S K Chattopadyay and T Senthilkumar

Central Institute for Research on Cotton Technology (CIRCOT), Mumbai 400 019

- INTRODUCTION

A yarn may be defined as a product of substantial length and relatively small cross-section of fibres and/or filament(s) with or without twist, used for interlacing in processes such as knitting, weaving or sewing [1]. The basic material which is used for yarn manufacturing is staple fibres or filaments either natural or manmade. The staple fibres produce the through conventional spinning system where as extrusion spinning produce continuous filament yarn. In continuous filament spinning the fibre forming substance is forced through the holes of a spinneret beyond which it solidifies in the form of filaments. Spun yarns are produced by placing a series of individual fibres together to form a continuous assembly of overlapping fibres, usually bound together by twist. The staple yarn structure is mainly governed of the raw material quality, machine settings, twist and yarn manufacturing type such as ring spinning, compact spinning, rotor spinning, air jet spinning, friction spinning etc. The continuous yarn structure is mainly decided by yarn twist and number of fibres in the cross section. There are significant differences have been found by many research among the various types of yarns properties like strength, hairiness, thick place, thick place, neps and appearances. These properties may also change by yarn count and yarn ply variation like single and ply yarn. The yarn structure is not only the visual appearance. It has much or lesser influence on strength, elongation, insulating capacity, covering power, ability to resist wear, damage, strains, resistance to abrasion, ability to dye uptake, fabric structure, wearing comfort etc… In dyeing various yarns like ring, compact, rotor, air jet and friction yarn give the some significant difference in lightness value (L*), Chroma (C*), Colour Strenght (K/S) and Changes in colour difference (∆E*ab) value. The colour values also changes depends on the abrasion resistance of the dyed materials. In this paper, the work carried out on various spun yarns producing technique, and its properties and dyeing characterising influences on yarn structure and fabric structure.

2. Ring spun yarn

Ring Spinning is one of the oldest of the present day spinning processes. Fiber material is supplied to the ring-spinning machine in the form of a roving. The fiber mass of the roving is reduced by a drafting unit to the final yarn count desired. The twist inserted by the differential speed of spindle rotation and the yarn winding rate, moves backwards and reaches the fibers leaving the drafting unit. The fibers align around one another in concentric helical paths. The normal forces encountered by the fibers enhance the adhesive forces between them and prevent them from slipping past each other under the tensile strain.

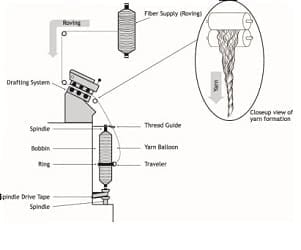

Ring spinning is the process of drawing out roving to the final yarn count and simultaneously inserting twist to the fibres by means of a rotating spindle and winding the yarn on a bobbin. These three stages take place simultaneously and continuously. From Fig. 1. The zone between the nip line of the delivery rollers and the twisted end of the yarn is called the spinning triangle [2] (Close up view of yarn formation in Fig. 1). In this zone the fibre assembly does not have any twist. The edge fibres slips out from this zone, and make little or no contribution to the yarn tenacity. Further, they lead to yarn hairiness. Ring spinning is a comparatively expensive process because of its slower production speeds and the additional processes (roving and winding) required for producing ring spun yarns [3].

Fig. 1: Ring yarn sequence system

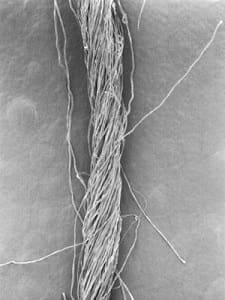

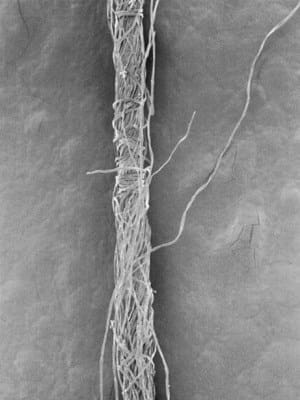

The Fig. 2 clearly state that yarn has a compact structure [2], with essentially no wrapper or hooked fibers. The self-locked structure is the result of intensive fiber migration, which in turn is influenced by the triangular geometry of the spinning zone and the high spinning tensions. The high axial strength of the yarn is the result of unique self-locked structure.

