Dr. V.D.Gotmare, Ph.D (Tech.).; Hon.F.T.A.

Representative Director (India), Mumbai

Frontier.cool.Inc., Taiwan

(Former HoD, Textile Manufactures Department, V.J.T.I., Mumbai-19)

Chairman, The Textile Association (India) – Central

GC Member, TAI, Mumbai Unit

The textile industry is undergoing a transformation, one that is characterised by the convergence of three key trends: sustainability, strength, and intelligence. Textile fibrous materials are evolving to meet the demands of modern society, addressing critical environmental challenges while simultaneously enhancing functionality and performance. From bio-based fibres that are both renewable and biodegradable, to the development of smart textiles that respond to environmental stimuli, innovations in textile fibres are reshaping industries across the globe. This article will explore the major advancements in textile fibrous materials, focusing on how the industry is balancing the need for sustainability with the desire for high-performance and cutting-edge smart functionalities.

1. Sustainability: The Push for Eco-Friendly Fibres

Historically, textiles have been associated with a significant environmental footprint. The production of conventional synthetic fibres, such as polyester, nylon, and acrylic, is highly resource-intensive, consuming large amounts of water, energy, and chemicals. Furthermore, these fibres are made from petroleum-based products, which contribute to plastic pollution and are not biodegradable, leading to issues of waste accumulation and microplastic pollution in oceans and landfills. As awareness of these environmental challenges has increased, sustainability has become a driving force behind the innovation of textile fibrous materials.

Source: Trade UNO

a) Bio-Based and Renewable Fibers

One of the most notable shifts toward sustainability in textile fibres has been the development of bio-based fibres. These fibres are made from renewable, plant-based materials such as wood, cotton, hemp, bamboo, and algae. The use of these resources helps to reduce the environmental impact of textile production and limits reliance on fossil fuels.

- Tencel (Lyocell): One of the most well-known examples of bio-based fibre is Tencel, made from sustainably sourced wood pulp. Tencel is produced through a closed-loop process, meaning that the solvents and water used in production are recycled, reducing waste and minimising pollution. The fibre is biodegradable, and the material is soft, breathable, and moisture-wicking, making it ideal for clothing.

- Hemp: Hemp is one of the oldest known textile fibres, but its potential has been largely untapped in recent decades. Hemp is a highly sustainable fibre, requiring minimal water, no pesticides, and very little land to grow. It’s also biodegradable and incredibly durable, which makes it ideal for applications in sustainable fashion and industrial textiles.

Hemp Fibre

Source: Sustainable Jungle

- Algae-Based Fibers: Recent advancements have also seen the development of algae-based fibres. Algae can be processed into fibres that are not only sustainable but also lightweight, strong, and biodegradable. This new class of materials shows promise in industries such as fashion and healthcare, offering a sustainable alternative to conventional synthetic textiles.

Algae-Based Fibrous Material

Source: Textile Today

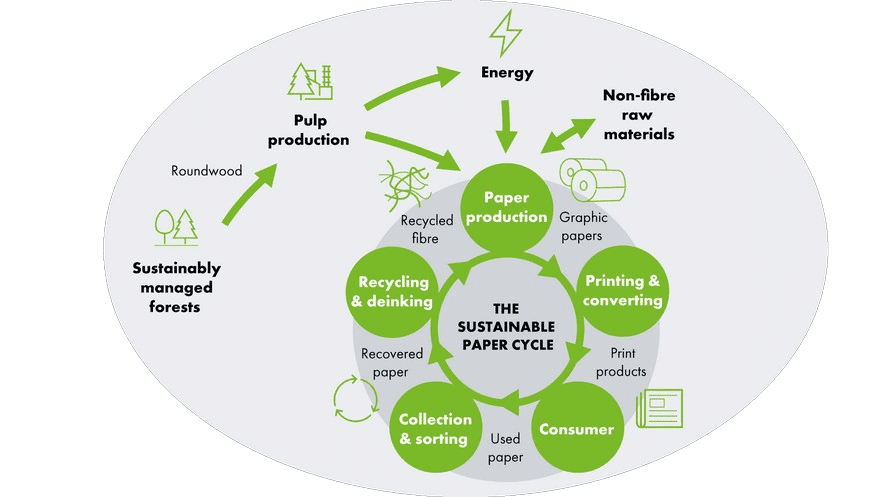

b) Recycled Textiles and Circular Economy

Another major shift in the textile industry is the growing use of recycled fibres. As the world grapples with rising textile waste, recycling has emerged as a solution to reduce the environmental impact of new textile production.

