B. Swami, P. B. Malakane

Research Scholar, Assistant Professor, Department of Textiles, D.K.T.E`s Textile & Engineering Institute, Ichalkaranji

Abstract

The quality of spun yarn depends upon various factors like fibre properties, technological process variables, atmospheric condition etc. Among many, one important technological parameter is the orientation of fibre in yarn. Contribution of fibre properties towards yarn properties will be better if fibres are parallel towards yarn axis. Orientation of fibres in sliver and roving influences the fibre orientation in yarn. In different spinning stages machines and process variables on these machines affect the fibre orientation in sliver, roving and yarn. Carding and drawing processes are designed to increase the parallelism of fibres. Carding is the initial stage and important process for fibre individualization and straightening. In carding process the hooks are formed. This phenomenon deteriorates the yarn quality. So, a fibre configuration and hook fibre in card sliver determines the yarn quality in large extent. This paper reports a glimpse on the different measurement techniques of fibre orientation parameters and impact of carding process variables on fibre orientation and quality.

Keywords

Fibre orientation, Orientation index, Cutting ratio, Combing ratio, etc

- Introduction

Since last six decades, number of direct and indirect [2-4] methods have been investigated to describe the fibre orientation like fibre straightness, fibre extent, helix angle, coefficient of relative fibre parallelisation, proportion of curved fibre ends, migration parameters, etc. In direct method, tracer fibres are viewed through projection microscope. In indirect method like Lindsley and modified Lindsley the fibre orientation and parallelisation in sliver and roving are measured in terms of weight ratios. The behaviour of single fibres is taken in to account to measure orientation parameters in direct method and from it the sliver or roving or yarn characteristics are extrapolated, which is not realistic. This is because of the number of fibres in the cross section are more and overlapping of fibres is not considered.

In carding is the most important process. Card process parameters influence the fibre orientation and property of sliver, roving and yarn. Carding is the process stage where hooks are formed. The type of hooks and their amount decides the fibre orientation and properties of sliver, roving and yarn. Leading hooks are lesser and smaller than trailing hooks . Configuration of fibre are classified in five groups, namely

(i) leading hooks,

(ii) trailing hooks,

(iii) both ended hooks,

(iv) fibre ends are not hooked but not necessarily straight and

(v) knotted fibres

In card sliver 50% are leading hooks, 15% trailing hooks, 15% both ended hooks and less than 20% of fibres are not hooked at all. During fibre transfer from cylinder to doffer hooks are formed due to fibre buckling. Various researchers have investigated effect of carding process parameters on fibre orientation and quality of sliver, roving and yarn and the quality of carding operation.

- Measurement Of Fibre Orientation

2.1 Direct Method

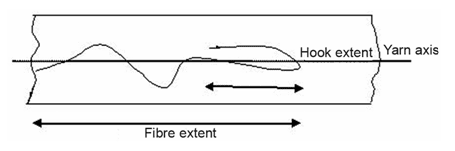

The first method for measurement of fibre orientation in sliver, roving and yarn was direct method. This method was based on the use of optical tracer fibre technique and ultraviolet rays for study of hooks. In optical tracer fibre technique [1, 5], 0.1 – 0.3% fibres are dyed with any dark colour. These tracer fibres are mixed with parent fibres in early stage of blow room for better mixing. In optical fibre technique the sliver or roving or yarn is immersed in a solution which is having the same refractive index as of parent fibres. In this the parent fibres optically dissolve while path of dark coloured tracer fibre can be easily seen in horizontal plane and vertical plane through microscope. The optical tracer fibre technique can be used to measure the fibre orientation parameters, like fibre extent, fibre arrangement, degree of parallelisation, type of hooks, and hook extent in sliver, roving and yarn. The schematic view of a fibre seen under microscope for the fibre extent study is shown in Fig. 1.

Fig. 1- Schematic view of hooked tracer fibre seen under microscope

As the parameters like fibre extent and hook extent are dependent on the length of fibres used. Hence the same parameters cannot be compared in different samples prepared from different fibre lengths.

