It is Acordis “s brand name for a viscose fibre with a unique flat cross –section with a crenellated surface which offers softness, extra bulk and absorbency. Viloft is a speciality viscose fibre engineered for maximum thermal performance, advanced moisture management and softness. Its unique crenellated surface helps to achieve a technically advanced capillary action. Acordis is the world’s largest independent fibre producer.It was formed in January 1999 by combining the fibres businesses of Akzo Nobel with the fibres operations of Courtaulds plc. The Acordis group has sales of some EUR 1.6 billion, employs approximately 9,000 people and has production facilities in Germany, the Netherlands, the United Kingdom, the United States of America, Brazil, Italy and Poland.

Acordis supplies customers throughout the world with man-made fibres and speciality materials for industrial, textile, medical and hygiene applications.

Viloft fibres are of 3 types

- Viloft orginal.

- Viloft thermal.

- Viloft active.

Besides these Kelheim fibres has introduced a completely new fibre concept with revolutionary characteristics known as

- Viloft nonwoven.

- Viloft micro.

- Viloft spirit.

Each viloft fibre has been created for a distinct look and feel. From lustrous body skimming high fashion to soft, warm thermals, the versatility of viloft is suited to wide range of clothing applications.

In the year 2002 RSWM Ltd introduced new generation specialities yarn using viloft fibre in association with the U.K based Acordis, supplier of man-made fibre /speciality materials for the textile industry around the world in the tirupur market. The application of viloft in garments is commercially established with worlds leading garment labels/brands.

Acordis has a marketing arrangement with RSWM Ltd which will produce a diverse count of yarns spun out of viloft fibre and its blends.

Manufacturing –

Viloft is 100% natural in origin and made from eucalyptus wood pulp harvested from managed plantations.

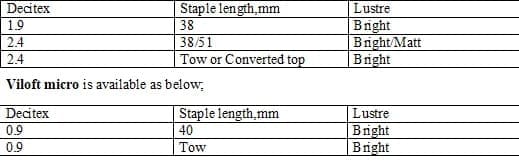

Viloft original is available as below:

Properties –

Viloft nonwoven – its modified flat cross section delivers a fibre with increased flexibility and softness when compared with fibres of conventional cross section. It also shows an outstanding performance in contact with fluids, it retains its softness and exhibits high level of absorbancy. Test results show that, during disposal, viloft nonwoven enhances the disintegration process of nonwoven materials. These properties make viloft nonwoven the ideal fibre for innovative products with new benefits for the whole nonwoven industry. It is 100% bio-degradable. It is certified for usage in baby hygiene products.

Viloft original is engineered to offer particular technical and aesthetic properties which differentiate it from other fibres. This creates fabrics and garments with an extremely soft handle for superb next –to- skin comfort.

Viloft original – its flat cross-section offers following

- Higher flexibility and softness compared to round fibres.

- Thermal performance due to the formation of air pockets within a yarn construction When blended,usually with polyester or cotton, the engineered flat cross –section of viloft traps pockets of air to protect and insulate against cold.

- Moisture management properties and wickability in blends with other fibres. Viloft breathes –moisture is transported away from the skin through the fabric by its technically advanced capillary action. Breathable garments keep the wearer dry.

- Ideal for performance base layering systems and under close-fitting outerwear.

- Garments can be washed at 40 deg c without loosing their shape, style or colour.

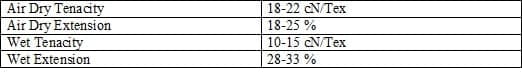

Properties of Viloft original are as below.

Viloft micro is a fine decitex fibre with a round cross-section that produces lightweight, ultrafine and soft jersey and woven fabrics.

Viloft spirit brings a tempting soft and light hand to many fashion garments adding comfort and wearability. Easy care of viloft spirit makes style even more practical, adding luxurious warmth and comfort to high fashion.

Viloft active is the perfect fibre for active sportswear. It is breathable. it is soft, due to its unique flat cross-section, making it superbly comfortable. Easy care is important in active wear – viloft garments can be machine washed at 40 deg c without losing shape. It is lightweight – ideal for base layering.

