-Dr. N. N. Mahapatra

The high cost of growing and maintaining natural grass was one of the main driving forces behind the formation of artificial turf, which is a material made with synthetic fibres and resembles natural grass. Today, artificial turf or synthetic turf is gaining in popularity and is not only found in some of the world’s most important sports arenas, but also in residential lawns and commercial buildings. David Chany – who moved to Raleigh, North Carolina, in 1960 and later served as Dean of the North Carolina State University College of Textiles – headed the team of Research Triangle Park researchers who created the first notable artificial turf. That accomplishment led Sports Illustrated to declare Chaney as the man “responsible for indoor major league baseball and millions of welcome mats.”

Artificial turf was first installed in 1964 on a prep school recreation area in Rhode Island. The material came to public prominence in 1966, when AstroTurf was installed in the Astrodome in Houston, Texas. The state-of-the-art indoor stadium had attempted to use natural grass during its initial season in 1965, but this failed miserably and the field conditions were grossly inadequate during the second half of the season, with the dead grass painted green. Due to a limited supply of the new artificial grass, only the infield was installed before the Houston Astros‘ home opener in April 1966, the outfield was installed in early summer during an extended Astros road trip and first used after the All-Star Break in July.

The use of AstroTurf and similar surfaces became widespread in the U.S. and Canada in the early 1970s, installed in both indoor and outdoor stadiums used for baseball and football. More than 11,000 artificial turf playing fields have been installed nationally. More than 1,200 were installed in the U.S. in 2013 alone, according to the industry group the Synthetic Turf Council.

Maintaining a grass playing surface indoors, while technically possible, is prohibitively expensive. Teams who chose to play on artificial surfaces outdoors did so because of the reduced maintenance cost, especially in colder climates with urban multi-purpose “cookie cutter” stadiums such as Cincinnati’s Riverfront Stadium, Pittsburgh’s Three Rivers Stadium and Philadelphia’s Veterans Stadium.

With the number of indoor,domed or partially covered sports arenas increasing, the need for artificial turf has increased exponentially in recent years, as natural grass would require sunlight to grow.

The first-generation of artificial turf, known as Astro turf, was primarily short-pile fibres without infill. The second-generation turf system used sand infills. Today, however, third-generation turf systems are the most popular, and these use infills that are mixtures of sand and recycled rubber.

Astro Turf is an American brand name. It was invented by Donald Elbert, James Faria, and Robert Wright for sports use. It was given its name when in 1966 when it was installed in the Houston Astrodome stadium. … Since Astro Turf was invented,artificial grass products have changed beyond recognition.

ARTIFICIAL TURF;

In the early 1950s, the tufting process was invented. A large number of needles insert filaments of fiber into a fabric backing. Then a flexible adhesive like polyurethane or polyvinyl chloride is used to bind the fibers to the backing. This is the procedure used for the majority of residential and commercial carpets. A tufting machine can produce a length of carpet that is 15 ft (4.6 m) wide and more than 3 ft (1 m) long in one minute.

In the early 1960s, the Ford Foundation, as part of its mission to advance human achievement, asked science and industry to develop synthetic playing surfaces for urban spaces. They hoped to give urban children year-round play areas with better play quality and more uses than the traditional concrete, asphalt, and compacted soil of small urban playgrounds. In 1964, the first installation of the new playing surface called Chemgrass was installed at Moses Brown School in Providence, Rhode Island.

In 1966, artificial turf was first used in professional major-league sports and gained its most famous brand name when the Astrodome was opened in Houston, Texas. By the first game of the 1966 season, artificial turf was installed, and the brand name Chemgrass was changed to AstroTurf. (Although the name AstroTurf is used as a common name for all types of artificial turf, the name is more accurately used only for the products of the AstroTurf Manufacturing Company.)

Artificial turf also found its way into the applications for which it was originally conceived, and artificial turf was installed at many inner-city playgrounds. Some schools and recreation centers took advantage of artificial turfs properties to convert building roofs into “grassy” play areas.

After the success of the Astrodome installation, the artificial turf market expanded with other manufacturers entering the field, most notably the 3M (Minnesota Mining and Manufacturing) Company with its version known as Tartan Turf. The widespread acceptance of artificial turf also led to the boom in closed and domed stadium construction around the world.

In the early 1970s, artificial turf came under scrutiny due to safety and quality concerns. Some installations, often those done by the number of companies that sprang up to cash in on the trend, began to deteriorate. The turf would wear too quickly, seams would come apart, and the top layer would soon degrade from exposure to sunlight. Athletes and team doctors began to complain about the artificial surfaces, and blamed the turf for friction burns and blisters. Natural turf yields to the force of a blow, but an arm or leg driven along the unyielding surface of artificial turf is more likely to be injured. Since artificial turf does not have the same cooling effects as natural turf, surface temperatures can be 30° warmer above the artificial surfaces. Baseball players claimed that a ball would bounce harder and in less predictable ways, and some soccer players claimed that the artificial surface makes the ball roll faster, directly affecting the game. However, the National Football League and the Stanford Research Institute declared in 1974 that artificial turf was not a health hazard to professional football players, and its use continued to spread.