Two newly parameters are proposed – fibre overlap index (FOI) and fibre pair overlap length (FPO). Longitudinal behaviour of fibre can be measured by FOI and FPO, which gives the total contact length between fibres.

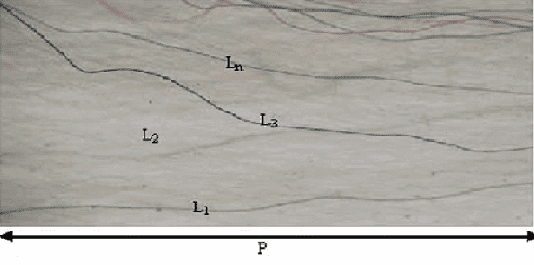

In the UV tracer fibre technique the fibres are dyed in any fluorescent dye, and this technique can be used to measure the fibre orientation in web from card or draw frame collecting on black boards. New index name fibre straightness index (FSI) which gives information about fibre straightness and comparable for different samples from different fibres. FSI is the ratio of total axial projected length of a fibre to the actual length of that fibre in a section of length observed directly with the microscope . Fibres used to for FSI study is shown in Fig. 2. The FSI can be calculated by below equation.

FSI= n x P / (L1 + L2 + L3 +…+ Ln)

Where n is the number of fibres; P and L1, L2, are the fibre extent and actual lengths of the fibre in the section observed.

Fig. 2- Section of sliver seen under microscope

Fig. 2- Section of sliver seen under microscope

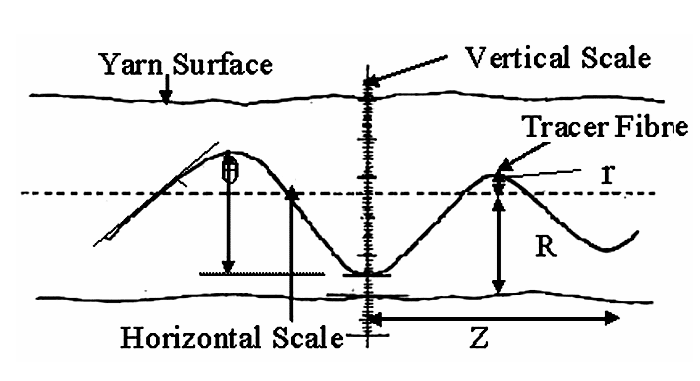

To study the fibre migration in the yarn, tracer fibre technique is also used. Mathematical formulae are used to calculate the migration parameters. These formulae specify overall tendency of a fibre to be near the centre or at the surface of the yarn, termed as mean fibre position (MFP); the rate of change of radial position, termed as mean migration intensity (MMI); and the magnitude of the deviations from the mean position or the amplitude of the migration, termed as root mean square deviation (RMSD). The schematic view of a fibre seen under microscope for fibre migration study in yarn is shown in Fig. 3.

Fig. 3 – Schematic view of a tracer fibre seen under projection microscope

To calculate the migration parameters following formula are given by Hearle et al . Where n observations of Y were made over a length Zn. Mean migration intensity