Fig. 2: SEM Image of ring spun yarn

3. Compact Spinning yarn

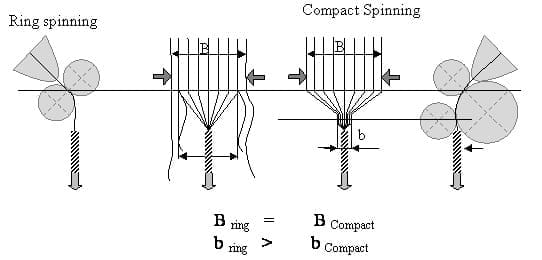

Compact spinning systems is almost similar to ring spinning system, only difference is spinning triangle of ring and compact spinning shown in Fig. 3. [3] The aim of the compact spinning is to improve yarn quality through narrowing the sliver leaving the drafting apparatus, before twisting it into yarn by condensing the twist triangle. The spinning triangle that occurs while the yarn is formed is the cause of many protruding fibres in the spun yarn. This causes greater waste of fibres, lower exploitation of fibre tenacity in the yarn poorer appearance and greater hairiness of the spun yarn [4]. Since the condensed spinning triangle is very small, the end breaks will be very less and therefore the fly liberation will also be less.

Fig. 3: Spinning triangle of ring and compact spinning systems

The compact yarn has different packing arrangement of fibres in the cross section as compared to conventional ring spun yarn as shown Fig. 4. In Compact yarn there are more regular fibres within the compact spun yarns. The arrangement of fibres in the compact yarn cross section showed a periphery-dense and core uniform packing. The distribution of twist angle implied a larger twisting efficiency. These findings provide evidence for the relatively larger strength, less hairiness and higher twisting efficiency of compact yarn [5]. Compact spun yarn has the some of the advantages like better imperfection values, high abrasion resistance, greater brilliance of colour and intensive dye penetration

Fig. 4: Structural view of compact spun yarn

4. Rotor Spinning

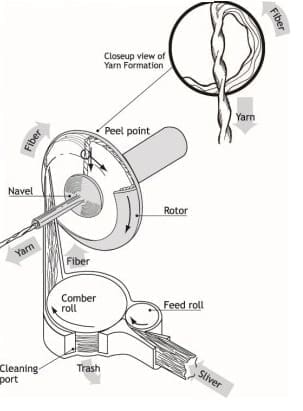

Rotor Spinning is a more recent method of yarn manufacture compared to the ring spinning. The process sequence of rotor yarn manufacturing is shown in the Fig. 5[2]. This is a form of open-end spinning where twist is introduced into the yarn without the need for package rotation. It allows in the form of slivers for higher twisting speeds with a relatively low power cost. In rotor spinning a continuous supply of fibres is delivered from delivery rollers off a drafting system or from an opening unit, before being sucked down through a delivery tube and deposited evenly in the groove of the rotor as a continuous ring of fibre. The fibre layer is stripped off the rotor groove are twisted together by the spinning action of the rotor, and the yarn is continuously drawn from the centre of the rotor. The resultant yarn is cleared of any defects and wound onto packages. The twist in the yarn being determined by the ratio of the rotational speed of the rotor and the linear speed of the yarn.

Fig. 5: Rotor yarn manufacturing

Fig. 6: Open end (Rotor) yarn Structure

The production rate of the rotor spinning is 6-8 times higher than that of the ring spinning and as the machine is fed directly by sliver and yarn is wound onto packages ready for use in fabric manufacture the cost of production of yarn is significantly cheaper. Rotor spun yarns are more even, however, somewhat weaker and have a harsher feel than ring spun yarns as shown in the Fig. 6 [2]. Rotor spun yarns are mainly produced in the medium count (30 Ne, 20 tex) to coarse count (10 Ne, 60 tex) range. Open-end yarns tend to be more uniform, lower in strength, more extensible, bulkier, more abrasion resistant and more absorbent [3].

