We are a generation of professionals who have spent their educational lives learning an unwritten theory: “Natural fibres are fibres derived from nature, and manmade fibres are fibres produced from chemicals.” However, we are also a generation of professionals who have spent their professional lives promoting sustainability, sustainable textiles, and many other environmentally friendly things. We are a generation of professionals aiming to create more environmentally friendly products. Although natural textile fibres are environmentally beneficial, their production requires the use of several resources that are not. For example, chemicals are commonly employed to impart desirable qualities to these textiles. To clean these materials for natural impurities, litres of water are often used. There have been many newly developed manufactured fibres that are environmentally friendly and sustainable over the years.

Since ancient times, conventional textile production systems have embraced nearly the same principles. The fundamental techniques of yarn spinning, surface production techniques of weaving, loop-based knitting, braiding, and felting, dyeing, printing, and sewing procedures, and equipment remain unchanged. The principles are the same; nevertheless, it should be noted that technological advancements, particularly increased manufacturing speed, are being continuously pursued to meet the consumer’s demand. Environmental concerns are eventually raised in response to rising consumer demand. Every processing step in the textile production chain has its own environmentally negative impact on the environment. Every fibre, every yarn bobbin, every square metre of fabric, every chemical, the consumer cycle time of each textile item, and the recycle or waste stage of every single T-shirt all leave their own imprint. Cotton, wool, silk, and linen, which are commonly used natural fibres, each have their own environmental footprint related to their growing-processing procedures and consumer use stages. Traditional synthetic-based man-made fibre varieties have their own raw material footprint and degradation time in nature. A new generation of biodegradable man-made fibre production technology offers intriguing sustainability prospects. Since the industrial revolution, traditional yarn production technology and processing machinery lines have remained essentially unchanged. Forecasts for the use of manufactured cellulosic fibre (MMCF) such as viscose indicate an increase in the coming years due to its superior performance and lower cost when compared to other fibres. With an average annual demand of 5-6 million tonnes, MMCF such as viscose/rayon, lyocell and modal (as well as cupro and acetate) are the second most important group of cellulosic fibres after cotton. Unlike cotton, MMCF is generated chemically from natural feedstock such as trees and plants.

What is sustainability?

The ability to continue or support a process over time is referred to as sustainability. Sustainability is frequently divided into three categories: economic, environmental, and social. Many businesses and governments have made long-term commitments, such as decreasing their environmental footprints and conserving resources. Some investors are actively pursuing “green investments,” or sustainability investments.

The goal of sustainability in textiles is to meet the demands of the present and future without jeopardizing future generations’ ability to meet their basic requirements. The three pillars are important to the concept of sustainability. There are three of them: social, economic, and environmental. Profits, planet, and people are also casual terms.

Objectives of Sustainability

Objectives of Sustainable Textile Fibers are as follows:

- Water requirements are minimal.

- Low energy requirement.

- Waste and recyclable materials could be used

- Derived from a renewable resource

- Chemical Management.

- No GMO.

- There is no soil erosion.

- Biodegradable, for instance.