In the 1990s, biological turf began to make a comeback when a marketing of nostalgia in professional sport resulted in the re-emergence of outdoor stadiums. Many universities—responding to the nostalgia, advances in grass biology, and the fears about increased risk of injury on artificial turf—began to reinstall natural turf systems. However, natural turf systems continue to require sunlight and maintenance (mowing, watering, fertilizing, aerating), and the surface may deteriorate in heavy rain. Artificial turf offers a surface that is nearly maintenance-free, does not require sunlight, and has a drainage system. Recent developments in the artificial turf industry are new systems that have simulated blades of grass supported by an infill material so the “grass” does not compact. The resulting product is closer to the look and feel of grass than the older, rug-like systems. Because of these factors, artificial turf will probably continue to be a turf surface option for communities, schools, and professional sports teams.

It is a surface of synthetic fibers made to look like natural grass. It is most often used in arenas for sports that were originally or are normally played on grass. However, it is now being used on residential lawns and commercial applications as well. The main reason is maintenance—artificial turf stands up to heavy use, such as in sports, and requires no irrigation or trimming. Domed, covered, and partially covered stadiums may require artificial turf because of the difficulty of getting grass enough sunlight to stay healthy. Artificial turf does have its downside, however: limited life, periodic cleaning requirements, petroleum use, toxic chemicals from infill, and heightened health and safety concerns.

Artificial turf first gained substantial attention in the 1960s, when it was used in the newly constructed Astrodome. The specific product used was developed by Monsanto and called AstroTurf; this term since then became a generic trademark for any artificial turf throughout the late 20th century. AstroTurf remains a registered trademark, but is no longer owned by Monsanto. The first generation turf systems (i.e., short-pile fibers without infill) of the 1960s have been largely replaced by the second generation and third generation turf systems. Second generation synthetic turf systems feature longer fibers and sand infills, and third generation systems, which are most widely used today, offer infills that are mixtures of sand and granules of recycled rubber.

The quality of the raw materials is crucial to the performance of turf systems. Almost anything used as a carpet backing has been used for the backing material, from jute to plastic to polyester. High quality artificial turf uses polyester tire cord for the backing.

The fibers that make up the blades of “grass” are made of nylon or polypropylene and can be manufactured in different ways. The nylon blades can be produced in thin sheets that are cut into strips or extruded through molds to produce fibers with a round or oval cross-section. The extruded product results in blades that feel and act more like biological grass.

Cushioning systems are made from rubber compounds or from polyester foam. Rubber tires are sometimes used in the composition of the rubber base, and some of the materials used in backing can come from plastic or rubber recycling programs. The thread used to sew the pads together and also the top fabric panels has to meet the same criteria of strength, color retention, and durability as the rest of the system. Care and experience must also be applied to the selection of the adhesives used to bond all the components together.

The Manufacturing Process

Artificial turf is made from nylon or polypropylene fibres that are dyed green to take on the appearance of grass, and a backing that is probably made from polyester tyre cord covered in a layer of latex. It is made in a similar way to carpet: a yarn is made that is then inserted into the backing with a needle in a process called ‘tufting’ and then fixed with the latex. Astro-turf is so-called because it came to prominence in 1966 when it was used in the Astrodome, the indoor stadium of baseball team, the Houston Astros. It was installed to replace the real turf that had been starved of sunlight when the acrylic roof panels were painted white to cut down glare that affected players. Artificial turf has the benefit of being much easier and cheaper to maintain than real grass, but has its own drawbacks, one of which is the friction burns caused through sliding on astroturf. The use of polyethylene yarns in the most recent turfs has is an attempt to eliminate this problem.

The fibers are made from the highest quality resin pellets, which are melted down to create artificial turf fibers. It is during this process in which we add our UV inhibitors and other additives that help ensure our turf products will last. Since these features are built-in to the turf, they do not fade or wash away over time. This process of melting the resins to create the yarn is called extrusion.

It does seem like there are a lot of complicated steps in the manufacturing process, which is why you should be very picky about the artificial grass you choose for your project. As you can see, there are two main components to manufacturing synthetic turf: extrusion and tufting/coating. Many companies will purchase their yarn from overseas and tuft it in their own facility or extrude the yarn themselves and hire a third party to do the tufting. In both of these situations, the turf “manufacturer” sacrifices control over the process, which also means they sacrifice quality assurance. If quality and American made products are of importance to you, be sure you do your homework and know exactly what you are getting. At ProGreen, we have complete control from start to finish, and we can proudly stand behind our products as we know every single thing that went into making them.

The “grass” part of a turf system is made with the same tufting techniques used in the manufacture of carpets.

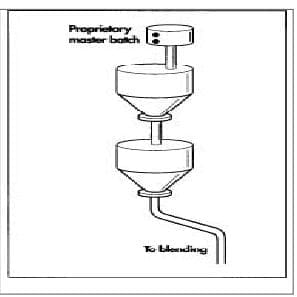

- The first step is to blend the proprietary ingredients together in a hopper. Dyes and chemicals are added to give the turf its traditional green color and to protect it from the ultraviolet rays from the sun.

