Radhey Krishna Cotweaving, established in Kishangarh, Rajasthan in 2019, follows sustainability from the initial use till the final use. Keeping this motto, the firm is not only concerned with sustainability of environment but also takes care of its employees working in the firm. The firm has taken an initiative to continue sustainability and spreading awareness for the betterment, said Mr. Sanjay Gupta, Director of Radhey Krishna Cotweaving, in an exclusive interview with Textile Value Chain.

Excerpts:

Steps taken towards Sustainability

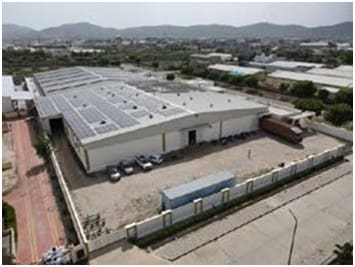

We are right now on 100% renewable energy that makes us a zero Carbon Footprint company and as we are based in the Kishangarh High Tech Textile park it has its own wind energy plant and our factory is equipped with solar plant for power generation, That makes us totally on renewable energy with 80% from solar energy and the balance 20% from our wind energy.

Products

Right now, we are only into greige cotton and cotton blended fabrics. For cotton & blends we are dealing from 6 counts till 30 counts. We are equipped with Air-jet & Sulzer looms. The qualities which we are dealing into starts from 130GSM till 444GSM, with width from 76CM to 355CM.

We are majorly selling most of our fabrics for making canvas bags which are coming out now in new trends; we are specialised in canvas fabric. We are also making canvas painting pads fabric, another major segment. For these products, we use recycled yarn. We are keen to export our products, but right now we are unable to export since we are currently into greige fabrics which are the raw fabrics and not much in demand. We are currently selling in the domestic market, but our 99.99% clients are exporters only who are exporting bags, cushion covers, bedsheets, garments, home textiles. Daks India Pvt. Ltd. is one of our clients who is dealing with great brands like Louie Vuitton, Fendi, Ralph Lauren, etc they make dust bags form our fabric we supply to them.

Invention of a new fabric & expansion

We are introducing a new range of RPet fabric which is a 100% recycled fabric made of plastic bottles that is certified by GRS for which we also provide100% traceability of everything. We will be introducing OBP fabrics in 6 months, that is Ocean Bond Plastic fabric, which will be made from the plastic waste sourced from the ocean i.e dumped in the ocean and returned back to the land. We are certified by Control Union for GOTS & GRS, which enables a complete traceability. Certification anyone can get but providing a traceability from scratch till the finish product is a task and we are working on it and we want people to get aware about it, so that they know the value of such products.

Our expansion depends on how the market accepts us because sustainability comes at a cost and if the market is ready to bear that cost then we can expand to a great extent.

How did Covid-19 impact the business of your company?

We got a very positive response during and after Covid because people became more aware about the cli- mate and got knowledge about sustainability, and this helped us a lot. After Covid we could double our production.

Promotion about the firm and its motives

We are talking to our clients and other people we are in touch with to spread the awareness. We have a website and we are in all channels of social media right now. We are promoting through our own corpo- rate videos and short clips on YouTube as well. We are trying our level best to promote our concepts.

How do you follow the principles of sustainability as it is on a niche stage?

When it comes to our company, as we are located in a textile park, they have their own recycle plant for wastage. They have their own sewer systems plus whatever cotton waste we generate while processing our fabric, we sell it to a recycler. We have a track record of that too. So, you can say from when the yarns are sent to us, till the fabric is fully used, whatever the wastage, be it fluffs or anything like side threads everything we sell it to recycler. The recycler gets it recycled and makes yarns out of it, nothing is wasted. The packing mate- rial, when it comes to yarns whether its PP, or paper tubes, or polythene or anything, we make sure every- thing gets reused somehow. We have a client base for that as well, we are selling each and every paper waste of that. Every pp fabric is sold and nothing is a waste. We are not dumping anything and we are entirely re- using everything. We are following sustainability from the scratch; we have 100% eco friendly electricity, then we are sourcing yarns which are recycled, and we are making fabrics out of the recycled energy, so that is sustainable. Whatever is dumped like water waste and all, in the textile park they have a plant which recycles it, there is no water waste also.

We take care of the labourers. Since we all know labours cant wear mask’s which is provided to them, which breathing their intake includes fine particles of cotton also, ayurveda has a simple remedy jaggery dissolves it. So, in morning we ensure they consume it, while they enter for shift and also do the same when they end their work. Its an ayurvedic cure which helps them, so that they are not prone to any kind of diseases. In personal life as well, whatever garments we have been using, we are recycling them as well. We have vendors for them who are taking them, shred- ding them and then reusing the fabric. Just not us, we have taken an initiative to spread this concept too. Every brand now is working towards sustainability. I think in a year or so you’ll be seeing more sustainable fabrics in the market.

There are a few garment stores which say that they are 100% organic but by threads of polyester, you can’t claim it 100% organic. Since they are using threads and buttons which are not sustainable, 100% sustainability is not possible for garments. When I am claiming that it is 100% recycled fabric, it maybe 80% cotton and 20% RPet or like that. So this is the difference, I am making people aware about. Take for instance, the paper tubes also. Why not we make our buyers aware that this paper tube is recyclable. So please collect them and sell them to some vendor who recycles it. We are making our supply chain also aware about the things we are doing, but to get it documented is a task. So this is the whole story when it comes to the industry, and when it comes to personal life

As being a startup how was your journey?

We started in 2019, It was a very interesting journey, frankly speaking; first we saw two waves of Covid, then now we are seeing the shooting up of cotton prices and sustaining in three years you know, the graph was like ups and downs, so it was never stagnant. Nevertheless, we are trying our best to work it out. As the prices of raw fabrics are increasing, Recycling will definitely be the next future. But recycling is also very expensive. Sustainability also comes with a cost, because it takes efforts, it takes labour, it takes transportation to get the raw materials; then to get it recycled, so cost benefits are also there but additional costs are also there. So, we have to see how people accept all this and move towards sustainability. I hope Covid has taught us a lot about sustainability. Now India has a bright future, looking at the problems that China has been facing, and Sri Lankan issues at the moment. But I think we really have a good future in textiles.