Product (Nylon 6, Nylon 66), By Application (Fishing Net, Medical, Automotive, Consumer Goods) And Segment Forecasts To 2020

Industry Insights

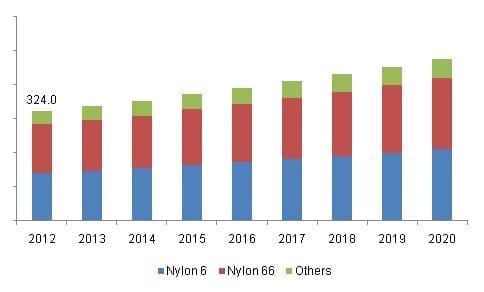

Global nylon monofilament market demand was 324.0 kilo tons in 2012. Growing fishing industry and strong automotive demand are projected to positively impact the global nylon monofilament market. Rising fish food demand is slated to bolster the fishing industry. This is further presumed to augment the industry. Growing nylon usage in consumer goods and the subsequent rise in consumer goods demand is presumed to further support the market growth. Increasing monofilament applications in the medical industry, especially in countering diabetes, is expected to complement the global nylon monofilament market. Growing demand for nylon monofilaments in the commercial and technical textiles industry as well in the gardening industry is slated to aid its demand. Increasing demand for sports equipments owing to rapid commercialization of racket sports is touted to further assist global market development. Volatile raw material prices and the advent of cheaper substitutes such as polyesters are expected to remain key challenges in the global nylon monofilament market. Growing environmental concerns regarding nylon bio-degradability are presumed to further hinder the global market. R&D initiatives to develop environment friendly monofilaments promise vast opportunities for the industry participants. Developing novel applications in consumer goods and medical applications also offer abundant opportunities for the new as well as the seasoned industry participants. Developing specialty nylons and bio-based nylons market can also be considered as a lucrative opportunity for the global industry participants.

Global nylon monofilament market volume by product, 2012-2020 (Kilo Tons)

Product Insights

Major nylon monofilament products include nylon 6 and nylon 66. These products dominate the global nylon monofilament market owing to their large production and widespread applications. Nylon 6 has lower heat resistance compared to nylon 66, but has lower costs, aesthetic advantages and other benefits such as easy color ability. These products have wide applications in the field of consumer goods, medical uses, automotive industry, paper industry and textile industry. Fishing nets, racket strings, trimmer lines, seat belts in automotives, paper machine clothing, technical & commercial textiles, wigs and concrete reinforcements are a few specific applications of nylon monofilament products. Other products include bio-based nylon monofilaments, specialty monofilaments, nylon 610, nylon 612 and semi-aromatic nylons. These specialty nylons have a narrow application scope at present, but are gaining rapid acceptance in the industry. Bio-based nylon monofilaments are similar to conventional nylon monofilaments, but are easily degradable and do not possess the harmful properties that negatively impact the environment.

Application Insights

Nylon monofilaments have a broad application scope and are used in myriad industries. Medical uses, consumer goods, automotive industry, technical & commercial textiles, and paper industry are some major end-use industries. Consumer goods dominate the nylon monofilament application market owing to numerous applications such as trimmer lines used in the gardening industry, racket strings, and furniture. Applications in the automotive & aircraft industry usually include seat belts, conveyor belts and braided sleeves. Technical & commercial textile applications include several textiles that are critical for industrial purposes such as filtration fabrics. Commercial textiles encompass the fashion industry, which has various nylon monofilament applications such as wigs and designer fabrics. Nylon monofilament medical applications, though has a narrow scope at present, are poised to grow significantly owing to growing demand as well as robust R&D initiatives. Currently, nylon monofilaments are extensively used to detect foot sensitivity in diabetes patients. This application is presumed to witness brisk growth in the near future due to the significant rise in diabetes patients around the world, especially in Asia Pacific. Forming fabrics, dryer screens and press-felts are a few nylon monofilament applications in the paper industry.

Regional Insights

Global nylon monofilament market is dominated by Europe and Asia in terms of consumption. China and U.S. play a critical role in the global nylon monofilament market as they are the largest global nylon 6 and nylon 66 producers respectively. Emerging markets such as China, India, Brazil and Russia are presumed to witness significant growth over the forecast period owing to their voracious consumer goods demand. Fishing industry is poised to grow significantly in both the emerging and developed regions. India and China are currently the largest fish producing countries. Europe and North America too are slated to witness higher fish food demand. Such a trend in developed and emerging regions is presumed to compliment the global nylon monofilament market. Emerging countries are touted to offer vast opportunities for the industry participants due to the growing automotive and electronics industry. Shifting manufacturing bases to emerging countries due to cheaper operational and manufacturing costs is expected to be a critical driver for the regional market. Asia dominates global diabetes as India, China, Indonesia, Russia and Pakistan have the maximum number of diabetes patients in the world. Rising diabetes patients around the globe coupled with aging population in countries such as Japan and U.S are slated to drive the concerned regional market.

Competitive Insights

Key industry participants are engaging in vigorous R&D initiatives to develop monofilaments with superior qualities and less environmental impact. Companies develop proprietary nylon monofilaments with special characteristics to serve particular industries. Emerging regions such as Asia-Pacific and Latin America promise ample opportunities to the industry participants. Companies are looking to expand their production capacities to meet the growing demand in the emerging markets. As a part of sustainable development, the companies are also planning to partake in R&D initiatives to develop environment friendly nylon monofilaments from bio-based sources. The major industry participants include Ashley Polymers Inc., Hinafil India Ltd., Engineered Monofilaments Corporation, Toray Monofilament Co. Ltd., Superfil Products Ltd., Ningbo Judin Special Monofilament Co. Ltd., Perlon Monofil GmbH, Luftking Enterprise Co. Ltd and Wenzhou Ruichang Special Monofilament Factory.