2.2 Indirect Method

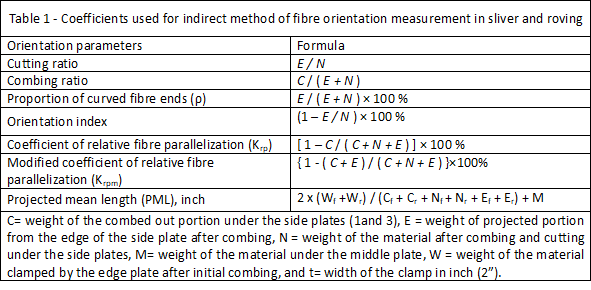

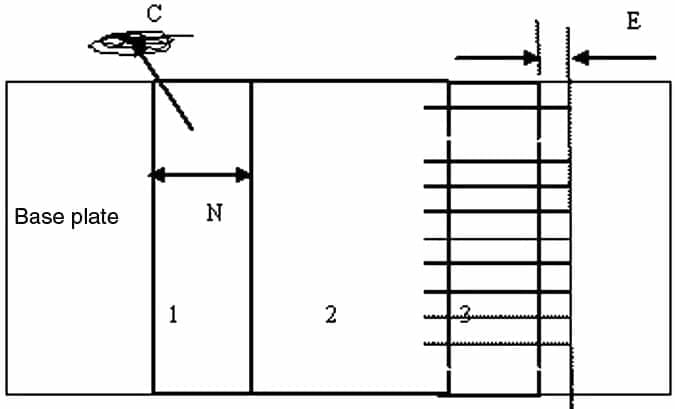

In the indirect fibre orientation measurement methods, like Lindsley [2] and modified Lindsley few coefficients are calculated for measuring fibre orientation in sliver and roving. Three indices- cutting ratio, combing ratio and orientation index were calculated to measure the fibre orientation in sliver and roving. Two new coefficients are derived by Leon`teva [3] known as proportion of curved fibre ends ‘p’ to represent curved fibre ends as well as their length and coefficient of relative fibre parallelisation ‘Krp’ to represents degree of fibre parallelisation and straightening in sliver or roving [6]. The schematic view of the instrument used for indirect fibre orientation measurement is shown in Fig. 4.

Fig. 4. Schematic view of the instrument used for indirect fibre orientation measurement

The various coefficients used for indirect method of fibre orientation measurement are given in Table 1.

Fibre orientation in sliver and roving are also measured by classical fibrogram analysis [4]. The excess span length from majority hook beards over span length from minority hook beards was more clearly shown for the 50% and 66.7% span lengths than for the 2.5% span length [10].

Various methods are used to measure the fibre orientation in sliver, roving and yarn. Selection of method depends on the purpose of study.

3. Effect Of Card Process Variables On Fibre Orientation

Card is the heart of spinning. Carding is responsible for fibre straightening and complete opening. In carding process majority of fibres change their configuration during transfer from cylinder to doffer. During fibre transfer hooks are formed due to fibre buckling. Trailing hooks are dominant [5]. In card sliver 50% are trailing hooks, 15% leading hooks, 15% both ended hooks and less than 20% of fibres are not hooked at all [7]. Various card process parameters, like sliver weight, doffer speed, carding force, carding settings, etc. influences the card performance, fibre orientation and quality of sliver, roving and yarn.

3.1 Influence Of Card Sliver Hank

Change in sliver hank on card influences the fibre orientation in sliver. Coarse sliver hank, increases relative coefficient of fibre parallelisation, projected mean length and decreases the proportion of curved fibre ends. Increase in operational layer due to increase in sliver hank results increase in carding force and inter fibre friction. This ultimately results in increases the fibre straightening and decreases the proportion of curved fibre ends [6, 11]. At low carding rate, with coarse sliver hank caused smaller increase in trailing hooks but definite decrease in leading hooks. Overall projected mean length decreases with the coarse sliver hank. Card web neps and yarn imperfections increase with the increase in carding rate. At lower carding rate, sliver weight has little effect on card web neps. However, at higher carding rate the coarse sliver appears to have fewer neps. The yarn imperfections increase as the sliver hank changed to coarser. Increase in carding draft for same sliver hank with heavy feed lap weight, increases imperfections in same yarn count. Increase in carding rate improves the fibre orientation and draw frame sliver uniformity. Sliver hank and carding rate had little effect on the yarn uniformity. With increase in carding rate, the strength and elongation decrease marginally [6, 11-14]. Both fibre parallelisation and fibre hooks decrease as card sliver weight increases.

3.2 Influence Of Doffer Speed

Higher card production rate increases the leading fibre hooks in the sliver, because of the reduced peripheral speed ratio of cylinder and doffer [15]. Bad carding, where cylinder speed is reduced and doffer speed is increased, gives better parallelisation even with less fibre separation. Improvement in fibre parallelisation in the subsequent processes is better with good carding, probably due to better fibre separation. Projected mean length (PML) which measures the fibre parallelisation was higher under bad carding condition at card, draw frame and riving stages. Because of better fibre separation and degree of parallelisation with good carding, the rate of improvement of parallelisation in the subsequent process was high [16]. Bad carding condition causes reduction in majority hooks and increase in minority hooks at the card stage. Majority hooks are more under good carding at the card stage and this trend continues up to first and second drawing stages. This indicates that the rate of unhooking during drafting at drawing remains same, irrespective of the carding condition [16]. Nep removal at carding significantly improves with the reduction in card production due to intensive carding action. High production rate increases neps in drawing because of inferior carding quality. Better carding quality with lesser production increases yarn tenacity [17]. Thick places and neps and U% in ring yarn increases with the increase in card production [18]. Decrease in card production rate improves the yarn properties.

