In modern times with emerging contribution of Technical Textiles in all spheres of human life, the Geo-textiles have opened up new areas in civil engineering. The technology is gradually upgrading and regions which were earlier unworkable are now being developed. However, in some applications like Geo-textile Encased Columns for construction of roads in extremely soft soils where tubular structure of the fabric is formed by stitching; the seams due to its lower strength and different fabric properties have become a major concern for its implementation in real structures as it adversely affects the structure. Due to which there has been limited development in this field. In this backdrop an affordable and locally available High Strength technical seamless circular fabric from high tensile strength synthetic yarns developed using simple circular weaving technology will be ideal for such and other applications where circular Geo-textile is required especially for Indian sub-region.

Authors:

Dr. U.K Gangopadhyay, Executive Director, SASMIRA & Sanjay Saini, Scientist D, SASMIRA The Synthetic & Art Silk Mills Research Association [SASMIRA], Worli, Mumbai-400030

Introduction:

One of the sectors of textile industry that has received significant attention across the world is Technical Textiles. Technical Textiles are defined as textile materials and products used primarily for their technical performance and functional properties. Unlike conventional textiles where aesthetic value is one of the key usage considerations, Technical Textiles are used on account of their specific physical and functional properties. Technical Textiles are used individually as a stand-alone product, or as a component/part of another product to improve the performance of the product. Technical Textiles are also referred to as industrial textiles, functional textiles, performance textiles or engineering textiles.

Technical Textile has become a major segment globally because of several advantages like functional requirement, health and safety, cost effectiveness, durability, high strength etc. It is a large and growing sector and supports a vast array of other industries. The global growth rates of technical textiles are about 4% per year greater than the growth of home and apparel textiles, which are growing at a rate of 1% per year.

Technical textiles are segregated into 12 major segments:

In recent times Geo-textile Encased Columns have become most sought after technology the world over for construction of civil structures on soft grounds. However, for this structures tubular fabric is required [Figure1-Geo-textile Encase Columns [GEC] for construction of roads in soft soils].The advantages of tubular Geo-textiles, drawback of present circular fabric structure, the new seamless Circular fabric development and its benefits is discussed here.

A. Geo-textile Encase Columns

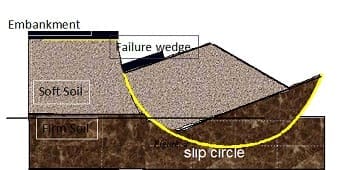

Large areas of India are covered with soft clay deposits, especially coastal regions. As a result of economic growth, many infrastructure projects, such as roadway embankments, are being constructed in areas with weak soil deposits. Many challenging problems have been encountered with regard to construction on soft soil deposits including bearing capacity issues, excessive deformation, and slope instability. The instability or deep-seated failure of a roadway embankment constructed on a soft foundation has become a serious issue for geotechnical engineers. Several ground improvement techniques have been widely implemented to avoid deep-seated failures in weak soils including sand compaction columns, stone columns, and deep mixed columns. The problems due to soft soils are low bearing capacity, excessive settlement and deep seated foundation failure [Figure 2]

The stone column, or granular pile technique, has been widely adopted to improve the soft soils through the inclusion of granular columns which have a stiffness and drainage capability that is far higher than those of the surrounding weak soil. In addition to the above benefits, this technique is characterized by the ease of construction. Stone columns have been widely used since 1970s to strengthen a foundation soil carrying heavy ironworks.

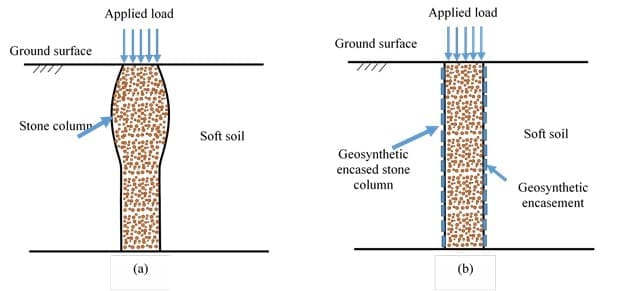

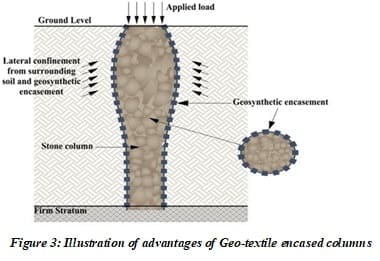

Since a stone column (see Figure 3a)) derives its bearing capacity from the passive resistance offered by the native surrounding soil, the inclusion of stone columns in very soft soils may not be sufficient to the desired level of improvement. When embedded in soft clay, stone columns may bulge due to lack of confinement offered by the surrounding soft soil. Furthermore, the soft clay may enter the voids between granular material of column to cause clogging and reduce the permeability of granular columns for drainage.