- After the batch has been thoroughly blended, it is fed into a large steel mixer. The batch is automatically mixed until it has a thick, taffy-like consistency.

- The thickened liquid is then fed into an extruder, and exits in a long, thin strand of material.

- The strands are placed on a carding machine and spun into a loose rope. The loose ropes are pulled, straightened, and woven into yarn. The nylon yarn is then wound onto large spools.

- The yarn is then heated to set the twisted shaped.

- Next, the yarn is taken to a tufting machine. The yarn is put on a bar with skewers (a reel) behind the tufting machine. It is then fed through a tube leading to the tufting needle. The needle pierces the primary backing of the turf and pushes the yarn into the loop. A looper, or flat hook, seizes and release the loop of nylon while the needle pulls back up; the backing is shifted forward and the needle once more pierces the

How the ingredients of artificial turf are blended.

Backing further on. This process is carried out by several hundred needles, and several hundred rows of stitches are carried out per minute. The nylon yarn is now a carpet of artificial turf.

- The artificial turf carpet is now rolled under a dispenser that spreads a coating of latex onto the underside of the turf. At the same time, a strong secondary backing is also coated with latex. Both of these are then rolled onto a marriage roller, which forms them into a sandwich and seals them together.

- The artificial turf is then placed under heat lamps to cure the latex.

- The turf is fed through a machine that clips off any tufts that rise above its uniform surface.

- Then the turf is rolled into large v/lengths and packaged. The rolls are then shipped to the wholesaler.

Installation

Artificial turf installation and maintenance is as important as its construction.

- The base of the installation, which is either concrete or compacted soil, must be leveled by a bulldozer and then smoothed by

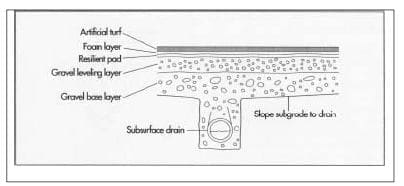

- A profile of artificial turf.

- A steam roller. Uneven surfaces will still be evident once the turf is supplied.

- For outdoor applications, intricate drainage systems must be installed, since the underlying surface can absorb little, if any, rainwater.Turf systems can be either filled or unfilled. A filled system is designed so that once it is installed, a material such as crumbled cork, rubber pellets, or sand (or a mixture) is spread over the turf and raked down in between the fibers. The material helps support the blades of fiber, and also provides a surface with some give, that feels more like the soil under a natural grass surface. Filled systems have some limitations, however. Filling material like cork may break down or the filling material can become contaminated with dirt and become compacted. In either case the blades are no longer supported. Maintenance may require removing and replacing all of the fill.

Quality Control

Because of the high use of artificial turf and the constant scrutiny by professional athletes, new products must undergo a number of tests as they are being developed. In 1994, the American Society for Testing and Materials (ASTM) published a list of standard methods for the testing of synthetic turf systems. It contains over two dozen tests for the properties of turf systems.

As part of ASTM’s testing, the backing fabric is tested for strength. The force it takes to separate the individual tufts or blades is also measured. In tufted turf, this test usually measures the strength of the adhesive involved. To test how resistant the turf is to abrasion, the ASTM recommends testing the fabric by running it under an abrasive head made of spring steel, while another ASTM test measures how abrasive the turf will be to the players. The ASTM also has tests that measure the shock absorbency of the turf system, and there are also tests to see how well the turf stands up during the course of a game or even prolonged tournament play.

Several quality checks are performed during the manufacturing process, as well. For example, according to AstroTurf Incorporated, the following quality checks are performed:19 checks for the raw materials, eight checks for extrusion, six checks for unfinished fabric, and 14 checks for finished fabric.

Byproducts/Waste

Defected artificial turf batches are discarded as are nylon yarn that is damaged. Completed turf is generally recycled, but not reused as artificial turf. The earth that is cleared from the installation site is transported to a landfill and discarded. Older turf that has been worn down is typically recycled.

The arguments about the environmental impact of artificial versus biological turf continue. Both create large amount of water run-off, adding to sewage problems. Chemical processes are used in the manufacture of raw materials for artificial turf, but most biological grass in stadium applications requires chemicals in the form of fertilizer and pesticides for maintenance.

The Future

The engineering and design of both artificial and biological turf systems are constantly improving. As new stadiums are built, the owners and architects strive to give a more old-fashioned feel to the structures, which usually means no dome or a dome that allows the use of biological turf.

Recent installations of artificial turf have included new advancements that serve both economic and environmental needs. Large holding tanks are built beneath outdoor installations. The water that runs off the surface is held in the tanks, and used later for watering practice fields or nearby lawns.

Another recent development has been a hybrid of filled turf and biological grass. Once artificial turf is installed, it is filled not with rubber or sand, but with soil. Grass seed is then planted in the soil, nurtured and grown to a height above that of the artificial turf. The resulting combination combines the feel, look, and comfort of biological turf with the resilience and resistance to tearing and divots of artificial turf. Of course, it also requires all the maintenance of both systems, and it is not suitable for most indoor applications.