SMITH (CTEXT FTI) (CONSULTANT AND BUSINESS DEVELOPMENT TEXTILE CONSULT LTD. UK) described what is the importance of sustainability relevant to current textile scenario elaborating on the ways and means to make textile processing environment-friendly.

Some of the points highlighted in the presentation and ensuing discussion included:

- Escalating costs relating to water usage and effluent treatment to meet regulations have been a concern for many years.

- More stringent legislation relating to effluent quality, e.g., toxicity, colour (some water companies have already introduced colour charges, and this trend could increase)

- Rising water supply costs as water companies invest in improved distribution systems to reduce leakage, new treatment plants to improve water quality and new water supplies to meet increased demand.

- The industry on a global scale went through a time where factories built larger and larger effluent treatment plants (ETP) were built, these ETP’s did nothing to optimize the process or reduce the environmental impact of textiles they just dealt in some part with what was been produced and this meant that the industry stagnated, and developments were stalled.

- The industry needed and, in some cases, still needs to find a new way of thinking. Sustainability / optimization should not be a business opportunity, for consultants, it should be an industry mindset, sadly too many times this is not the case.

- Textile Wet Process Optimization and Management requires understanding the actual situation, the general process flow, woven and knit fabric finishing, stock and yarn dyeing finishing that were briefly covered.

- Process modification and chemical substitution methods were briefly described and simple options for chemical reduction were proposed. Chemical recovery and reuse techniques were shared.

- Impact of automation and its influence and developing technologies were enlisted and briefly explained.

The program received good online participation including textile wet processing industry personnel, academicians and students. The discussion was interactive engaging Q&A towards the end thereby leading to greater information sharing. The feedback link and certificates were issued to the enthusiastic participants. A hearty vote of thanks was offered by Mr. Sandeep Singh (Hon. Trustee Member SDC EC).

It was a grand success owing to the generous sponsorship rendered by Fineotex Chemical Pvt. Ltd. without whose support the event would not have taken shape. Also, gratitude is expressed for the backend work and coordination by Mr. Sandeep Singh (Hon. Trustee Member SDC EC), Mr. Jayram Gugale (Coordinating Office Staff) and to all the members of the Trustee Board Members of SDC EC. We look forward to organizing more events in future in order to fulfil our mission of knowledge dissemination and networking.

On behalf of the SDC EC

-Dr. Vishaka Karnad

Honorary Secretary SDC EC

EVENT SPONSOR