5. Air jet Spun Yarn

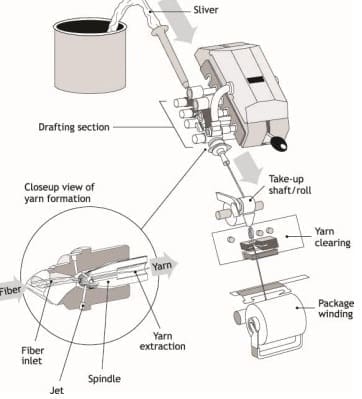

Air-jet spinning is a pneumatic method which consists of passing a drafted strand of fibers through one or two fluid nozzles located between the front roller of a drafting system and a take up a device as shown in the Fig. 7[2]. Look at the closed view of yarn formation in Fig. 7, air is injected into the two nozzles N1 and N2 at high pressures, which cause swirling air streams in opposite directions. Sliver is fed into the machine and is further drawn out to the final count and twist is inserted by means of a rotating vortex of high pressured air. The resultant yarn is cleared of any defects and wound onto packages ready for use in fabric formation.

Fig. 7: Air Jet yarn manufacturing

The air-jet spun yarn consists of an untwisted core of parallel fibers and a surface wrapping of fibers. The core fibers account for approximately 85-95% of the yarn mass. The surface wrapper fibers are helical in nature unlike the wrapper fibers in the rotor yarn. The wrapper fibers are not uniformly distributed over the length; sometimes they are few on the surface. Their frequency and tightness get influenced by the physical properties of the fibres and the spinning process parameters. The high level of constriction of the straight core fibers by the surface wrapper fibers results in high bending modulus of air-jet yarns. The drafting system S drafts the input material into a ribbon like form with parallel fibers [3].

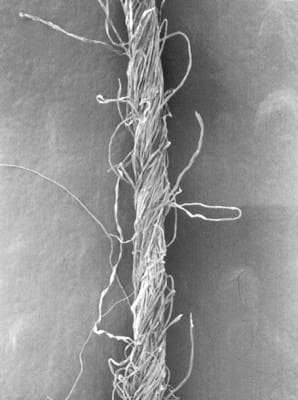

Fig. 8: Structure of Airjet Yarn

The SEM image of air jet yarn shows a high degree of similarity to the ring yarn structure as shown in the Fig. 8 [2]. As the yarn count gets finer, the yarn strength improves over the open end spun yarns of the same count. Vortex yarn is appropriate for medium to fine yarn counts. The softness of fabrics made from vortex spun yarns usually falls between similar open end and ring fabrics.

6. Structural representation of Spun yarns using different spinning system

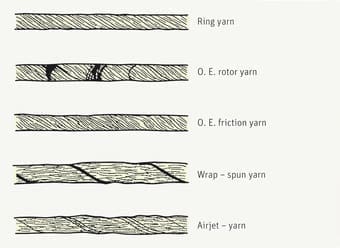

Fig. 9: Longitudinal view of yarn structure

The yarn structure mainly depends upon the raw material, fibre migration, twist and yarn type. The symmetrical representation of various spun yarn as shown in the Fig. 9 [6] Ring yarn has highest hairiness as compare to other unconventional yarn this because of the spinning triangle. The strength of the yarn mainly depends on fibre migration during yarn manufacturing. Ring spun yarn has the higher strength then the other spun yarn due to the fibre migration. The fibre packing density across the yarn cross-section is not uniform and that it is not highest at yarn core [7]. In compact spinning is a modified version of ring spinning, has drawn attraction of various researchers. In compact spinning, the fibre stream coming out of the drafting unit is condensed by means of pneumatic or any other mechanical compaction. As a result of this compaction, the structure of yarn changes along with its various characteristics. Due to the condensation of fibre flow, all the fibres lay close to each other and due to the absence of spinning triangle, all fibres are twisted to the yarn body [8]. The compact spinning yarn has the more uniform structure compared to the other spinning technique. The rotor spun yarn structures into seven classes based on scanning electron micrographs. Class I may be termed as ordered structure, because few, if any, outer zone fibres are present and the fibres are uniformly twisted. In class II, the loosely wrapped fibres are superimposed on the uniform structure of yarn core. Their wrapping angles differ from the twist angle of the core fibres and vary along the yarn length. In class III, the outer zone fibres are loosely attached to the yarn and appear entangled. They give a hairy appearance to the surface structure. Class IV may be termed as multiple wrapped, because parts of the wrapping fibres are lightly coiled around the core, whereas their remainders adopt lower wrapping angles. In class V, the outer zone fibres have an opposing helix to the twist helix of the core fibres, and their wrap angle can be up to 75̊. In the case of Class VI, the surface fibre appears tightly and closely wrapped around the core. These sections of yarn look uniform and have no protruding fibre ends or loops. The angle of wrap is approximately 90 degree. In class VII, one or two fibre appears tightly wrapped around the core at an angle of 90 degree, forming a belt shape owing to the locally concentrated winding[9]. The airjet spun yarn consisted of an untwisted core of fibres and a surface layer of fibres wrapped around the greater part of the core. They classified the yarn into three types with respect to the yarn structure [10]. The airjet yarn has two parts bundles fibres and outside wrapping fibres constitute the yarn. In the bundle fibres, a majority of the fibres are inclined at an angle of 5 to 10 degree in ‘S’ and ‘Z’ directions. Sometimes the fibres are parrlel to each other or crossed together. The outside wrapping fibres are gripped on the bundle fibres in different styles, such as a corkscrew like wrapping, irregular wrapping, linked wrapping, even wrapping featuring the edge free and fibres wrapped evenly on the bundles, loose wrapping and non-wrapped portions [11].