Therefore, Geo-textile encased stone columns (as shown in Figure 3b) are proposed as a convenient technique for improving soft soils that have un-drained shear strengths lower than 15 kPa. Encasing the stone column within Geo-textiles made up of woven high strength synthetic yarns increases the stiffness of the column and thereby increases its load capacity and no clogging of soft soil with granular stone column when compared with the ordinary stone columns.

(a) Ordinary stone column; (b) Geo-textile encased stone column

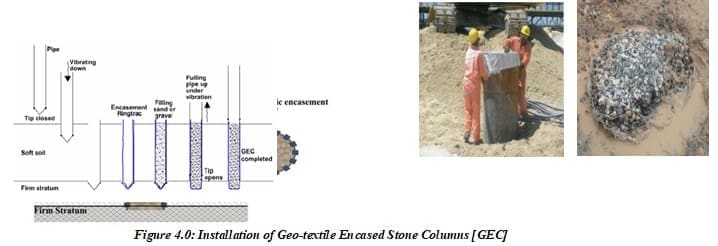

The installation of Geo-textile encased stone columns involves driving a steel casing with a closed end tip into the ground to create a hole. A Geo-textile tube is then inserted inside the steel casing and the granular material is then backfilled. The tip of the casing is opened as the steel casing is withdrawn from the soil with vibration to densify the infill material as shown in figure 4.0.

B. The Geo-textiles

Natural fibers such as flax, jute and ramie can be used for most temporary application where, for instance, soil erosion is the problem. The Geo-textiles made from these natural polymers help to prevent the erosion of soils by allowing vegetative growth and their subsequent root establishment. Once the purpose is served, the Geo-textile material gradually disintegrates into the soil. In most medium to long term applications as in Geo-textile Encased Columns, Geo-tubes/bags where physical and chemical durability and dimensional stabilities are of prime concern, synthetic fibers are preferred. There are currently at least four synthetic polymers considered suitable for this purpose; they include: polypropylene, polyester, polyethylene and polyvinyl chloride.

Woven Geo-textiles form the major component of all Geo-textile products. The manufacturing process involves weaving of high tensile strength [≥ 6 gpd] and low elongation yarns [<12-14%] into fabrics. Yarns of Polyester, Polypropylene, and nylon in multi-filaments /monofilament/tape forms are widely used in weaving. Multifilament fabrics are characterized by their high strength and resistance to stretch, these properties being enhanced as the tenacity of the yarn increases. Multifilament yarns are also more flexible than monofilaments, a property which facilitates weaving of the tightest and most efficient of all woven fabrics. Filament yarns of linear density 1100 dtex and 2200 dtex are predominantly used in plain weave constructions for Geo-textiles. Wide width looms are specifically used for producing Geo-textiles.

Woven Geo-textiles are mainly used for:

* Reinforcement of Unpaved Roadways, Paved Roadways, etc

* Separation applications in, Unpaved Roadways, Paved Roadways, Sediment Control, etc.