- Recycled Polyester: One of the most successful examples of recycled textiles is the use of post-consumer plastic bottles to create recycled polyester. This process reduces the need for virgin polyester, which is derived from petroleum, and helps divert plastic waste from landfills and oceans. Brands such as Patagonia, Adidas, and H&M have incorporated recycled polyester into their product lines, creating sustainable activewear and outerwear.

- Recycled Cotton: Cotton production requires a vast amount of water and chemicals, but by recycling cotton from discarded garments or production scraps, the industry can significantly reduce its resource consumption. Recycled cotton is increasingly used in the production of denim, sportswear, and other casual clothing, supporting the development of a circular textile economy.

Source: UPM Communication Papers

c) Biodegradable Fibers: Closing the Loop on Waste

While recycling is a critical part of sustainability, biodegradable fibres are also gaining traction. These fibres decompose naturally in the environment, offering an alternative to the accumulating textile waste that takes centuries to break down. Biodegradable fibres, such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA), derived from plant materials like corn and sugarcane, are gaining popularity due to their compostability and their ability to break down without releasing harmful toxins.

Unlike traditional synthetic fibres, which persist in landfills, biodegradable fibres can decompose naturally, reducing the environmental burden when garments are disposed of. This innovation supports the development of sustainable clothing that doesn’t contribute to long-term pollution.

2. Smart Textiles: Innovations in Functionality

While sustainability remains a central theme in the evolution of textile fibres, the integration of smart technologies into fabrics is also driving the industry forward. Smart textiles, or e-textiles, incorporate sensors, conductive materials, and other advanced technologies into fabrics to enhance their functionality. These textiles can respond to stimuli such as temperature, pressure, light, or moisture, opening up new possibilities in a variety of sectors, including healthcare, sports, and defence.

a) Wearable Technology and Health Monitoring

Smart textiles are increasingly being used in wearable technology to monitor health metrics such as heart rate, temperature, and respiratory rate. These fabrics integrate conductive fibres or sensors that track a user’s physiological data and transmit it to external devices, such as smartphones or health monitors.

For instance, Hexoskin and OMsignal have developed smart shirts embedded with sensors to track metrics such as heart rate variability, sleep patterns, and physical activity levels. These garments provide users with real-time data that can be used to optimise performance or manage chronic conditions, offering a new level of personalised healthcare.

Source: ResearchGate

b) Energy-Harvesting Textiles

Energy-harvesting textiles are designed to capture and convert energy from the environment into usable electrical power. For example, fabrics woven with piezoelectric fibres generate electricity when subjected to mechanical stress, such as from walking or running. This technology has the potential to power small devices such as sensors, lights, or wearable gadgets, without the need for external power sources.

Another innovative approach is solar-powered textiles, where fibres are embedded with photovoltaic cells to capture solar energy. This innovation could lead to the creation of garments or accessories that generate power to charge devices, such as phones or fitness trackers, as the wearer moves through the day. Such textiles have applications in outdoor gear, military uniforms, and emergency clothing.

c) Self-Healing Fabrics

Self-healing textiles represent a breakthrough in material science, as they can automatically repair small cuts, abrasions, or tears without the need for external intervention. Self-healing fabrics incorporate materials that respond to damage by healing the broken bonds at the molecular level. This ability to repair itself extends the lifespan of the fabric, reduces the need for replacement, and contributes to reducing textile waste.

Researchers are working on developing fabrics that can heal themselves when damaged, particularly in applications where durability and safety are paramount, such as in military uniforms or protective gear.

3. Strength and Durability: High-Performance Fibers for Extreme Conditions

Another area of innovation in textile fibres is the enhancement of strength and durability. For textiles used in extreme conditions, such as protective clothing, military uniforms, or sports gear, durability is a critical factor. High-performance fibres are engineered to provide exceptional strength while maintaining comfort, flexibility, and resistance to abrasion, heat, and moisture.

a) Aramid Fibers: Kevlar and Nomex

Aramid fibres, such as Kevlar and Nomex, are designed for extreme performance. Kevlar is renowned for its use in bulletproof vests, body armour, and protective gear due to its strength-to-weight ratio and resistance to abrasion. Nomex, a heat-resistant aramid fibre, is commonly used in fire-resistant clothing, particularly for firefighters, race car drivers, and military personnel.

