IACC Textile Forum in association with US Commercial Service, US Consulate hosted Conference on Textiles “America First & Make in India: Achieving USD 100 Billion Trade in Textiles” held 24th April, 2019 at Hotel Taj Mahal Palace, Mumbai.

The objective of the Conference was to create, develop & sustain successful bilateral partnership in textiles between USA & India. This would necessitate in increasing the scope for trade and promotion of niche sectors in textiles such as apparels and home textiles.

The conference saw participation of more than 250 delegates from the leading textile industries. Inaugural Function started with the lightening of the Lamp by Chief Guest and dignitaries.

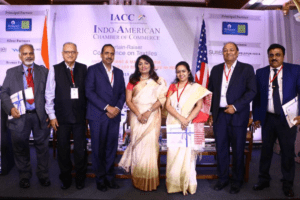

The event was inaugurated by Mr. S. K. Sarkar, National President, IACC; Mr. Suresh Kotak, Chairman, IACC Textile Forum; Mr. Balkrishan Goenka, Chairman, Welspun Group delivered Keynote address; Mr. Edgard D. Kagan, Consul General, US Consulate, Mumbai as Chief Guest; Ms. Poorvi Chothani, Regional President, IACC, WIC; Ms. Rajyalakshmi Rao, National Executive Vice President, IACC, WIC; Mr. Naushad Panjwani, Regional

Vice President, IACC, WIC. The conference also witnessed participation from two leading States of USA, North Carolina and South Carolina Department of Commerce, showcasing investment opportunities in setting up textile unit in respective states. US Commercial Service, US Consulate, Mumbai made a presentation showcasing Select USA

Investment Summit scheduled 10 – 12, June 2019 at Washington, DC.

The American textile sector is driven by superior technology & high-end innovation having stronghold in every segment of textile manufacturing, starting from heart valves and stents to aircraft bodies and advanced body armor, intelligent fabrics, scientific athletic wear and home textiles, automotive textiles, geo membranes to even the delicate lingerie. Indian companies can learn and collaborate with U.S. companies and participate in

the U.S. textile manufacturing opportunities involving FDI into the U.S.

Similarly, the Indian textile industry exhibits the rich cultural heritage of India and now with its newer modern manufacturing systems, achieving wider variety of fabrics, techniques and innovation across various manufacturing techniques and uses.

India’s competitive advantage in fiber to fabric, along with its many textile clusters, can meet the ever-growing demand of the American textile industry. Indian states and companies can also attract FDI from the U.S. to promote textile manufacturing and trade.

Inaugural Session: America First & Make in India: Together Achieving USD 100 Billion Trade in Textiles.

L to R: Mr. Naushad Panjwani, Regional Vice President, IACC; Ms. Rajyalakshmi Rao, National Executive Vice President, IACC; Mr. Balkrishan Goenka, Chairman, Welspun Group; Mr. Edgard D. Kagan,Consul General, US Consulate, Mumbai; Mr. Suresh Kotak, Chairman, IACC Textile Forum; Ms. Poorvi Chothani, Regional President, IACC, WIC; Mr. S. K .Sarkar, National President, IACC

Mr. S. K. Sarkar, National President, IACC

He mentioned that;

Exports of ready-made garments dropped to US Dollar 16.37 billion in 2018-19 from USD 16.71 billion a year ago. But still garment segment is a major segment of employment generator with 45 million employed directly and another 20 million indirectly.

Policy intervention by present Government through introduction of 100 % FDI (automatic route), integrated textile parks, Technology Upgradation Fund Scheme (TUFS) all have been quite encouraging.

Fiber consumption has 70 % share through man-made fibers and only the balance is 30 % natural fibers

Sustainability is the way forward for textile industry to operate. Environment unfriendly behavior may be coting the globe an annual USD 160 billion. Raymond in collaboration with Reliance Industries aims to redeem nearly one million pet bottles from Landfills. The brand Eco-Vera.

