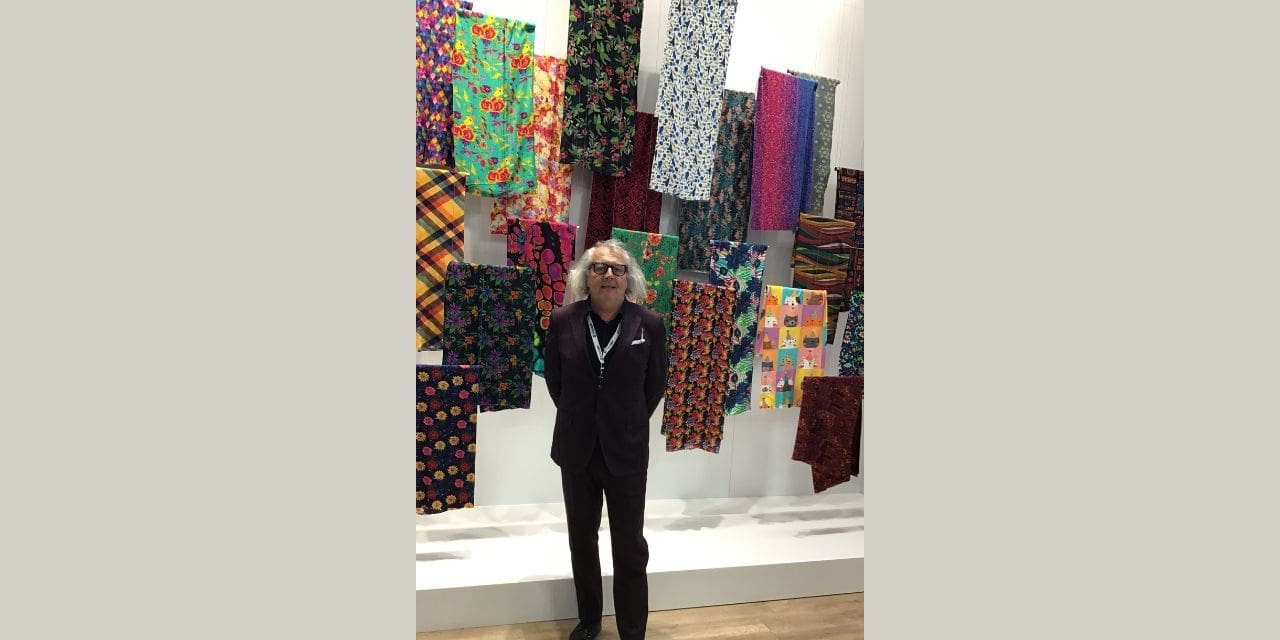

Michele Riva, Sales Director at ColorJet

ColorJet, a name synonymous with cutting-edge digital printing technology, has been at the forefront of innovation since 1995. With over 1500 years of combined experience in the field, they’ve established themselves as the leading provider of state-of-the-art large-format printing solutions. Their focus lies in exceptional speed, flexibility, and quality, ensuring customers can bring their creative visions to life.

Today, we have the pleasure of speaking with Michele Riva, Sales Director of EMEA, LAM & NAM Markets at ColorJet. Michele boasts extensive experience in the textile printing industry, encompassing both digital and traditional methods. His expertise extends to various fabrics and textile machinery, making him a true asset to ColorJet and the industry as a whole.

Prior to joining ColorJet, Michele honed his skills as Global Sales Director at industry giants like BOBST, EFI, and Reggiani. In these roles, he led successful sales teams and provided customers with tailored solutions. His impressive career further includes sales positions at other prominent textile companies.

Michele’s vast knowledge and ColorJet’s commitment to excellence promise a fascinating conversation. We’ll delve into the exciting world of digital printing, explore ColorJet’s innovative solutions, and gain insights into the future of this ever-evolving industry.

What’s your story? How did you end up linked to ColorJet?

My name is Michele Riva, and I have a background in the textile business, which I worked in before transitioning into the printing industry, specifically digital printing, for the past 20 years. I held the position of Global Sales Director for Reggiani for 15 years before joining Bobst Group in 2019 to work on a special project. After three years with Bobst Group (2019-2022), I joined ColorJet in 2023.

What are the advantages of digital printing that led to its rise in textiles?

The digital printing industry has seen a significant shift from traditional printing methods towards digital textiles in recent years. This trend can be viewed in two segments: plotter businesses and industrial digital printing.

