IMPACT ON ROTOR & AIR-JET YARN PROPERTIES DUE TO COMPONENTS AND PARAMETER

Nitin. T. Patil

Veermata Jijabai Technological Institute (VJTI), Mumbai

Prof Dr. S. P. Borkar

Veermata Jijabai Technological Institute (VJTI), Mumbai

Dr. Stephan Weidner-Bohnenberger

RIETER Machine Works Ltd.

Marc Schnell

RIETER Machine Works Ltd.

Abstract

Today Ring, Rotor and Air-jet spinning system are commercially used for yarn production. Each spinning technology creates a typical yarn structure. This yarn structure determines the characteristics of the yarn itself, the characteristics in downstream processing and finally of the subsequent textile product. Textile fabrics with the

softest touch can be undoubtedly produced from combed ring yarn. In order to manufacture a soft rotor yarn, the twist factor must be set low and supportive measures need to be undertaken in textile finishing. Rotor spinning has a great potential to reduce the twist factor, which is the basic prerequisite for the production of knitted fabric with a soft touch; by support of a new spin box generation and its components. Similarly the air-jet spinning system is now moving from 100% CV into new applications like CO blends and 100% CO combed for knitting. The challenge is to compete the softness of a conventional ring yarn. The main objective of this study is to compare the effect of twist level, spinning components, process parameters on yarn properties such as yarn packing density which will support in improving the fabric hand for Rotor and Air-jet yarn.The other objective of this study is to check the impact on strength and elongation due to reducing the twist.

Keywords: Ring spinning, Rotor Spinning, Air-jet spinning, New spinning geometry, Yarn properties, Yarn packing density, Yarn diameter

1 Introduction

The yarn structure is dependent primarily upon the raw material, spinning process, spinning principal, machine settings, twist, etc. The structure can be voluminous or compact, high or low hairiness; soft or hard; round or flat.

Yarn structure has a greater or lesser influence on Hand, Strength and Elongation, Resistance to abrasion and Dye absorption.

Rotor and Air-Jet yarn compare to ring spinning, offer the advantages such as High production rates, Elimination of processing stages, Considerable reduction in personnel and space and energy consumption and relative ease of automation.

On other side, Yarns produced from new spinning systems like rotor and air-jet spinning have harsher feel compared to ring spun yarn due to the different outer structure of the yarn. With the proper selection of raw material, spinning components and machinery setting, now it would be possible to compensate in order to improve softness even on new spinning systems. With this the gap between new spinning system and ring spun yarn can be narrowed down without compromising the parent benefits like better abrasion and pilling resistance of Rotor and Air jet spun yarn respectively.

1.1. Ring spinning

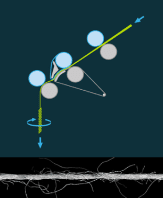

In ring spinning, the fibre mass in cross section of the roving is reduced by a drafting unit. The twist inserted by the turning spindle moves back and reaches the fibres leaving the drafting unit. The ring yarn process is characterized by high flexibility in the use of the raw

material, the yarn count and the yarn character. Ring yarn possesses a high degree of strength and yarn hairiness. [10]

1.2. Rotor Spinning

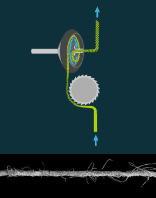

In rotor spinning, the input fibre strand is a drawn sliver. A sliver may have more than 20,000 fibres in its cross section. This means that a yarn of 100 fibres per cross section will require a total draft of 200. This amount of draft is substantially higher than that applied in ring spinning. The separated fibres are fed into the turning rotor by an air stream. The fibres are collected in the rotor groove and collected from there by the rotating open yarn end and bound in by twisting. The yarn then is pulled out of the spin box via the nozzle. Loose fibres in this moment are wrapped around the yarn, resulting in the characteristic wrapper fibres or “belly belt fibres” on the surface of the yarn. Depending on the shape of the rotor groove the yarn shape results more or less compact. The higher the centrifugal force due to rotor speed and rotor diameter, the yarn needs to be stronger and has less elongation.[10]