3.3 Influence Of Carding Force

The force required to individualise a tuft in between cylinder-flat zone is called carding force. Carding force increases with increase in operational layer on the cylinder and tuft size. Carding force influences the quality of carded sliver with regard to neps and regularity. Increase in carding force per unit load decrease both the neps content and the U % of the sliver.

3.3 Influence Of Carding Process On Yarn Characteristics

Carding process influences the preparatory products and yarn quality. Intensive opening by changing carding process improves yarn regularity and tenacity up to certain extent. Intensive opening generates short fibres, leading uncontrolled drafting and make yarn uneven and weak. Increase in the openness at higher level increases yarn hairiness because of short fibre generation . Lesser fibre individualisation causes more slubs, thick places and neps in yarns.

Process of carding changes the fibre arrangement in sliver, roving and yarn. Quality of carding depends on feed material weight, carding force, production rate and processing parameters. Process of carding generates hooks. Majority of hooks are trailing hooks followed by leading and both ended hooks.

4. Conclusion The fibre orientation parameters of sliver, roving and yarn are measured with different measuring techniques. Concept of measuring the fibre orientation was almost same in all the measurement techniques. Modifications in various measuring techniques were done. Fibre orientation parameters correlate with sliver, roving and yarn characteristics; and used for selecting the process parameters in spinning preparatory.

Carding process affects the fibre orientation in sliver, roving and yarn. Performance of subsequent process and yarn characteristics are affected by the carding quality.

References

- Morton W E & Summers R J, J Text Inst, 40, 106, (1949).

- Lindsley C H, Text Res J, 21 39-46, (1951).

- Leont’eva I S, Tech Text Ind USSR, 2, 57-63, (1964).

- Iyer I K P, Parathasarthy M S & Sundram V, Resume of Papers, Twenty First Joint Technological Conference of ATIRA, BTRA, and SITRA, 12-15 (1980).

- Morton W E & Yen K C, J Text Inst, 43, T463-T472, (1952).

- Akshay Kumar, S. M. Ishtiaque & K R Salhotra, Indian J Fibre Text Res, 33, 451- 467, (2008).

- Klein W, A short staple spinning series, A Practical Guide to Opening and Carding (The Textile Institute), 1987.

- Sengupta A K & Chatopadhyay R, Text Res J, 52, 178-181 (1982).

- Hearle J W S & Gupta B S, Text Res J, 35, 788 (1965).

- Audivert R, Text Res J, 41, 365-366 (1971).

- Ishtiaque S M & Vijay A, Indian J Fibre Text Res, 19, 239-246 (1994).

- Simpson J & Fiori L A, Text Res J, 44, 327-331 (1974).

- Basu A, Asian Text J, (4), 74-78, (2002).

- Simpson J, Text Res J, 42, 590-591, (1972).

- Wolfgang T, Melliand Textilber, 65, E211- E215, (1984).

- Nerurkar S K, Indian J Text Res, 4, 63-70, (1979).

- Rakshit A K & Balasubramanian N., Indian J Text Res, 101, 58-162, (1985).

- Rakshit A K & Balasubramanian N, Indian J Text Res, 8, 95-100, (1983).

- Sengupta A K, Vijayaraghavan N & Singh A, Indian J Text Res, 8, 59, (1983).

- Sengupta A K, Vijayaraghavan N & Singh A, Indian J Text Res, 8, 64, (1983).

- Sengupta A K, Vijayaraghavan N & Singh A, Indian J Text Res, 8, 68,(1983).

- Ishtiaque S M, Chaudhuri S & Das A, Indian J Text Res, 28, 405-410, (2003).