7. Colour Evaluation of Textiles

An organization called CIE (Commission Internationale de l’Eclairage) has determined the standard values that are used worldwide to measure colour. The values used by CIE are called L*, a* and b* and the colour measurement method is called CIELAB. L* represents the difference between light (where L*=100) and dark (where L*=0). A* represents the difference between green (-a*) and red (+a*), and b* represents the difference between yellow (+b*) and blue (-b*). Using this system, any colour can be made to correspond to a place on the graph shown in Fig 10. Variables of L*, a*, b* or E* are represented as delta L*, delta a*, delta b* or delta E*, where delta E* = delta (delta L*2+delta a*2+delta b*2). E* represents the magnitude of the difference in colour, but it does not indicate the direction of the colour difference.

Fig. 10: CIELAB coordinate system

Munsell, is another commonly used colour measurement system. Munsell aimed to create a rational way to describe colour that would use clear decimal notation rather than colour names. Munsell modelled the system as an orb around whose equator runs a band of colours as shown in the Fig. 11. The axis of the orb is a scale of neutral grey values with white as the North Pole, and black as the South Pole. Extending horizontally from the axis at each grey value is a gradation of colour progressing from neutral grey to full saturation. With these three defining aspects, any of thousands of colours could be fully described. Munsell named these aspect, or qualities as hue, value, and chroma.

Fig. 11: The Munsell System

1 Hue

Munsell defined hue as the quality by which we distinguish one colour from the another. He selected five principle colours: red, yellow, green, blue, and purple and five intermediate colours: yellow-red, green-yellow, blue-green, purple-blue, and red-purple. He arranged these in a wheel measured off in 100 compass points. The colours were identified as R for red, YR for red-yellow, Y for yellow etc. Each primary and intermediate colour was allotted ten degrees around the compass, and then further identified by its place in the segment.

7.2 Value

Munsell defined ‘value’ as the quality by which we determine light colours from dark ones. Value is a neutral axis that refers to the grey level of the colour, ranging from white to black.

7.4 Chroma

Chroma is the quality that distinguishes a pure hue from a grey shade. The chroma axis extends from the value axis at a right angle and the amount of chroma is noted after the value is assigned. Therefore, 7.5YR 7/12 indicates a yellow-red hue tending toward yellow with a value of 7 and a chroma of 12. However, chroma is not uniform for every hue at every value. Mussel saw that full chroma for individual hues might be achieved at different places in the colour sphere. In the Munsell System, reds, blues, and purples tend to be stronger hues that average higher chroma values at full saturation, while yellows and greens are weaker hues that average fullest chroma saturation relatively close to the neutral axis[12].