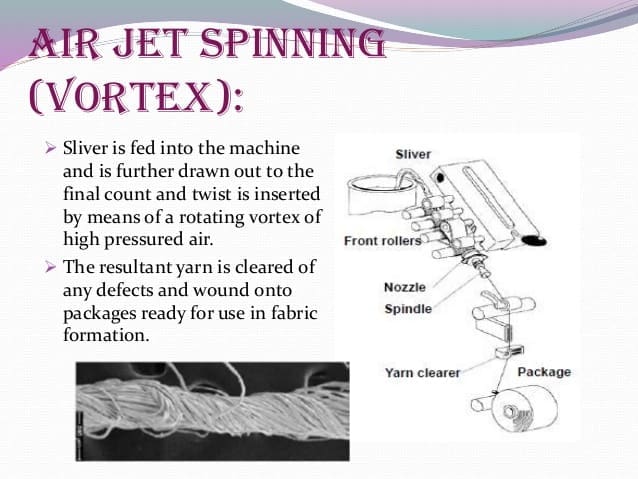

1.3. Air-jet Spinning

In Air- jet spinning, a sliver is fed to the drafting system; the drafted sliver enters a spinning nozzle. The leading end of the fibres forms the parallel yarn core; the free fibre ends are wound around the yarn core by the air in the spinning nozzle. The Air- jet yarn is then wound onto a package. The air-jet-spun yarn structure consists of core fibres without significant twist and covering fibres with a genuine twist, which ultimately produces the corresponding yarn tenacity. The specific yarn structure results in yarn tenacity between that of a ring-spun yarn and that of a rotor-spun yarn.[10]

2. Part I – Rotor spun yarn

The study is carried out on rotor yarn with same material ,same count and same conditions

2.1. Latest Rotor Spin Box Technology

The possibility to reduce twist in spinning is limited by the spinning stability. The cohesion of fibres gets less with reduced twist, so that the spinning process gets interrupted by a yarn break more and more frequently resulting in loss of efficiency of the process.

The newest spin box technology applied for the trials in this respect allowed additional twist reduction compared to older technologies, which are still present in the market.

This better spinning stability is due to:

Reduced spinning tension thanks to latest spin box

Ring Spinning

|

– Most flexible in raw – Material and count – High tenacity – High hairiness |

Rotor Spinning

|

-High optical evenness – Low variation in tenacity – Designable hairiness – High abrasion resistance – High volume |

Air-jet Spinning

|

– Unique low hairiness – High volume – Low tendency for staff – High abrasion resistance |

|

Fig.1. Characteristics of the yarns produced from different spinning system |

- geometry, new TWISTstop arrangement.

- Lower spinning tension allows to reduce possible twist multiplier

- With the correct spinning component it is possible to produce soft yarn

- TWISTstop insert with 3 twist-retaining bars for high twist-retaining effect

- High spinning stability

Effect of twist reduction

- Less twist typically results in softer yarn

- Less twist at same rotor speed results in higher productivity

- Evenness and count variation gets better, as well as the imperfections

3. Rotor yarn properties evaluation

The basic study is conducted with Ne 30’s cotton yarn with different twist levels to see the impact on physical yarn properties such as yarn strength, elongation, yarn hairiness and yarn packing density.

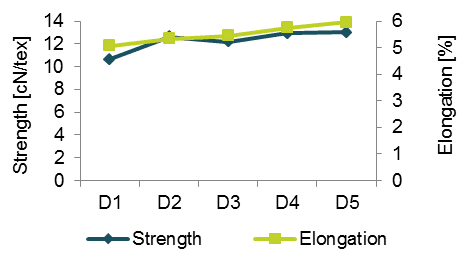

3.1. Yarn strength and elongation

Graph 4.1 Strength-Elongation

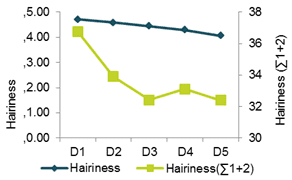

3.2. Yarn hairiness |

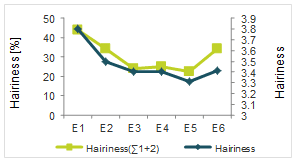

Graph 4.2: Hairiness Curve

In rotor spinning, the yarn hairiness can be designed by means of a wide range of spinning elements like rotor groove and draw-off nozzle. It has been verified during this study that today with latest spin box there is the possibility to produce yarn with a lower twist multiplier without affecting spinning stability.