* As components in geo-composites

* Geo-textile Encased Columns [GEC] for Construction of roads

* Geo-tubes /Geo-bags for control of soil erosion in river banks/coastal areas

C. Disadvantage of Present Tubular Geo-textiles

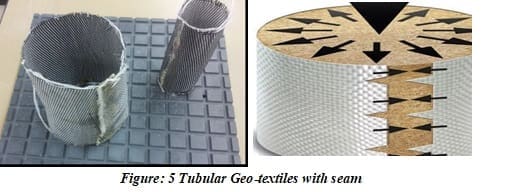

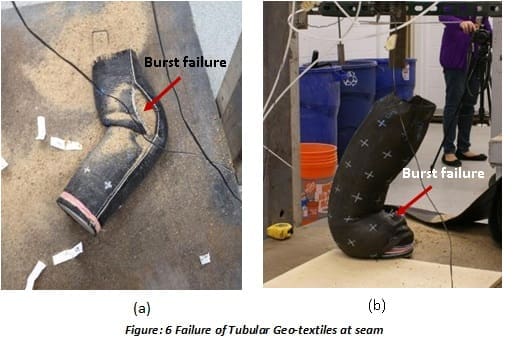

In majority of applications flat fabric suffices the requirement. However, in some special cases tubular structure of the Geo-textile is required for example in GEC, Geo-tubes, Geo-bags; which is formed by stitching fabric end to end [Figure-5]. Seam is always a problem in a stitched circular fabric as it introduces a weak point in the fabric compared to other parts. The functional properties also changes in the seam part of the fabric. During application all parts of the fabric come under same stress and always there are chances of failure at Seam. The Seam failure can be highly dangerous to the structure.

The Loading tests performed on Geo-textile encased sand columns in both air and surrounded with weak soil showed that the Geo-textile sleeve typically failed at a seam. This finding supports the practice of using seamless encasements in real structures [Figure 6].

D. Overcoming the shortcomings of present Tubular Geo-textiles

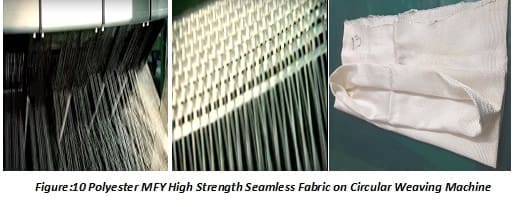

In tubular Geo-textile the fabric is stitched end to end to make a circular form, however the seam makes the fabric weak and ineffectual for the purpose. In an attempt to resolve the selvedge related issues in tubular Geo-textiles SASMIRA, Mumbai have developed ‘High Strength Cost effective Seamless Technical Circular Fabric from Heavy Denier Polyester Multifilament Yarns’ which will give significant advantage. It can be used for Geo-textile Encased Columns in construction of roads in soft soils [Figure 1] and also in Geo-bags& Geo-tubes for control of soil erosion in river banks/coastal areas where stitched fabric is used [Figure 7]. SASMIRA has filed patent for this development [Application No.E-2/2502/2017-MUM Dated 15/11/2017]. At present there is no manufacturer for this kind of Geo-textiles in India.

E. Development of High Strength Seamless Fabric with Polyester Multi-filament Yarns

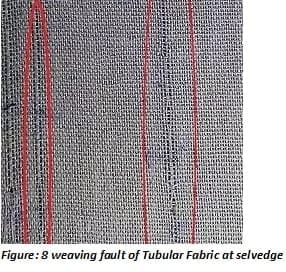

It is pertinent to mention that Tubular Geo-textile was attempted on conventional shuttle loom on double cloth principle. However, due to coarse and low twist synthetic Multifilament Yarns, there was thread distortion and filament rupture leading to reduction in desired properties in selvedge region due to use of strong temples as compared to body [Figure-8].

Therefore, to avoid the selvedge related problems in the fabric circular weaving principle was adopted. Circular Loom is a weaving machine in which two or more shuttles move simultaneously in a circle, laying weft threads in a section of warp thread, forming a shed. They are used in the production of hoses and bags. The warps rise and fall with each shuttle passage, unlike the common practice of lifting all of them at once [Figure.9]. Here the bobbins are mounted on the creel which serves as warp and weft is inserted by rotating shuttles in the multiple plain shed formed by the Heddle belts connected to cams. The circular fabric is then pulled by take up roller and finally wound on winder.

Advantages of Circular loom:

Circular Weaving Principal – Simple technology

Multiple pick insertion – High Productivity

No Selvedges – Not possible on modern shuttle-less looms

Economical as many steps of conventional weaving are not required like re-winding, warping, frequent gaiting etc.

