The demand and supply crisis and the growth of the world population call for new ways of producing food and other essential items. One of the most complex questions is – “How to cater to the demand of food and other items for ever increasing population. First logical solution is to control the population growth rate, which will ultimately reduce the gap between demand and supply and reduce the impact of the crisis. But considering limitations of cultural, geographical and political boundaries; the solution is very complex.

Solutions to modify the way we produce goods are already being put to test around the world. Tomorrow, we may be able to build factories, in the developing world as much as in the developed world, which can adapt to local characteristics of the products for local requirement, which will belong in a sustainable supply chain and have less of an impact on the environment. Using which solutions? Are these sustainable? And can the experiments being carried out today give us an insight into the factories of the future? Here are some “sutra” which will enable the above ultimate goal.

Produce green

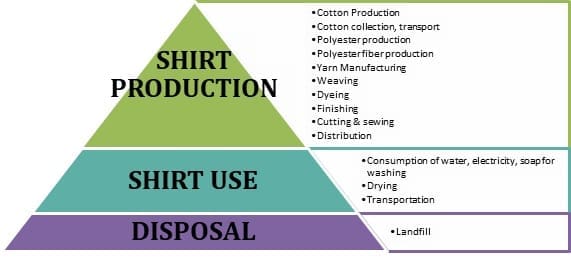

It is very important to understand the life cycle analysis of any product manufactured. Life Cycle Assessment (LCA) is used to evaluate the environmental impacts of textile products, from raw material extraction, through fiber processing, textile manufacture, distribution and use, to disposal or recycling.

For example, life cycle analysis of a shirt right from cotton production up to land disposal will be as follows-

Life cycle Analysis of a shirt

Hence, it is really important as a manufacturer to understand the amount of resources consumed not only while manufacturing a product, but also throughout the life of product and disposal of product too.

Produce locally

Locally produced goods, by using local raw material, local machinery and equipment, with local labour, for local use, will always have an upper hand against an imported finished product and technology. This thought is taken seriously worldwide by adopting “think global and act local”. Most of the times, transportation, monitoring and handling cost of a finished product is multiple times the basic manufacturing cost. If the product is perishable, there will be always some deterioration on the quality parameters too. On the contrary, locally produced material will have a positive impact on the local community through employment generation, greater service availability and more adapted functionality. Also, this limits revenue outflow through imports, and enhances indigenous production and national growth. This not only fulfills production requirements but, also creates an ecosystem that provides jobs, training and education to the people in the ecosystem which will ultimately lead to a better quality of life.

Invent sustainable techniques & technology

Companies that source manufactured goods from China do so primarily because of the attractive production costs. Now, however, cost advantages are harder to come by. Companies have reached a point at which there is little cost remaining to be squeezed out of the on-ocean shipping process. Hence, sooner or later, it is important to invent and invest to invent on sustainable technologies which will help the production costs in long run.

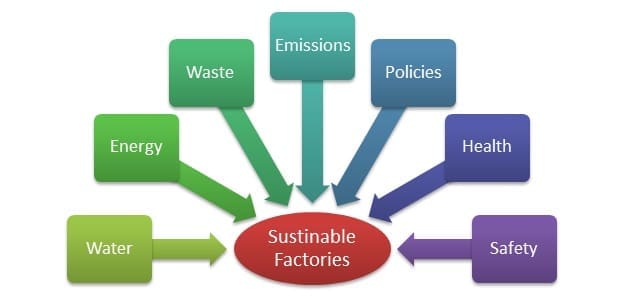

Sustainable factory ecosystem

Sustainable Factories / Manufacturing Units

With the above background and context of the need for sustainable products, it is absolutely necessary that sustainable products must be supported by sustainable production. Sustainable production is absolutely dependent on sustainable resources for production.

The whole idea is to “produce our own energy and stop polluting and wasting”, a strategy that could quite easily be replicated on other production sites, including large and traditional factories. This is the first trial for the future: in order to keep producing finished products for everyone and, at the same time, to limit the impact of this production on our planet as much as possible, we will have to come up with new energy models. This will create a production chain that works as an ecosystem, with little waste and little pollution, which makes the most of available, natural and renewable resources.

In order to achieve this,some of the basic resources are water and energy. When a production eco-system’s dependency on outside resources is zero or very less, the eco-system become more and more sustainable (exactly like less cash economy if not cash less India is blessed with abundant sunlight and surplus rainfall almost everywhere in the country. Hence, the problem is no longer about availability of water and solar / wind energy but it is about right approach to handle the same. The implementation of sustainability philosophy includes study of existing available resources, availability of them throughout the year, average cost of water or energy per unit, topography and many more. It is important to set out manufacturing sustainability strategy and activities. With the implementation of new tools, techniques and technologies; the environmental impact can be definitely reduced.

The key focus areas should be –

- Reducing environmental impact of current production processes, process lines of existing factories / production units

- Adopting zero waste and zero discharge philosophies in existing and upcoming production units

- Replacing existing / old heavy resource consuming technologies by new energy efficient sustainable technologies

- Carrying our water audits, energy audits and waste audits in factories

- Exploring renewable opportunities for replacing current conventional fuels / energy sources like coal, LDO, furnace oil, diesel, conventional power by solar energy, wind energy, biodiesel, biomass, agro-waste for boilers, furnaces and other power consuming activities

- Optimizing fuel consumption

- Efficient building design in order to have maximum impact of natural ventilation, natural sunlight and thus reducing cost of HVAC and air conditioning

- Adopting decentralized approach for production in order to reduce cost of transportation as per demand and supply requirement

- Improving on supply chain management in order to reduce stocks and improve production efficiency in terms of resources and manpower and thus better utilization of space

- Encouraging incentivizing employees for resource consumption reduction and optimization

- Co-relating efficiency of resource consumption to profitability of production in order to enhance the financial feasibility of such measures.

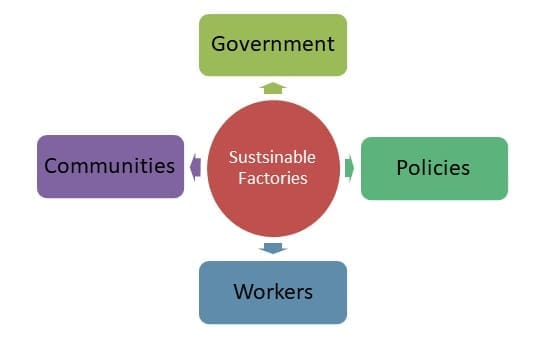

Manufacturing is completely interconnected to wellbeing of workers, surrounding communities, support of government and implementation of policies in longer run. Hence, a sustainable approach to manufacturing will definitely have a positive impact on these four aspects and overall economy to make it more sustainable and durable.

– © Chitralekha Vaidya

========================================================

Note – The article series will elaborate more on each of the above aspect of sustainability with respect to improvisation of efficiency, profits, product quality, quality of life and overall ecosystem in upcoming articles.

===============================================

About Author

Chitralekha Vaidya,

CEO, Varshasookt Consultants

Professional Civil Engineer with post graduation in the Environmental Engineering. 13 years of Extensive expertise into water management, rainwater harvesting, water audits, solar power, waste water treatment and waste to energy solutions.