| Table 2. Machine parameter influences softness of yarn | |||||

| Sample | D1 | D2 | D3 | D4 | D5 |

| Alpha [αe.]/αm | (3.2) 97 | (3.6) 109 | (4.0) 121 | (4.5) 136 | (5.0) 151 |

| Delivery [m/min] | 162 | 144 | 130 | 115 | 104 |

| T/M | 693 | 778 | 864 | 971 | 1078 |

| Strength [cN/tex] | 10.63 | 11.41 | 12.17 | 12.92 | 13.00 |

| Elongation [%] | 5.08 | 5.31 | 5.45 | 5.75 | 5.95 |

| USTER CV% | 16.05 | 15.95 | 16.03 | 15.74 | 15.84 |

| USTER Hairiness | 4.71 | 4.59 | 4.44 | 4.29 | 4.06 |

| Package Density g/cm3 | 0.4 | 0.41 | 0.43 | 0.45 | 0.47 |

| Table 4. Statistical test for rotor yarn properties | |||

| Test | Analysis | Yarn (D1 to D5) | Significance |

| Strength cN/tex | MS | 4.74 | |

| F | 48.76 | ||

| P- value | 0.000** | Significant | |

| F crit | 2.866 | ||

| Elongation % | MS | 0.59 | |

| F | 8.61 | Significant | |

| P- value | 0.000** | ||

| F crit | 2.86 | ||

| CVm % | MS | 0.0841 | |

| F | 4.711 | Significant | |

| P- value | 0.000** | ||

| F crit | 2.86 | ||

| Neps | MS | 32210.06 | |

| F | 7.30 | Significant | |

| P- value | 0.000** | ||

| F crit | 2.86 | ||

| Hairiness | MS | 0.31 | |

| F | 118.89 | Significant | |

| P- value | 0.000** | ||

| F crit | 2.86 | ||

| Diameter | MS | 0.000315 | |

| F | 366.58 | Significant | |

| P- value | 0.000** | ||

| F crit | 2.866 | ||

| Yarn package Density | MS | 0.004056 | |

| F | 289.71 | Significant | |

| P-value | 0.000** | ||

| F crit | 2.866 | ||

| ** Significance at (0.05) | |||

Graph 4.3: Rotor yarn packing density and Diameter

3.3. Yarn packing density and diameter |

The packing density, i.e. the fiber distribution in a yarn cross section, can significantly influence the properties and

quality of the yarn. Thus, the need for precise and concise information about packing density becomes a must for an in-depth understanding of yarn structure and hence yarn mechanics. However from graph 4.3 it is also clear that twist factor is responsible for packing density changes. For a given yarn count, fibers in the yarn with a higher twist factor are distributed in less scattered way, and the peak of packing density curves will shift towards the yarn axis. Similar impact has been observed with diameter change:

Increased twist results in increased yarn density and reduced yarn diameter.

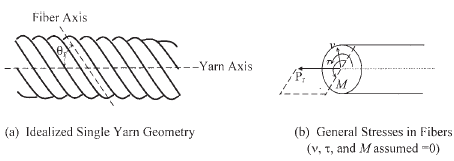

During the twisting process, an external uniaxial tensile load P along the axis of yarn must exist, since twisting cannot process without tension. This tensile load can be conveyed to the constituent fibers of the yarn. Assuming that the fibers are perfectly flexible members, incapable of resisting any axial compressive forces, the stresses M (a bending moment), V (shear force) and T (a torsional moment), will all vanish. Therefore, the only fiber force that needs to be considered is the tension acting in the direction parallel to the fiber axis Pr. Since the individual contribution of Pr to the total load Pc in compression is where, m is the total amount of fibers in the yarn cross section. Equation 2 states that if the axis tension carried by each fiber is multiplied by the sine of the helix angle of the fiber and all such products are summed. The total will represent the compression load acting on the yarn in the direction normal to the yarn axis. Apparently, the higher the twist level, the higher the helix angle Φ and in turn the more prominent the compressive load. This is how a more compact yarn structure is created. [26][27].

Fig.3. Stress analysis of fibers in spun yarn

P per fiber = Pr sinΦ r (1)

Where, Φr is the fiber helix angle.

