ANTI BACTRIA, 3 X DRY AND C CHANGE TYPE

RAVISHANKAR – KS TECHNICAL AND MANAGEMENT CONSULTANTS, VADODARA

[email protected]……………..March 2017

Introduction :

In the recent years everyone would have read much about smart textiles which incorporate electronics into textiles for various sensing and reporting functions. While this is going to the trend and we shall see that a part of conventional textiles ( which has not changed in basic function and appearance over last hundreds of years), there is a considerable development taking place in functional or performance textiles. An attempt is made here to touch upon various functional textiles for the reader’s information and focus. Only three types of functional finishes will be considered in this article out of over Ten types of commercially viable finishes. The remaining will be covered in the next few articles later

Materials

The performance in textiles is achieved by two basic methods

- Choice of right raw material for basic fabric

- Choice of right finish or laminations

The choice of performance raw material is limited and suppliers are big multinational with their own proprietary properties and certification procedures. There is little scope for a manufacturer to use his creativity and maintain market leadership by their own uniqueness or process know how.

On the other hand the functional finishes allow the processor to use a combination of chemicals and process techniques and special knowhow to achieve the new performance properties. This type of finsh also suits development of special products to meet exacting requirements in Army, Electronics, Safety and Aviation markets.

A typical textile manufacturer will be looking to add value to existing conventional textile raw materials like Polyester, Cotton, viscose, polypropylene, acrylic etc., which can processed easily on his existing machines or with marginal capital investment.

Many of the readily available finishes are proprietary in nature and process know how a closely guarded secret. Many companies like Schoeller, Outlast, Coolmax etc., license the technology and certify the product. In Europe and USA many of the products described are already in use for the last six to seven years and many well known brands are making garments using these licensed products. It must be made clear the cost of production has very little correlation with the Selling price for these products. It is the Brand image, Product performance assurance and need of buyer in such products that determine the final selling price of these products. During the discussions with various industry personnel it was evident that maximum gain in the value chain as today is with the Garment manufacturer who label these products as 3X-dry, Outlast etc., There are many more brands in the market, I have only mentioning a few.

The new technologies of fabric finish considered are expected to replace the older technologies like Fluorocarbon, silicone finish, simple porous membranes, etc., The advent of Nanotechnology has made the finishes more predictable and permanent in performance. However, the new technology is patented and available with a few companies worldwide making it imperative to license the technology. It is to procesors advantage, in the recent days there are many companies offering competing Nano- technology products without the licensing and franchisee models. However one has to make their own R & D efforts to arrive at special processes for these chemicals.

SOME TYPICAL FINISHES OF SIGNIFICANCE

- 3X-DRY

Previously the moisture was transported from inside to outside of a garment using two different types of materials. For example use of Nylon in the inside layer and Polyester on the outer layer of laminated fabric. This was more expensive and had limited use due the increase in weight of fabric, stiffness generated during lamination and overall higher cost.

Schoeller developed the new technique using special chemical finish on either side of the fabric. This type of finish is expected to be more user friendly and economical. Schoeller Technologies has developed the technology and process know how.

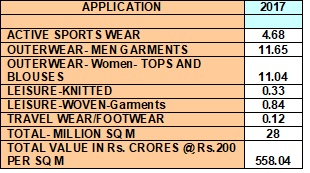

A typical estimate for 3X-dry type of products in India is given below for your appreciation of typical base market for such finishes in India alone.

(Million sq m of fabric demand estimate for India)

Ref: Market study of KS Technical

As more companies other than Scholller have developed similar chemicals giving the freedom to the end users to experiment and obtain equivalent or better properties developing his own proprietary processes.

Discussions with various persons in the Garment industry and Textile finishing, we have gathered that market exists for such special products, particularly due to tropical climate conditions in India.

2. C-CHANGE

C_change™ is a water and windproof membrane technology which is capable of independent flexible adaptation of its moisture vapour permeability. “This flexible adaptability based on a clever use of material properties has made it possible to improve the comfort of wear of membrane clothing in changing climates“

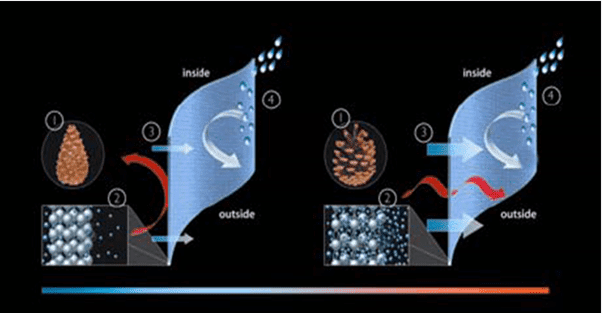

C-Change bionic climate membrane reacts in a way similar to that of a pine cone which opens and closes in response to different weather conditions. As soon as the ambient temperature rises, or greater moisture is produced as a result of body heat, the polymer structure of the membrane opens and allows excess moisture to escape to the outside air. As soon as the body produces less heat energy and therefore less moisture, the membrane structure contracts again. Here body heat is stored and protection from chilling and shivering built up. In addition, C_CHANGE™ offers moisture vapor permeability at the highest level. C_CHANGE™, the new membrane technology from schoeller® reacts to changing temperatures and activities. In addition, it offers moisture vapor permeability at the highest level and is wind- and waterproof.