These fibres are known for their toughness and resilience, making them invaluable in situations where safety and protection are paramount.

b) Ultra-High-Molecular-Weight Polyethylene (UHMWPE)

Dyneema, a brand of ultra-high-molecular-weight polyethylene (UHMWPE), is one of the strongest fibres available today. It is used in applications where strength and lightness are essential, such as in military body armour, ropes, and industrial textiles. UHMWPE fibres are up to 15 times stronger than steel, but they are lightweight and flexible, which makes them ideal for high-performance products.

Source: Titan Depot

c) Carbon Nanotube-Enhanced Fibers

The integration of carbon nanotubes (CNTs) into fibres is another promising avenue for increasing strength. CNTs enhance the mechanical properties of fibres, making them stronger, more flexible, and conductive. These fibres are being researched for use in high-performance applications such as aerospace, automotive industries, and advanced sportswear.

4. The Future of Textile Fibers: A Multifaceted Approach

The future of textile fibrous materials is multi-faceted, with innovations spanning from sustainability and biodegradability to cutting-edge technologies that improve functionality. The integration of bio-based, recycled, and biodegradable fibres ensures that the textile industry can reduce its environmental footprint, while innovations in smart textiles are pushing the boundaries of performance and convenience. High-performance fibres continue to meet the needs of industries that demand strength and durability, all while maintaining comfort and flexibility.

As the demand for eco-friendly and high-tech textiles continues to grow, we can expect to see further breakthroughs in the coming years. From self-cleaning fabrics to energy-generating textiles and self-healing materials, the possibilities for textile innovations are vast.

Conclusion

Smart, sustainable, and strong textile fibrous materials are transforming the fabric of our world. The drive for sustainability is leading to the creation of renewable, biodegradable, and recycled fibres, while advances in smart textiles are enhancing the functionality of fabrics in unprecedented ways. The development of high-performance fibres is ensuring that textiles remain durable and resilient, even in the harshest conditions. Together, these innovations are setting the stage for a future where textiles not only meet the demands of modern life but also contribute to a more sustainable and technologically advanced world.

References:

- “Smart textiles and wearable technology: A review” by L. Y. (2019), Journal of Textile Science & Engineering

- “Recent advancements in smart textiles: Materials, applications, and future directions” by R. Rajagopal, Advanced Functional Materials (2021)

- “Wearable sensors and their applications in textiles” by M. D. C. G. Sensors and Actuators A: Physical (2020)

- “Sustainability in textiles: A review of environmentally friendly materials and processes” by S. H. (2020), Journal of Cleaner Production

- “Eco-friendly textiles: The green road to a sustainable future” by T. M. (2022), Sustainable Materials and Technologies

- “Nanotechnology for sustainable textiles” by J. Lee et al. Journal of Nanoscience and Nanotechnology“Recent developments in high-performance fibers for textile applications” by L. Zhang et al., Composites Science and Technology (2021)

- “Advanced textile fibers and their applications in aerospace, automotive, and military industries” by J. N. (2022), Journal of Industrial Textiles

- “The role of nanotechnology in enhancing the strength and functionality of textile fibers” by S. S. (2020), Nanomaterials

- “Innovations in fiber technology and their impact on textile engineering” by M. H. (2023), Textile Research Journal

- “Recent advancements in the development of composite fibers for textile applications” by K. B. (2022), Composites Part A: Applied Science and Manufacturing

- “Fibers for the next generation of textiles: A comprehensive overview of smart and sustainable innovations” by T. G. (2024), Materials Science and Engineering

- “The future of textile fibrous materials: Trends and challenges” by D. P. (2024), Journal of Textile and Apparel Technology

- “Barriers to the commercialization of sustainable and smart textiles” by R. C. (2023),

- “Integrating innovation in textile fibers: From lab to market” by M. F. (2023), Journal of Industrial Engineering and Management