Therefore the total load Pc can be calculated Pc = (2)

4. Part 2: AIR JET SPINNING

2 Role of Spinning Systems in improving softness

Yarns produced from new spinning systems like air-jet have harsher feel as compared to ring spun yarn due to their different outer structure. With the proper selection of raw material, spinning components and machinery setting, now it would be possible to compensate in order to improve softness even on new spinning systems. With this, the gap between new spinning system and ring spun yarn can be narrowed down without compromising the parent benefits like better abrasion and pilling resistance of Air-jet spun yarn.[10][17][20]

2.1 Development of Soft Yarn

Softness is an important characteristic for those products which come directly in contact with skin .Ways to produce soft yarns.

- Raw material i.e. to use fine fibres.

- Process parameters i.e. spinning under lesser tension.

- Incorporation of low twist & plying.

- Production hollow yarns using polyvinyl alcohol (PVA) fibers.

Selection of right spinning technology (ring, rotor, Air-jet) [10][2].

2.2 Improvement in Softness during Spinning

- To improve softness of air-jet yarn with modified yarn structure with newly developed components and process parameter

- To improve fabric feels of air-jet yarn by chemical finishing e.g. Softeners to match with Ring.

Comparative analysis of yarns, fabrics and garments with different subjective and objective tests

| Table 1. Machine parameter influences softness of yarn | |||||||

| Sample | E1 | E2 | E3 | E4 | E5 | E6 | |

| Machine | J 20 | J 20 | J 20 | J 20 | J 20 | J 20 | |

| Yarn [Ne]/Nm | 30/51 | 30/51 | 30/51 | 30/51 | 3/51 | 30/51 | |

| Delivery [m/min] | 460 | 420 | 380 | 340 | 380 | 380 | |

| Spin Tip in mm | 0.9 | 0.9 | 0.9 | 0.9 | 0.9 | 1.0 | |

| Air pressure

Strength [cN/tex] |

4.3

11.7 |

4.3

13.4 |

4.3

14.8 |

4.3

15.4 |

6.0

15.6 |

6.0

15.5 |

|

| Elongation [%] | 5.1 | 5.5 | 6.0 | 6.3 | 6.2 | 6.2 | |

| USTER CV% | 13.9 | 13.8 | 14.3 | 14.3 | 14.4 | 14.1 | |

| USTER (H%) | 3.8 | 3.5 | 3.4 | 3.4 | 3.3 | 3.4 | |

| Packing density | 0.44 | 0.46 | 0.48 | 0.50 | 0.52 | 0.51 | |

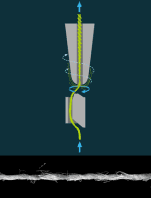

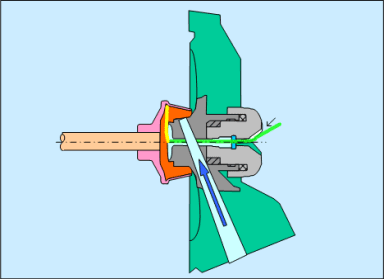

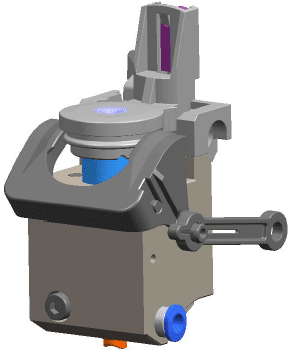

2.3 Spin Nozzle Housing

The spin nozzle is the heart of the air-jet spinning technology. The bottom part of the spin nozzle consists of a fiber-feeding element (FFE), to which a drafted and condensed sliver is delivered. The prepared sliver is spun into yarn due to the effect of pressurized air inside the spinning nozzle. In the nozzle housing there is a twist element with holes through which pressurized air is supplied at a volume equal to that of the diameter of the spin air holes and air pressure. Air is discharged at an angle to generate a whirl wind. Fibres are fed through the spin tip with the diameter of nozzle. Air rotates around the spin tip and creates a twist in the fibres. [10][20]