This means that C_CHANGE™ always ensures an optimum body climate.

Open in response to heat or increased activity:

At high temperatures, or during sporting activity, the structure of the c_change™ membrane opens as body moisture levels rise. Excess heat can escape to the outside air.

Closed in response to cold or reduced activity:

Due to the lower level of body moisture development in cold weather or during periods of inactivity, the structure of the membrane closes, retaining the heat directly at the body. Shivering or chilling is effectively prevented

“C” CHANGE material is the product of Schoeller Technologies and is patented. However similar materials are available from Fintetex, Tetratex, Goretex and other European companies.

The function of C change is shown in diagram below.

The market in India for C change materials is unexplored so far. It is however likely to find use as winter wear in many parts of the country where in the temperatures are not too low. Children protective wear particularly for the school going kids is a likely market that will grow.

Special lamination machines are required for the C change membrane to be incorporated with the functional fabrics. The cost of the machine depend on width and speed.

One of the market survey report show that the potential for this type of product in India is over 500 Lakh meters.

3. ANTI-BACTERIA FINISHES

Bacterial growth in textiles can cause many a discomfort to the wearer mainly in

SKIN IRRITATION

CHANGE OF COLOUR

BAD ODOUR

Over the years many a chemical treatments have been developed including Silver ion treatment to achieve the long term anti bacteria result. However success still eludes a cost effective and long term solution as many a chemical finishes are not resistant to multiple washes of a garment . Silver based systems have their own problems in skin cancer and also pollution control in process houses. Anti Bacteria finishes become more important in Bed Linens, Towels and Medical drapes and Gowns.

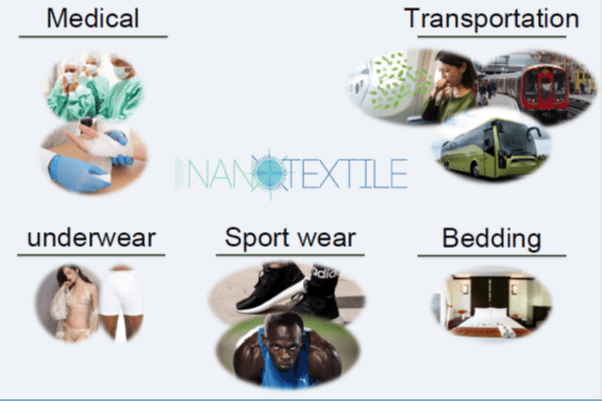

Applications of Anti-bacterial treatment is shown the picture below.

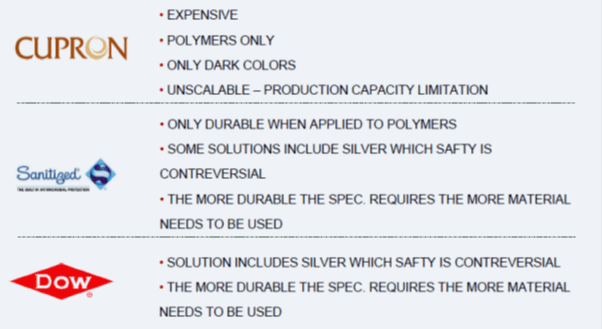

The typical known solution for Anti Bacterial treatment along with their characteristics is illustrated in the following picture.

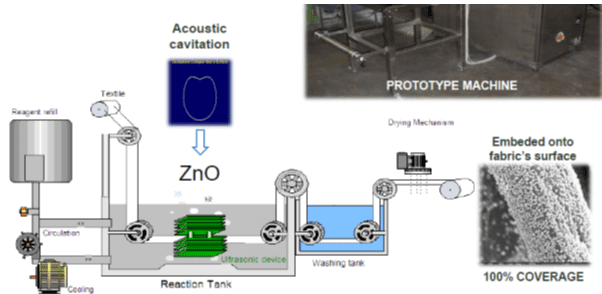

We understand a New Nano-technology system is being worked out In Israel which gives much longer life for this finish at the same time making the process more cost effective compared to Silver based chemicals. The process technology ensure that the chemicals enter the interstices of the yarn and fabric enabling durability over 75 washes in most cases. It is also claimed that the process can be applied to fabrics of cotton, polyester, blends of cotton and polyester fibers, Nylon and other conventional fibers. The company claims that It can be applied to both spun yarn fabrics and filament based fabrics with equal efficacy.

The typical process is given below for illustration

The market in India and tropical countries for Anti-bacteria finish is estimated to be very high. Survey reports are available in the market from Market research companies. In addition to good demand in Garment and intimate wear sector, the potential is high in the Medical and Hospitality segments also.

Conclusion

There is a huge potential fabric with new finishes in India and am sure the readers from the processing and garment sector will like to take advantage of these technologies which are available to make more value added products.

From

KS Technical and Management Consultants

B-2, Sandalwood , 22, Pratapgunj Soc

Vadodara 390002, India

+919825244940