8. Influence of yarn structure on dyeing

The yarn structure has significant influence on the dyeing behaviour of the textile materials. Mehmet et al. stated that [13], The lightness values (L* ) of fabrics from both single and plied compact yarns were lower than those of the fabrics from ring yarns. This could be attributed to the lower cover factor of a compact yarn fabric. In general the lightness values (L* ) of fabric made from plied yarns greater than the fabrics from single yarns due to higher cover factor. The comparison of Chroma values (C*) and colour strength values (K/C), fabrics from compact yarns had higher than those of ring spun yarns. Compact yarn fabric could be dyed with more saturation. The colour values of single yarns were higher than the plied yarns. Dyeing efficiency of compact yarn was reported higher than the ring yarn, This seems beneficial in terms of reducing the costs of dyeing, as less dye might be used for dyeing fabrics of compact yarns to reach the same shade depth of fabrics made from ring yarns. The changes in K/S values of fabrics made from single yarns were greater than the fabric made form plied yarns. In abrasion test, the fabrics from compact yarns yield higher K/S values than those of the fabrics from ring yarns. The single or plied fabric from compact yarn had lower colour differences (∆E*ab) than the fabrics from ring yarns. Behcet et al.[14] report suggested that the greater K/S values of dyed ring fabrics as compared to dyed compact fabrics indicate that light absorption at ʎmax was greater for dyed ring fabrics. The colour differences (∆E*ab) increased as the yarn count decreased. Fibre and yarn alignment together with fabric cover and bulkiness affected the dye sorption. The light reflectance properties of the both compact and ring yarn fabric was different. Ortlet et al.[15] stated that, lower the hairiness value, the smoother is the surface of yarns. The hairiness value of vortex spun yarn is lower than those of ring and rotor yarns. The surface of vortex spun yarn reflects light more than ring spun and rotor spun yarns. Consequently a % R value of vortex spun yarn is higher than the ring and rotor yarn.

9. Influences of fabric structure on dyeing

Ahmet et al.[16] stated that the warp and weft density and fabric porosity affects the dyeing behaviour. The main problem in dyehouses is caused due to differences between the structural parameters of the reference fabric of which the dyeing recipe is known and the fabric to be dyed. Fabric structure would lead to different liquor flow interactions through the fabrics. In such a case, if the dyeing recipe of a loose fabric is applied to a dense fabric, the final colour obtained would be different. Fluid flow through textiles is a complex physical phenomenon, because of the fibrous and highly non-uniform organisation of the structure and deformation. Nevertheless, fluid flow through a fabric is important in order to understand many of its physical and mechanical properties. In a fabric, pores are situated in the fibres, between fibres in the yarns, and between yarns in the fabrics. When considering fluid flow through textiles, the shape arrangement and size distribution of voids through which the fluid flows are of greater importance. The smaller the pore dimensions, the grater the resistance to the dye liquor flow. Therefore decreased porosity leads to a decrease in the fluid volume passing through the fabric.

The researcher stated that increasing weft density, the colour yields of the samples decrease. The relation between fabric density and colour yield was investi¬gated by correlation analysis with the significance value (α) of 0.05. The results showed that the colour yield change caused by weft density variation is statistically sig¬nificant for all shades. On the other hand, the effect of warp yarn density variation is statistically insignificant. The low¬est colour yield change occurred in the samples dyed with Remazol Yellow RR. This is because the L* value of the yel¬low colour is the highest (i.e. the lightest and brightest). The increased dyestuff concentration leads to an insignificant change in the yellow colour when com¬pared to the red or blue colours. Another important point is that the colour yield change is more significant in dyed sam¬ples with 2% dye concentration. In 0.5% dyeing, the dye liquor contains a lower amount of dyestuffs, thus there are no excess dyestuffs for the loose fabrics to take up. On the other hand, by in¬creasing the dye concentration, loose fab¬rics can take up more dyestuffs compared to dense fabrics.

As for the researcher, higher the po¬rosity of the fabrics, the higher the colour yields. This increase is more significant in dark shades. For dense fabrics, the resistance to liquor flow is higher than loose fabrics. The liquor penetra¬tion into the fabric is more difficult. Pore area can also be taken as a factor that affects colour yield along with porosity, because fabrics with the same porosity can have different pore dimensions. For instance, considering two fabrics with the same porosity, fabrics produced using fine yarns have larger pores when compared to fabrics produced using coarse yarns.

The effect of pore dimensions on the colour yields of the dyed fabrics This increase is more significant in dark shade dyeing. In this study, the effects of porosity and pore area on colour yield are analogous because there is no differ¬ence between the yarn linear densities. It was observed that the effects of porosity and pore dimensions of the samples on the L* values of the dyed fabrics are stronger than the effects on a* and b* values. A correlation analysis was carried out (α=0.05) in order to investigate the effects of porosity and pore dimensions on colour yield. It was observed that colour yield change due to the above factors is statistically significant.