Man-made fibres and sustainability

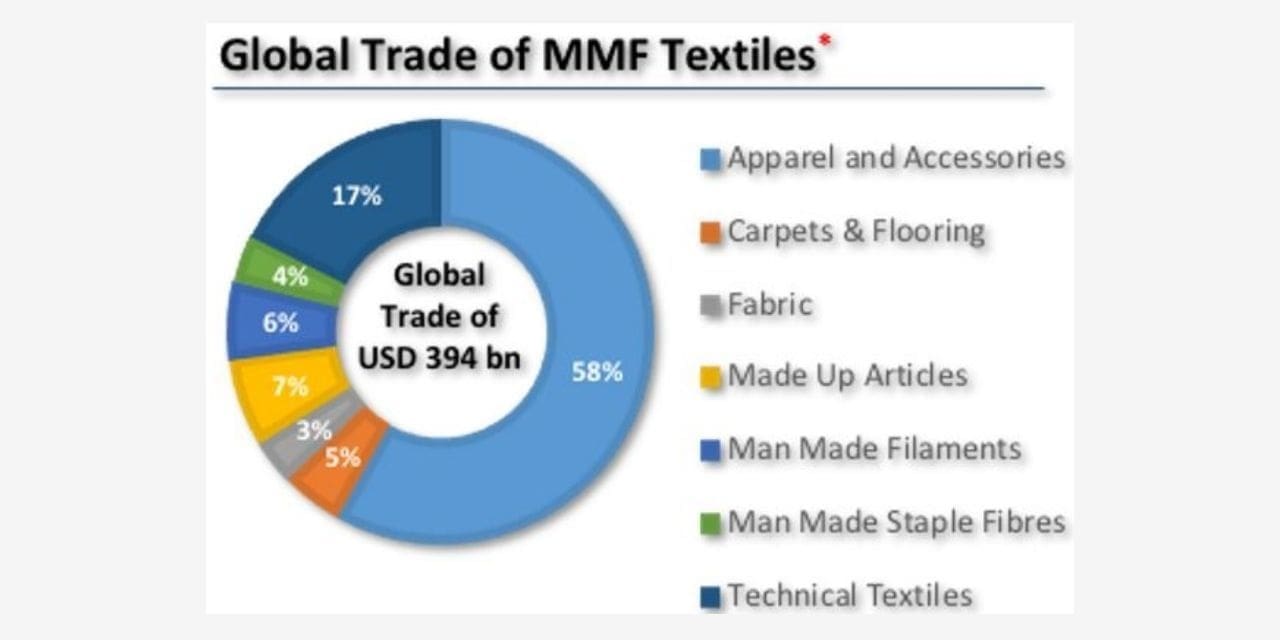

Man-made fibres account for 75% of all fibres produced worldwide. Their primary use is in clothing, carpets, and home textiles, as well as a variety of technical products such as tyres, conveyor belts, fillings for sleeping bags and cold-weather clothing, filters to improve the quality of air and water in the environment, fire-resistant materials, reinforcement in composites used in advanced aircraft production, and much more. Fibres are designed to have the best mix of attributes for the end use in mind, such as appearance, handle, strength, durability, stretch, stability, warmth, protection, ease of care, breathability, moisture absorption, and value for money. They are commonly used in blends with natural fibres like cotton and wool.

Man-made fibres are classified into two types: continuous filament, which is primarily used for weaving, knitting, or carpet production, and staple, which is comprised of discontinuous lengths of fibre that can be spun into yarn or incorporated into unspun uses such as fillings or nonwovens. Industry, and particularly the Man-made Fibres (MMF) Industry, has a long history of pursuing initiatives that promote sustainability. The consumption of energy, raw materials, and all other resources, as well as the emission of solid, liquid, and gaseous waste, determine the sustainability of man-made fibres, but we must not overlook the in-use phase, where significant environmental savings can be made, as well as the disposal or recycling phase.

Manmade Fibres (MMF) are now an essential part of our daily lives, and life would be difficult without them. These fibres have a wide range of applications, including not only textiles and apparel, but also a wide range of specialty fabrics used in technical areas. However, manmade fibres and fabrics have so far been criticised for not scaling up to the mark of eco-friendly attitude being synthetic by nature.

We cannot deny that sustainability is the current trend, and industry manufacturers must be able to answer questions about the environmental impact of their products. “End-consumers increasingly want to know if the textiles they buy are ecological, what ‘green benefits’ do textiles made from a particular material provide, and so on,” observes Trevira GmbH, a polyester giant. The company also discovers that its consumers along the textile value chain have developed a growing interest in the environmentally relevant properties of its textiles, and customers ask for concrete data on the sustainability of products more and more frequently.

The use of nonwovens for crop protection, which minimizes the demand for pesticides and water, is an example of a contribution to sustainability. Perhaps even more important than this direct contribution is our industry’s indirect contribution. Nonwovens enable the production of more energy-efficient buildings and vehicles, as well as less food waste due to innovative packaging. This, in turn, plays an important role in lowering greenhouse gas emissions.

What matters is responsible production and, more importantly, conscious consumption! Standardized and objective eco-balances assist the end user in weighing the criteria that are important in his/her choice for a specific textile and material – whether made-made, natural fibres, or blended. According to Mrs. Vollenbroker, “the benefit for the community will be that improved consciousness for environmental issues will result in greater global sustainability.”

Sustainable development is an important component of our company’s ambitions, both in production and in the subsequent processing of our fibres and yarns through to the end consumer. Some MMF help save energy during the in-use phase, which can only be realised with suitable MMF application, such as in composites.

List of sustainable MMFs

These are made from natural raw materials but are subjected to chemical procedures that have various effects on what constitutes a sustainable fabric.

- Recycled Polyester

- Viscose or rayon

- Lyocell

- Modal

- Cupro

- Seaweed fabric

- Agricultural waste products such as banana, pineapple, orange, coffee, milk

Final Thoughts

Sustainable fashion encompasses more than simply the sustainable textiles in our green wardrobe. It is the result of several variables, including supply chain transparency, ethical company practises, low-impact regulations, and community-giving programmes.

AUTHORS:

Kshipra Gadey

Fashion Design Faculty, INIFD Kothrud