Fig. 3 Spin nozzle housing

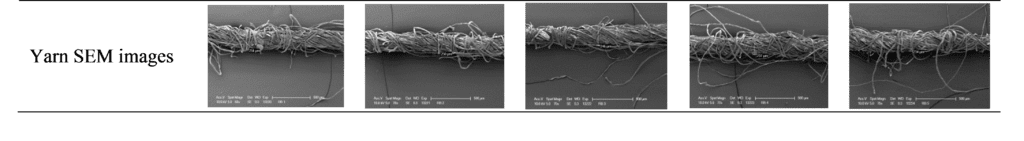

3. Air-jet Yarn Properties Evaluation

The basic study is conducted with Ne 30’s cotton yarn with different twist levels to see the impact on physical yarn properties such as yarn strength, elongation, yarn hairiness and yarn packing density and influencing together the softness of the yarns. [31][1][9]

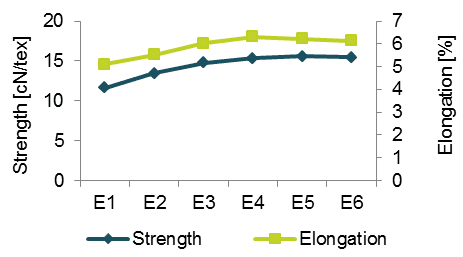

3.1 Yarn Strength and Elongation

Table 1 is an overview of the different trials to improve the softness of the air-jet yarns. Different delivery speeds, different air pressure and spin tip diameter influencing the yarn properties. E5 and E6 with low delivery speed and high air pressure results in highest yarn strength and elongation. The yarn packing density is also on the high side. [31][9]

3.1Strength & Elongation

Graph 4.1 Strength & Elongation curve

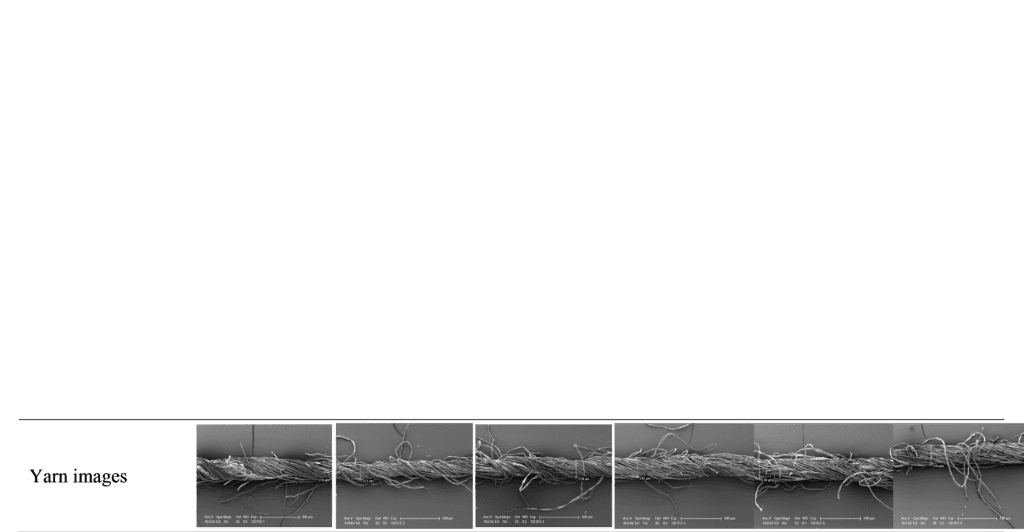

Graph 4.2: Hairiness Curve

From table 1 and graph 4.1 shows effect of delivery speed and air pressure (influencing twist level) on air-jet yarn. Lower speed and/or higher air pressure increases simultaneously elongation and strength due to the higher twist effect on the yarn. On the other hand; graph 4.2 shows the influence on hairiness of yarn at the same time. The soft feel of fabric can be better if ∑1+2 hairiness value is higher. Low twist causes more hairiness in the yarn due to the open structure, visible as well in the yarn packing density. [31]

