Tanvi Munjal

In the heart of Italy’s fashion capital, Milan, a groundbreaking innovation emerged in 2011 that would challenge conventional textile production methods. Two students, Adriana Santanocito and Enrica Arena, developed a revolutionary concept: transforming citrus waste into a sustainable textile fibre. This innovation, now known as Orange Fiber, represents a significant leap forward in sustainable fashion and circular economy practices.

The Need for Orange Fibre

The textile industry faces numerous environmental challenges, from excessive water consumption to chemical pollution. Simultaneously, the citrus industry generates millions of tons of waste annually, with Italy alone producing about 700,000 tons of citrus waste yearly. Orange Fiber presents an elegant solution to both problems by:

- Converting citrus waste into valuable materials

- Reducing landfill burden

- Creating sustainable alternatives to traditional textiles

- Supporting circular economy principles

The Production Process: From Waste to Wearable Fabric

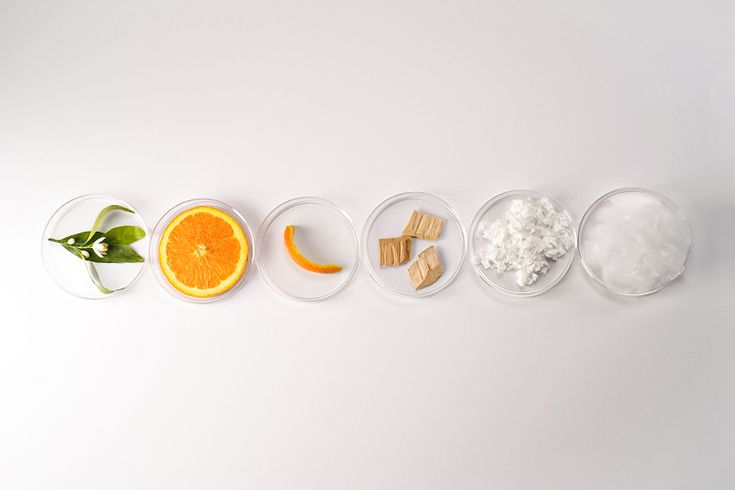

Orange Fiber’s patented process extracts cellulose from citrus waste to create sustainable fabrics. The production process involves several steps:

- Collection of Citrus Waste: The process starts with gathering pastazzo, the wet citrus residue from juice-processing plants. This byproduct is rich in cellulose, which is essential for fibre production.

- Cellulose Extraction: The pastazzo undergoes a patented process to extract the cellulose.

- Fibre Production: The extracted cellulose is then processed into a fibre. This step is often done in partnership with other companies. For instance, Orange Fiber collaborates with the Lenzing Group in Austria, where the cellulose is spun into a lyocell fibre containing both orange and wood cellulose using a spinning process for ionic liquids.

- Yarn Production: The fibre is then transformed into yarn. Orange Fiber partners with companies like Pozzi Electa in Italy for this step, utilising processes like carding, coupling, twisting, and winding to create high-quality yarn.

- Fabric Creation: The yarn is woven into fabric. This can be done purely with the orange fibre or by blending it with other materials like silk, cotton, or elastic textures to achieve different characteristics.

- Finishing (Optional): In some instances, nanotechnology is used to embed essential oils from citrus fruit peels and vitamin C into the fabric.

This process transforms waste into a valuable resource, offering a sustainable option to traditional textile production.

Characteristics and Properties

- Silky Texture: Orange Fiber has a soft and silky texture, similar to high-quality silk, making it suitable for luxury fashion.

- Biodegradability: The fibre is biodegradable, which means it can decompose naturally, reducing environmental impact.

- Versatility: Orange Fiber can be used to create a variety of fabrics, including lace silk, satin, and viscose-like materials. It can be blended with other fibres to improve strength, durability, and elasticity.

- UV Protection: Orange fibre can provide UV (ultraviolet) protection.

- Good Drape and Anti-Wrinkle: The fabric drapes well, is anti-wrinkle, and can be wonderfully soft and strong.

- Potential Skin Benefits: Through nanotechnology, essential oils and vitamin C from citrus peels can be embedded in the fabric, potentially nourishing the skin.

Benefits of Orange Fiber

|

Environmental Benefits |

Economic Benefits |

Product Benefits |

|

Reduces agricultural waste |

Creates value from waste materials | Silk-like texture and feel |

|

Minimises water consumption compared |

Provides additional revenue |

Natural antibacterial properties |

|

Lower carbon footprint |

Reduces waste disposal costs |

Vitamin C-enriched fabric |

| Biodegradable end product | Opens new market opportunities |

Lightweight and versatile |

SWOT Analysis of Orange Fiber

A SWOT analysis provides insights into Orange Fiber’s position in the textile industry:

| Strengths | Innovative use of waste material, sustainable production process, unique properties like skin nourishment, and alignment with the circular economy. |

| Weaknesses | Seasonal production dependent on the availability of citrus waste, limited production capacity, and reliance on partner companies for spinning. |

| Opportunities | Growing demand for sustainable textiles, expansion into new markets, collaborations with fashion brands, and development of new applications and products. |

| Threats | Competition from other sustainable materials, potential fluctuations in the supply of citrus waste, challenges in scaling up production, and the need to meet stringent environmental regulations. |

Market Adoption and Industry Recognition

Several prominent fashion brands have embraced Orange Fiber:

- Salvatore Ferragamo (2017)

- First major fashion house to use Orange Fiber

- Created an exclusive collection highlighting the material

- H&M (2019)

- Included Orange Fiber in their Conscious Collection

- Brought sustainable innovation to the mass market

- E. Marinella (2020)

- Incorporated Orange Fiber into luxury tie production

- Demonstrated versatility in high-end applications

Conclusion

Orange fibre represents a significant advancement in sustainable textile fibre technology. Its unique properties, combined with environmental benefits, position it as a promising material for the future of textile production. Continued research and development in processing techniques and applications will further enhance its potential in the textile industry.