The specifications of the fabric for use in Geo-textile Encased Columns [GEC] were decided like yarn Tenacity, count, EPI, PPI and TPM of warp and weft. After several trials the Proposed Seamless fabric was developed on the Circular Loom after modifications/precautions as under:

1. Controlled warp let-off

2. Smooth warp passage

3. Application of anti-static oil

4. Optimum twist application

5. No cuts/worn out tensioners and heddles

6. Suitable Take up roller cloth for heavy fabric

7. Correct rating of take up & batch roller motor to take the load

8. Compact wound weft bobbin

9. Clear Shed Formation

10. Ceramic guides at important points

11. Frequent cleaning of machines with compressed air

12. Strong spreader arrangement

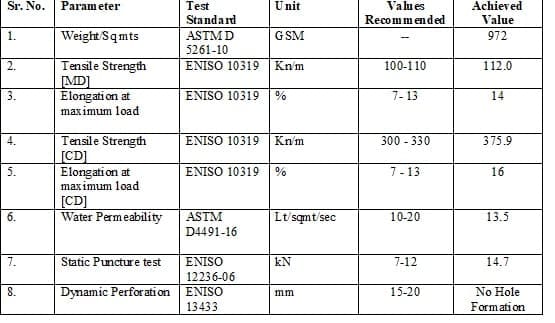

The test results of 400mm diameter Seamless Circular fabric developed with high tenacity Polyester Multi-filament Yarns [MFY] for Geo-textile Encased Columns [GEC] are as under:

From above it can be inferred that the developed sample meets the necessary specifications.

Benefits of developed Seamless Tubular Geo-textile for stone columns:

The seamless circular structure with Multi-Filament Yarns capable of being developed on existing circular weaving looms with locally fabricated modifications

Reinforcement sleeve diameters between 0.4 m and 1.0 m can be made

The developed fabric is technically in compliance with recommended parameters

The indigenous Circular looms are costing from Rs. 15- 45 lacs as per diameter. Whereas, imported shuttle weaving machines capable of making tubular structure on double cloth principle costing about Rs. 3-4 Crores. The conventional technology will further add to final cost due to higher conversion charges.

High Denier yarn can be woven easily [ up-to 20000 dn & more ]

High GSM fabric can be developed [ ≥ 1000 GSM ]

High Tensile strength fabric possible [≥400 kN/m]

Affordable Cost of circular fabric for Indian market

Suitable for soft soils with cu < 15 kN/m²

Almost all settlement takes place within construction period

Adjacent buildings are unaffected by settlement

System is fully loadable immediately after completion

High embankments can be built in short time with no danger of bearing failure

System is highly adaptable to local conditions and loads

No need to dispose of waste or contaminated spoil (where displacement method is used)

No adverse impact on groundwater flow

Underlying aquifers protected by base seal

Economical use of site space and lower excavation, disposal and imported material costs

Reduction in construction time and cost

F. Conclusion:

The tubular Geo-textile formed by stitching fabric end to end has a major disadvantage due to the seam being weak and thus cannot be used where heavy loads are acting constantly. The seamless fabric will be ideal for such applications. The Geo-textile Encased Column (GEC) made with seamless fabric will be ideal as a foundation solution for earthwork structures built on weak sub-soils. This pile-like load-carrying system is a quick, cost-effective method of providing a foundation for embankments on ground with low bearing capacity. The particularity of the seamless GEC system is that the outwardly directed radial horizontal stresses in the columns are counteracted not only by the inwardly acting pressure of the soft soil, but also by the radial resistance of the Geo-textile casing. The circumferential tensile forces generated in the casing provide radial support to the columns and safeguard the equilibrium of the system, thereby allowing its use even in very soft soils. This fabric also acts as filtration-stable mega-drains, which speed up the settlement and consolidation process. Potential later settlement is thus either prevented or can be offset by means of temporary cover fill, as required by the particular project. The circular weaving technology developed for making seamless circular technical fabric is simple and can be easily adopted. The cost of modifications is also very economical. Further, with locally availability of technically compliant High Strength Circular Seamless fabric at affordable rates; the development of infrastructure projects is ensured to boom.

Acknowledgement:

The authors wish to acknowledge the Ministry of Textiles, Government of India for financial support for the execution of this project. The authors also acknowledge M/s Kusumgar Corporates, Mumbai and Dr. M.K Talukdar for partial funding and technical support for this novel development.

References:

- Stability Analysis of Geo-textile Encased Sand Columns- Dr. Shaymaa Kadhim, University of Technology, Baghdad, 2016

- Handbook of Technical Textiles– A R Horrocks and S C Anand Published by Woodhead Publishing Limited in association with The Textile Institute , England

- Geo-synthetic Encasement for Stronger and Stiffer Stone Columns, Dr. K Rajagopal, Department of Civil Engineering, IIT Madras, Chennai