3.2 Yarn Hairiness

However, low hairiness is a drawback where a large number of protruding fiber ends contribute to a soft hand. First of all, air-jet spun yarns can now be produced with significantly lower twist multipliers than previously, without any adverse effect on spinning stability. [31][8]

| Table 3. Statistical results for Air-jet yarn properties | |||

| Test | Analysis | Yarn (E1to E6) | Significance |

| Strength cN/tex | MS | 12.03 | |

| F | 2178.15 | Significant | |

| P- value | 0.000 | ||

| F crit | 2.62 | ||

| Elongation % | MS | 1.10 | |

| F | 539.72 | Significant | |

| P- value | 0.000 | ||

| F crit | 2.62 | ||

| CVm % | MS | 0.34 | |

| F | 2.40 | Not | |

| P- value | 0.066 | Significant | |

| F crit | 2.62 | ||

| Neps | MS | 18764.12 | |

| F | 72.73 | Significant | |

| P- value | 0.000 | ||

| F crit | 2.62 | ||

| Hairiness | MS | 0.1200 | |

| F | 11.39 | Significant | |

| P- value | 0.000 | ||

| F crit | 2.62 | ||

| Diameter | MS | 0.0007 | |

| F | 117.76 | Significant | |

| P- value | 0.000 | ||

| F crit | 2.62 | ||

| Yarn packing Density | MS | 0.0041 | |

| F | 130.9 | Significant | |

| P-value | 0.000 | ||

| F crit | 2.62 | ||

| ** Significant at (0.05) | |||

3.3 Air-jet Yarn Packing Density &Diameter The impact of air pressure ,delivery speed and spin tip is visible on yarn packing density and yarn diameter .Factors affecting real yarn diameter are essentially those that affect yarn density or fibre compactness. In general yarn become softer as the density become lower and diameter become higher keeping material and process same.

Graph 4.3: Air-jet yarn packing density and diameter

Conclusion:

An enumeration of various research revealed that all the studies were interested in the improving the fabric hand for rotor and air-jet yarn .The objective of this work is to validate and analyses the impact on the yarn packing density and yarn diameter of rotor and air-jet yarns with determining the more influential intrinsic yarn parameters like strength, elongation etc . In this study, the authors provided a base to carry out further investigation in knitted fabric for fabric hand due to spinning and processing . The twist increase results in a free air volume reduction hence proportionally impact yarn packing density .A statistical study allowed the authors, by using ANOVA test to retain the most influential factors in the yarn packing density, the yarn count and the twist in yarn by keeping the strength and elongation at practical acceptable level as per requirement of downstream process .

References

- Anindya Ghosh, ‘Studies on structural aspects of ring, rotor Air-jet and open-end friction spun yarns’ National conference on Emerging trends in textile, fiber & apparel engineering, Govt. college of engineering, Berhampore, West Bengal, March 200 6.

- Rameshkumar C., et. al., Comparative studies on ring rotor and vortex yarn knitted fabrics, AUTEX Research Journal, Vol. 8, No4, December 2008.

- Zhuan Yong Zou, A Study of Generating Yarn Thin Places of Murata Vortex Spinning, Textile Research Journal 2009 79: 129.

- Guldemet Basal, vortex spun yarn vs. Air-jet spun yarn, AUTEX Research Journal, Vol. 3, No3, September 2003.

- Huseyin Gazi Ortlek and Levent Onal, Comparative Study on the Characteristics of Knitted Fabrics Made of Vortex-Spun Viscose Yarns, Fibers and Polymers 2008, Vol.9, No.2, 194-199.

- Rieter Com4 Yarns*

- Carl Lawrence, Fundamentals of Spun Yarn Technology

- Klein, New Spinning System, Vol., 5, The Textile institute, First Edition, 1999.

- K. Sinha and Tanveer Malik, A Study to Reduce the Stiffness of Air Vortex Yarn, Department of Textile Technology, Shri Vaishnav Institude of Technology and Science

- W.S.Hearle, P.Grosberg, S.Backer, Structural Mechanics of Fiber , Yarns, and Fabrics, Department of Textile Technology, The

- Y. Jiang, J. L. Hu, K. P.S. Cheng and R. Postle, Determining the Cross-Sectional Packing Density of Rotor Spun Yarns, Textile Research Journal 2005, 75, 233

- Chandramouli, kumaraguru college of Technology, An investigation of Air Vortex Yarn with Different Blend Proportion, Journal of the Textile Association, March-April 2012, page. 376-371.

- Arindam Basu, Yarn structure – properties relationship, The South India Textile Reserch Association, coimbatore 641 014, India

- G K Tyagi and S Shaw, Structural and characteristic variations in viscose ring- and air-jet spun yarns as a consequence of draw frame speed and its preparatory process, The Technological Institute of Textile & Science Bhiwani 127 021, India. Received 15 November 2010; revised received and accepted 3 February 2011.