North Carolina State University researchers have designed a fibre that combines the elasticity of rubber with the strength of a metal, resulting in a tougher material that could be incorporated in to soft robotics, packaging materials or next generation textiles.

Tirupur Exporter’s Association (TEA) India’s leading knitwear or readymade cluster has reported 8.3 % growth in terms of exports at Rs 26,000 crores in FY 19 along with a domestic sale of Rs 24,000 crores.

Changing design patterns, life style across the planet, skilled workforce, per capita spending on garments clearly indicates India’s advantage over rest of the countries, I am sure will be able to grab the opportunity.

Mr. Suresh Kotak, Chairman, IACC Textile Forum

He mentioned that;

Needs of both the countries are same (jobs and employment)

Peter F Drucker a management guru once said trade follows investment

100 billion will be achieved through trade, commerce and joint investment

Michael Porter competitive advantage economics is over. In the present era, collaborative economics is required. A great relationship can be established between the countries

IACC Textile forum is a body to make bonding between both the countries much deeper and stronger in textiles. This forum is involved in idea creation, forming new concepts alienating traditional concepts and introducing new forms of trade

We have to be pragmatic in taking the trade forward between the two countries

We are opening a new chapter of developing trade relations with America in Textiles

Mr. Balkrishan Goenka, Chairman, Welspun Group

He informed that;

This is an important initiative if we are thinking of creating more jobs

This kind of conference helps in engaging both the governments and entrepreneurs this would definitely textile sector will be benefitted.

I believe Indo – US partnership offers tremendous opportunities in terms of trade relations and growth opportunities.

We are all proud the way India is functioning, with 7 % GDP in last many years. We are hoping for a stable government for next five years which will be extremely important in carving a new growth story for “Resurgent India”

We are the first one to have state of art manufacturing plant in home textiles and started exporting

Each one of us is the first ambassador for our Country. Commitment is important, “Dare to commit” is a slogan on which we work.

Welspun has 50 % market share in home textiles in USA and every 5th towel used in USA is manufactured in Gujarat

It’s important that our country is need developmental institutions, which could fund traditional industries.

Textile is a traditional industry and it can’t be left behind

We have huge raw material; we are top producer of Cotton and top manufacturers of man-made. Our Honourable Prime Minister, has formulated an important theme from “Farm to Fibre” and “Fibre to Fashion” which can wonders for the entire textile value chain.

A small country like Bangladesh 18 b exports, how is it possible, we need to change perception and with insignificant insight, we can achieve a lot, with every 1 cr. Rupees spent in garment or apparel we can create more than 75 jobs

We are aiming to be 5 trillion economy by 2025.

Global Textile & Apparel trade would be roughly 750 billion dollars in next five years it’s projected to touch 1 trillion dollars

India is hardly having 5 % share, 40 billion exports.

There is huge scope in terms of exports to USA. We need to grow at CAGR with 10 % from currently 5 – 6%.

When India & USA is already having great partnership and relationship and with China vacating the space and we have huge opportunity. We can do wonders together and grow together.

My personal view is to work towards achieving this theme by 2025 within five years.

Mr. Edgard D. Kagan, Consul General, US Consulate, Mumbai

He mentioned that;

The first relationship built between USA & India is on textiles. Tremendous global shift in capital,investment

am happy that Mr. Kotak is talking about a vision which is not a “Zero Sum Game”

There has to be win- win not only in economic terms but also in creation of employment and values between both the countries. We can increase in textile trade significantly

We have administration in US greater focus on trade & goods, trade deficits and willing to take action, Americans play a level playing field

If there is a genuine market access across the board this will help all the countries to develop and grow and bring prosperity to citizens

In America, we are trying to refine opportunities the benefits of investments are shared by all citizens

If India continues to grows with more than 7 % then it will add entire economy of Vietnam

We are very proud threat American companies are long time investment partners in India and vice –versa