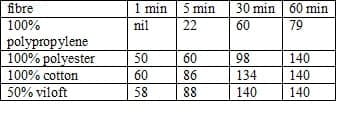

Wicking rate of viloft active

Viloft thermal is not simply a necessity, not just a fashion but a lifestyle. Thermal is here to stay – for women,men,youths and children. It is leading this thermal trend, it is desirable –recognised and valued by consumers around the world.

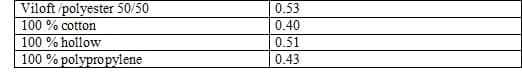

Thermal resistance value at 2 mm fabric thickness

Blending – Viloft orginal can be spun upto 60 nm . It can be blended with polyester 50/50 ratio. It can be blended with cotton 50/50 ratio. It can be blended with Amicor 85/15 ratio.

Similarly Viloft micro can be spun upto 120 nm on cotton ring spinning system although even finer counts are achievable. It can be used 100 % or in blend with most other natural or synthetic fibres. It performs well on all common spinning technologies such as ring,open end or air jet spinning.

The blend of 50% polyester, 50% viscose has many excellent qualities.

- Soft and comfortable.

- Wicking ( draws moisture away from skin )

- Moisture management.

- Thermal properties.

- Easy care ( machine washable at 40 deg c )

- Light weight.

Viloft fibre can be blended with hollow polyester fibre taking into consideration the structure and properties of Viloft fibre which influence the qualities of yarns. According to the different characters of the two fibres, the technological parameters are optimized. For the peculiarities of Viloft fibre, emphasis on the blending way of Viloft and polyester, selection of the carding clothing, the lapping in drawing process and yarn evenness.

Dyeing and finishing of fabrics containing Viloft original –

Blends of viloft original and polyester is dyed by various routes such as first polyester is dyed using disperse dyes at 130 deg c and then Viloft portion is dyed using vat dyes, sulphur dyes or reactive dyes by exhaust or pad –batch process.

The knitted blended fabric is dyed in soft flow dyeing machine. Most fabrics require a chemical antipill treatment for good pilling performance and these is given during scouring process or as a part of the reduction clearing treatment employed after dyeing with disperse dyes.

A good standard of white is obtained by bleaching with hydrogen peroxide at 95 deg c. While dyeing Viloft original/cotton blended in one bath care should be taken that reactive dyes produce a heavier depth of shade on Viloft original compared to cotton. The dyeing and finishing conditions for circular knitted fabrics containing Lycra with Viloft original need to be carefully controlled to preserve the inherent elastic properties of the yarn. The temperature, tension and duration of treatments must be kept to a minimum because the elastic properties are affected by heat and temperature.

Resin finishing is done on Viloft blended fabrics by pad, pin stenter dry and flash cure 30 secs at 180 deg c.

Uses – Viloft original in blends with other natural or synthetic fibres is used for functional textiles, e.g thermal sleepwear and underwear, sportswear, socks, shirts, outdoor clothing etc. viloft is marketed to consumers as well as manufacturers and the retail trade and it has become a household name for premium quality fibres.

Viloft spirit is used in the following areas.

- Underwear to be seen.

- Fashion sportswear.

- Leisure wear.

- Lingerie.

- T shirts.

- Jeans.

- Urban Street wear.

Viloft active is perfect for the following

- Active sportswear.

- Active thermalwear.

- Sports performance base layers.

- T shirts.

- Urban Street wear.

- Children’s wear.

- Youth wear.

Viloft thermal is a natural presentation for the following;

- Top towel,home furnishings textile.

- Classic thermal underwear.

- Sleep wear.

- Home wear.

- Leisure wear.

- Children’s wear.

- Hosiery.

Acknowledgement – The author is thankful to Mr Subhash Bhargava, FSDC ( UK), Managing Director, Colorant Ltd, Ahmedabad for giving permission to publish this article.

Dr N.N.Mahapatra

President

COLORANT LTD Plot No. 116, Phase II

Near Ambica Cross Road

G.I.D.C.Vatva,

Ahmedabad-382445