Industrial digital printing saw a major leap forward around 2011 with the introduction of high-productivity machines by manufacturers. This led to steady growth in the industry up until 2019-2020. The expectation was for digital printing to capture around 20-25% of the global printing capacity by 2025.

However, the COVID-19 pandemic impacted this growth trajectory. While investments in digital printing continue, the pace has slowed down compared to pre-pandemic expectations.

Two main types of digital printing machines exist today: multipass and single pass. Multipass machines offer greater flexibility for printing small or medium-sized batches, while single pass machines (including high-productivity multipass models) are geared towards large-volume printing.

The primary markets for digital printing today, excluding China and India, include Pakistan, Turkey, Bangladesh, several European countries (particularly Italy, Portugal, France, and Poland), and South America (especially Brazil).

Is Turkey a big market for digital printing and how is the industry expected to grow?

The Turkish market is one of the most important for textiles, printing, and especially digital printing. The number of machines sold in the last 10 years is a testament to this. While conventional rotary screen printing will likely remain in use, digital printing is experiencing a boom and significant growth in Turkey. This is due in part to Turkey’s position as a major textile producer close to Europe, with a strong export industry. ColorJet is a new entrant to the Turkish market but with a strong commitment to global expansion. The company recently employed a direct sales manager for the country and has begun selling its equipment, with the first 32 PlasterJet printers for React set for delivery in Bursa within the next 15 days.

Can pigment inks in digital printers compete with other printing methods?

In today’s market with a variety of printing machine choices, digital printing with pigment inks offers a compelling solution for lottery ticket manufacturers. Here’s why:

- Sustainability: Pigment inks significantly reduce water consumption and eliminate the need for steam and washing processes, minimising environmental impact. This aligns with the increasing focus on sustainability within the global economy and consumer preferences.

- Versatility: Modern digital printing machines offer a wider range of printing options compared to screen printing. This allows for greater flexibility in the design and customization of lottery tickets.

- Potential Cost Savings: Digital printing can streamline workflows and potentially reduce overall printing costs.

Why should fashion brands choose digital printing over traditional methods like rotary screen printing?

Digital printing offers several advantages that make it a compelling choice for fashion brands:

- Enhanced Design Creativity: Digital printing allows for a much wider colour gamut compared to rotary screen printing. This translates to richer, more complex designs that are impossible to achieve with traditional methods.

- Reduced Waste and Faster Time to Market: With digital printing, garments can be printed on demand, eliminating the need for large production runs and minimising fabric waste. Additionally, the digital process allows for quicker turnaround times, enabling brands to get products to market faster, which is especially crucial for fast fashion.

- Potential for Reshoring: The ability to print locally with digital technology opens doors for reshoring production closer to the target market. This reduces transportation times and allows for a more responsive approach to market demands.

Does Colorjet provide any service support beyond just the machines themselves?

Yes, Colorjet offers comprehensive support to its customers. This goes beyond just the machines and includes understanding customer needs, recommending the right equipment, ink, and chemistry, and even providing design assistance. Colorjet focuses on providing solutions that encompass the entire workflow process, ensuring customer success in achieving their desired results. This approach reflects the shift in the digital printing industry where manufacturers are moving from simply selling machines to providing complete printing solutions.

Is a textile designer a cost or a valuable asset for a company in the textile industry?

While a textile designer represents a cost for a company, their contribution ultimately leads to significant value.

Here’s why:

- Skilled designers create unique and efficient designs: A talented designer acts like a “driver” who can maximise the potential of the machinery. Their expertise in digital printing allows for designs that not only enhance aesthetics but also optimise fabric usage and minimise waste.

- Design efficiency translates to cost savings: By strategically designing patterns and colour usage, designers can reduce material consumption and colour costs. This directly impacts the bottom line and generates savings for the company.

How has the response been to the ITM exhibition so far?

It is still early to say definitively, but the expectation is high despite some recent economic challenges in the textile and printing industries. There are many customers visiting booths, and organisers believe this is a sign that people are looking to resume investment in these sectors. The majority of visitors are from Turkey, Iran, and the Middle East, with some attendees from Europe as well. This exhibition primarily attracts visitors from the Mediterranean, Middle Eastern, and European regions.

Video Interview :

https://youtu.be/VMDxjPm2sUU?si=qMVKg0HIwbpjKHp2