Indian companies invested in America have appreciated & found out value from investment. We have significant investments between both the countries

We see this linkage as a great opportunity This is a way forward for both countries

I can firmly say; no relationship can ever be compared with India. This will benefit not only to Indians or Americans but to everyone

We will be having defining relationship if not the defining relationship. We want a very close, strong & productive relationship with emerging India. We share very common values, the trade partnership which we have built over the years is more than economic partnership and will result crescendo for textiles industry

Textiles is important for America too. It’s always achievable to achieve the target. US exports Technical Textiles to India and we would seek partnership in developing particular segment

Session on: Investment Opportunities in Select States of USA

L to R: Mr. Colin Kiser, Senior Director, Economic Development – Europe and India Economic Development Partnership of North Carolina; Mr. Tarun Gupta, Managing Director (India Office), South Carolina Department of Commerce; Ms. Poorvi Chothani, Regional President, IACC, WIC; Mr. Rahul Padmanabha, Director of Investments, India Office, Economic Development Partnership of North Carolina;

Ms. Jigna Mehta, Commercial Specialist, U.S. Consulate, Mumbai; Mr. Sven Gerzer, Vice President, Economic Development -Europe, India & North America, Economic Development Partnership of North Carolina

In this session, presentation was done by US Commercial Service showcasing various services being offered by FCS in attracting investments in to USA and helping Small and Medium size enterprises in exporting to various countries. The presentation also covered Select USA Investment Summit which is scheduled 10 – 12 June 2019 in Washington DC. Select USA is a U.S. government-wide program organized by International Trade Administration at the United States Department of Commerce.

Exclusive presentation by two select states of USA North Carolina and South Carolina showcasing investment opportunities & locational advantage in setting up industries.

Panel Discussion I: What America Buy or Can Buy in Textiles

L to R: Mr. Nanik Rupani, Past Regional President, IACC, WIC; Mr. Updeep Singh Chatrath, Deputy CEO, Sutlej Textiles & Industries Ltd.; Mr. R. D. Udeshi, President (Polyester Chain), Reliance Industries Ltd.; Mr. Avinash Mayekar, Managing Director, Suvin Advisors Pvt. Ltd.; Mr. Sanjeev Saran, Managing Director, Reeti Exim & Application Pvt. Ltd. & Ex-Chairman, SRTEPC; Mr. Mohit Jain, Vice-Chairman, Indo Count Industries Ltd.

Mr. R. D. Udeshi, President Polyester, Reliance Industries Ltd [Session Chairman]

HE mentioned that;

Indian Textile Industry is roughly around 142 billion dollar (100 domestic, 42 exports)

India has put an ambitious target of achieving 35o billion dollar by 2024

India is blessed with entire value chain 6 MT of cotton, abundant fibre, we have refining capacity, xylene, Para xylene

India is strong in providing back end infrastructure like electricity, cheap labour, market accessibility backed by strong banking, legal system

India is strong in fibre and multi utility of fibre can help us in meeting USA Demand

How to increase trade with USA, manmade textile and mutual export to USA or create a building block in India exporting primary product to USA or processing facility can be Made at USA

Mr. Updeep Singh Chatrath, Deputy CEO, Sutlej Textiles & Industries Ltd.

He informed that;

Since the facility have in USA & How was your experience in doing business with USA?

We always wanted to have strong foot print in USA

Speed to market strategy is required as there is extreme demand

Per capita consumption of towels in US market is 8 to 10

In India the per capita consumption of towel 250 tons per day and 95 % goes to USA

Ease of operation is a plus point in USA

As a company, we are determined to grow and achieve 100 million dollars in USA

Some of the disadvantages integration of two companies or joint ventures and time difference

Rationalization of cost needs to be done while making investment in USA

Mr. Mohit Jain, Vice-Chairman, Indo Count Industries Ltd.

He spoke that;

Today 49 – 50 % of towel imported to US or bed linen imported to US is from India.