The surface texture effect on visual and instrumental colour evaluations is compared to the standard sample (jersey) and using the gray scale method, the twill-pique and interlock pairs had the highest and lowest visual colour differences in the six colour centres, ranging from 1.22-1.44 and from 0.51-0.60 CIEDE2000 units respectively. The visual colour difference for each texture pair was also influenced by the colorimetric values of textured samples. Among all six colour centres, the pink and the red samples showed the widest and narrowest spread of visual colour difference distribution. The instrumental results show that the colour differences were attributable to lightness, chroma, and hue differences. By comparing the instrumental and visual colour difference evaluations, it was found that there was poor consistency between them, with a mean PFi3 value of 35.8. The agreement was lowest in the case of the lacoste sample pairs, which had the largest PFi 3 value (62.5). This inconsistence suggests that the effect of texture needs to be considered in the colour difference evaluation of textile samples and that the conventional way of using spectrophotometric measurement and colour difference equations are not adequate to describe the visual colour difference of textured fabrics [17].

10. Conclusion

Yarn properties mainly depend on fibre properties and spinning system. Yarn produced by different spinning systems show different characteristics. When compared to all spinning systems compact yarn has the low hairiness, smooth surface, compact structure and excellent physical property. Many researchers considered the structure and properties of yarn has been significantly affected the dyeing behaviour of the materials. The K/S values, L* and E* values of the textile materials mainly depends on the yarn properties such as count, ply variation, type of yarn and fabric properties such as warp density, weft density, porosity of fabric. The researchers found the dye uptake of the materials due to the higher for loose structure yarns and lower for compact structure yarn. Similarly the fabric dye uptake also greater for less weft dense fabric then the high dense fabrics.

11. Reference

1. Eric oxtoby, ‘Spun yarn Technology’ Butterworth & Co (Publishers) Ltd (1987). ISBN:0-408-01464-4

2. https://www.intracen.org/cotton-guide/cotton-value-addition-yarn-formation/

3. https://www.textileschool.com/School/Spinning/RingSpinning.aspx

4. Momir Nikolic, Zoran Stjepanovic, Franc Lesjak and Andrej Stritof, ‘Compact Spinning for Improved quality of Ring-spun yarns’ Fibres & Textiles in Eastern Europe, (2003), Vol. 11, pp.30-35

5. Hui wu, Meiyu Chen, Wei wang, Kan lai and Buhu ma, ‘ The Structure of Compact Yarn’ Textile Research Journal, Vol. 79(9), pp. 810-814

6. https://www.rieter.com

7. Ishtiaque S M, Indian J Fibre Text Res, (1986), Vol. 11, pp. 208

8. Dash J R, Ishtiaque S M and Alagirusamy R, Indian J Fibre Text Res. (2002), Vol.27, pp. 362

9. Lawrence C A and Finikopulos E, Indian J Fibre Text Res. (1992), Vol.17, pp.201

10. Lawrence C A and Baqui M A, Text Res J, (1991), Vol. 61(3), pp.123

11. How Y L, Cheng K and Wong S, Text Asia, (1991), Vol. 22(11), pp.51

12. https://www.specialchem4coatings.com/tc/color-handbook/index.aspx?id=cielab

13. Mehmet ozturk and Banu uygun nergis, ‘Determination the dependence of colour values on yarn strcuture’ Coloration Technology, (2008), Vol. 124, pp.145-150

14. Behcet becerir and sunay omeroglu, ‘ Comparison of colour values of plain cotton fabrics knitted from ring and compact spun yarns’ AATCC review, (July 2007), pp. 41-44

15. Ortlek H G, Tutak M and Yolacan G, ‘Assessing colour differences of viscose fabrics knitted from vortex, ring and open end rotor spun yarns after abrasion’ The journal of the Textile Institute, (2010), Vol. 101, No. 4, pp. 310-314

16. Ahmet cay, Riza Atav and Kerim duran, ‘Effects of warp-weft desity variation and fabric porosity of the cotton fabrics on their colour in reactive dyeing’ Fibres & Textiles in Eastern Europe, Vol. 15, no. 1, pp. 91-94

17. Shao Sijie and John H. Xin, ‘The effect of Texture structure on instrumental and visual color difference evaluation’ AATCC Review, (October 2006), pp. 42-47.