India plays a significant role US imports in home textiles

Company needs to be innovative, product development focused

The market is growing at 3 to 3.5 % in home textiles

The product exported is very straight

Import tariff to US is 7 %, Bangladesh is tariff free, Canada which is neighboring to US has 17 %

Challenge is to think from consumer’s point of view and USA being extreme developed market, there is a need to have well researched product development & innovation

Sustainability is the key to survive in future and E-Commerce is the way forward for business to operate.

Mr. Sanjeev Saran, Managing Director, Reeti Exim & Application Pvt. Ltd.

He mentioned that;

The manmade fiber which India currently exports to US is 5 % as compared to rest of the world, therefore one can imagine the potential in terms of export

We are bit underexposed in US markets. We have the raw materials but not technology

Synthetic & technical textiles huge scope. Technology can be imported, weaving can be done in India, finishing of product can be done in US

Collaborations is important, we are trying to figure out how can we work together

Product basket to USA is too small. Small woven fabrics for US defense needs to be explored more

Enhance product basket is necessary. JVs is required in terms of finishing product

India needs to improve on processing facility

Tariff barriers is not a big problem

Mr. Avinash Mayekar, Managing Director, Suvin Advisors Pvt. Ltd.

He informed that;

To achieve this target 100 billion target, provided if we go for value added products

Most of exports is yarn, which is least in the value chain

In technical textiles, US is far way ahead and making huge investment in research

Indian companies like Welspun & Gina Filament in technical textiles space making it good impact

Cotton is a major product for India

Home textiles is also a part of technical textiles and captures 50 % of market share in US

Research needs to be applied research and need not be developmental research

Outcome of the Panel Discussion:

IACC feels there is a huge opportunity to export product to USA or investment can be made at USA, greige products can be exported to US so that final processing can be done at US, so that regulatory requirements can be made at met. This will help in meeting domestic demand & US defense industry.

So, 100 billion dollars can be achieved in near future. Major contribution to be made by manmade fibre and government needs to give attention with introduction of fibre neutrality measure, this will also generate employment in the sector.

The world ration for made ups is 60 % and other 40 %.

Panel Discussion II: Current Textile Product Basket from India to USA and How to Expand, Develop & Diversify.

L to R: Mr. Arvind Sinha, Advisor, IACC Textile Forum; Mr. Prem Malik, Vice Chairman, NSL Textiles Ltd; Mr. Amol Gaikwad, General Manager, TRIMS (CVBU), Tata Motors Ltd.; Ms. Chandrima Chatterjee, Advisor, Apparel Export Promotion Council; Mr. Kailash R Lalpuria, Executive Director & CEO, Indo Count Industries Ltd.; Mr. Anjani Prasad, Managing Director, Archroma India Pvt. Ltd.

Mr. Arvind Sinha, Advisor, IACC, Textile Forum [Moderator]

He mentioned that;

Business Prospects with USA needs to be improved and has lot of prospects for both countries to explore in textiles

US defense forces market is itself 74 billion but product has to be made in America. Entrance to super markets will be easy. Why we are not able to deepen trade linkage with USA what are our weakness and strengths and how can we improve?

Mr. Prem Malik, Vice Chairman, NSL Textiles Ltd.

He spoke that;

World trade 700 billion above roughly growing at 4 -5 %

US in terms of textile and clothing 115 billion market for imports. China holds 36 % market share

Home textiles India has really done well. Total market share 15.6 billion dollars, India has 2.8 billion dollars of exports to USA, India holds 16 % market share. Relative terms, India has achieved on two items bed sheets and towels. Poly cot Pakistan has a major share and India needs to explore more on those areas.

Synthetic polyester needs a push. Government needs to give impetus.

Major weakness for India is apparel industry, out of 115 billion dollar, 83 billion dollars’ worth of imports is in apparel. India’s export in terms of apparel to USA is about 3.86 Billion about 4.6 % import

The scale of production is important in order to export to USA. Fiber area we are holding 7 – 8 % market share in US

Missing areas such as women & girls suits, women pajamas, and women’s undergarments

Second area is technical textiles. This can be the areas of focus while dealing with USA

Mr. Amol Gaikwad, General Manager, TRIMS (CVBU), Tata Motors Ltd.

He informed that;

40 – 45 sq. meters of fabric is used in automobile. Classified as technical textiles

Classified in to various categories such as seating fabric, woven fabrics (i.e. roof lining), and third one is tyre applications, high performance requirement is air bags, heat stabilizers, air filters. Textiles is used as reinforcing areas. Quality is important

Value addition is important and cost plays an important role in automobile applications

Applications changes in meeting regulatory requirements.

Mr. Kailash R. Lalpuria, Executive Director & CEO, Indo Count Industries Ltd.

He mentioned that;

Role of design studios? What are u expectations from US markets?

Post quota has helped the leaders to explore global markets. Home textiles is identified as one such area which can contribute maximum revenue

85 % of textiles are exported from China, India, Bangladesh & Vietnam

Bed linen came in to picture after 2005. India was well established in spinning long staple, medium staple & short staple

India lags front end of the market. We changed the strategy let’s invest in designing, showrooms. We have large showrooms, US, Charlotte, Manchester, Dubai

Bedding side, 4 billion dollar market out of 28 billion dollar in US home textiles. 14 billion is bedding alone, 4 billion sheets, 5 billion is fashion, 3 billion is utility, 2 billion is institutional

Vision is to become expand in bedding segment & value added segment, by investing in structured research and design studios

Ms. Chandrima Chatterjee, Advisor, Apparel Export Promotion Council

She mentioned that;

In textiles there are 265 categories of HS Codes. India is present 46 %. 25 products are categories which are currently exported

8 billion dollars of exports of apparels only 50 %

Made ups has 37 %. Textiles are minimal

We are stuck to certain 20 categories which is basic cotton, manmade fibre, knitted or woven

We are not there at all in outer wears, texture or value-added segments

Cambodia recorded 74 % growth

20 – 25 % cost in wages cannot be looked at. Wage component needs to be lower

Today’s conference is important, huge opportunity in collaboration in identifying products which are in demand. For ex fitness & health apparels, which US is looking only product differentiation needs to be done

Another area government official identifying 200 technical textiles code identified. Protective wear is important

More products is AI driven, so new age skilling is required. We need to invest in skilling. We can think of joint ventures or finishing can be done there

Plan for next 15 years, collaborative approach can be adopted. JVs can be looked at where merging of strengths needs to be done

Mr. Anjani Prasad, Managing Director, Archroma India Pvt. Ltd.

He informed that;

Ethical is crucial which textile industry can show it to the world. Ethical way of manufacturing is crucial for the textile industry

Polyester recycling is possible but cotton recycling is a problem. Reactive dyes can never be stripped

Some alternative solution for resins. We need to show to USA, different way of manufacturing

Ring spun we are using it, No open end processes in India, are we understanding customer needs and aligning processes as per America requirement

Innovations & sustainability is the key to survival for textile industry

1000 liters of water are required to produce jeans. In dyes & chemistry industry we have solution where we can produce jeans without consuming enough water. Pigments can be used where minimal consumption of water. For example, in USA, the company is based at Seattle where there is no need of water. T Shirt is being manufactured where there is no need of washing of T-Shirt

In my views, if you need to compete with China it can never on volume it should be on the basis of diversifying your product and develop niche segment.

Panel Discussion III: Success Stories of Indo – US Investments in Textiles

L to R: Mr. Harit Mehta, Member, IACC Textile Forum & MD, Haren Textiles Pvt. Ltd.;

Mr. Ajay Kohli, Senior Vice President, Archroma India Pvt. Ltd.:

Mr. Pradeep K. Mukherjee, Senior Consultant, Gherzi Consulting Engineers Pvt. Ltd.

Mr. Harit Mehta, Member, IACC Textile Forum [Moderator]

He mentioned that;

The journey begins with 100 Billion trade with America

IACC Textile Forum & US Commercial Service will help you your business grow

Nations do compete with global supply chains

Yarns fabrics to garments, dies & chemicals, multitude of fabrics, technical & non-technical

Nations don’t compete on product & services alone, they compete on supply chains

Nations do business with each other when both are treated equal & both are benefitted

Through all or effort we need to make India win & USA wins

Panel Discussion would focus on what we need to do when we commence business with USA

Are we ready to meet their demand? Doing business with America is as easy compared to any other country? We have common belief & strong ethics in doing business with America Four things are important from America perspective

a. Cheap prices doesn’t always sell

b. We need to be consistent what we make and what we sell

c. Adhere to your specification

d. Need to change & adapt if you are willing to sell America

Mr. Ajay Kohli, Senior Vice President, Archroma India Pvt. Ltd.

He spoke that;

How we need to build & strengthen our offerings while dealing with America

This is basically the value chain of the textile industry, from yarn to finished fabric, we need to look at how we recycle the fabric

Offer sustainable solution to textile industry. It has three components safe, efficient & value offering. Everything we do must be safe throughout & safe to wear, efficiency means that we should maximize the use of resources by use of your productivity, efficient maximize our productivity by minimal use of resources and we talk about enhancement means inclusion of more functionality in textiles

We need to value the environment. The global environment speaks about following facts:

6 million of chemicals only in textile industry 20 % industrial water pollution is contributed only by textiles 5 % of the entire land fill waste is occupied by textile industry

We need to use chemicals in making it more environment friendly

Innovations follows sustainability. Innovations which we have implemented smart repel, magic blue, advanced dies, earth colour this are the offerings to improve functionalities. This are digital process no capex requirement. For example:- Blue magic discontinues treatment, we have applied to textile mill the process which was taking 360 mins, we could reduce the process time by 97 mins, in terms of efficiency it has reduced water consumption by 21, time 35, energy 28, chemical two and half percent

Mr. Pradeep K. Mukherjee, Senior Consultant, Gherzi Consulting Engineers Pvt. Ltd.

Mr. Pradip Mukherjee, played video showing Use of Disruptive Technologies in Manufacturing USA. With the introduction of disruptive technologies using digital transformation, manufacturers can now achieve higher productivity, reduce labour costs and shorten lead times between order and supply.

He mentioned that;

Textile 4.0 as a subset of industry 4.0 offers a more comprehensive, interlinked and holistic approach to manufacturing

Global Trend in Textiles:

With the dismantling of MFA in Jan 2015, the industry saw the opportunity in rapidly growing its global share by becoming more competitive and expanding its capacity using modern technology

The retail markets in USA and in other developed countries are undergoing a huge structural change. From the traditional brick and mortar stores, internet commerce is accentuating changing lifestyles and consumer tastes by giving space to online marketing. As a business model, Amazon has emerged as the largest apparel retailer in USA.

Possible Opportunities for Indian Textile Industry- Spinning Sector

a. one of the key differentiators is the availability of good quality clean contamination free cotton- where USA is at an advantage

b. Import of USA cotton in to India is growing at a CAGR of 48 % from 2015 to 2017

c. Power costs in USA are one of the lowest in worldwide

d. Indian entrepreneurs may assess the cost benefit balance of reshoring part of their capacities to USA Opportunities for Indian Textile Industry (Technical Textiles):

a. while India has a growing output of technical textiles, it still imports products at the upper end of the spectrum

b. USA can provide technical knowledge, expertise and credibility based on its strength in R & D for the upper end

c. Manufacture in the USA will enable such certified products to obtain market access globally based on the accreditation

Outcome of the Session:

a. Softer side of doing business plays an important role

b. Performance & trust building is key to sell business

c. Add more products to the existing business

View of the Audience

View of the Audience