Cotton still plays an important role in the textile industry worldwide. It is the dominant natural fibre of the 21st century. [GVW19] The quality of the textiles produced from cotton is significantly influenced by two factors: the type of cotton and its processing. The quality assurance begins with proper harvesting, followed by the ginning, which separates the fibres from the seeds of the plant. Concerning that ginning is at the very beginning of the textile process chain, the influence on the end product is particularly significant at this point. Therefore, cotton ginning plays a crucial role in achieving high-quality textile products. The question that arises at this point is how much the production of textile products depends on the quality of the raw material. Results show that the quality is greatly impacted by the production, correct settings and good machines can generate clean, long fibres. Based on this, measures will be presented to improve the conditions in the spinning mills to ultimately obtain better quality cotton. In order to achieve sustainable production, further long-term measures are then presented, like machine improvements and moisture control across the whole process.

Introduction

In the natural fibre ranking, cotton occupies the first place with a production volume of 26 million tons per year. It is followed by bast fibres with 3.2 million tons per year and animal wool with 1.1 million tons per year. [GH07, Sta19] Even synthetic fibres are still separated in wool and cotton types. Therefore, it is relevant to research opportunities to improve the quality of cotton and its production. Therefore, a study was conducted by Institut für Textiltechnik Augsburg gGm- bH which was supported by Deutsche Gesellschaft für internationale Zusammenarbeit GmbH (GIZ), funded by the Federal Ministry of Economic Cooperation and Development (BMZ) of Germany and assisted by the

Institut für Textiltechnik Aachen (ITA) of RWTH Aachen University, A.U.G.E. Institut of Hochschule Niederrhein (HSNR), Mönchengladbach, all in Germany and Raina Consulting Pvt. Ltd., Mumbai, India. It was carried out in India in the period from December 2020 to March 2022. For this purpose, inspections and interviews were conducted in Gujarat and Maharashtra over several months and visits of 2 weeks in November and December 2021.

In the following, various quality characteristics are briefly discussed. Afterwards the ginning preparation and the ginning machines necessary are mentioned and finally, proposals for measures are being presented.

State of the art

Cotton quality

Various factors have an impact on the quality of cotton. The quality can be determined on the basis of different characteristics, including [Cot18]:

- Fibre length

- Fibre fineness

- Short fibre content

- Yellowness

- Reflectance

- Seed count

- Moisture content

- Trash content

Ginning preparation

The ginning plant consists of several different machines. They undertake different tasks like supplying, cleaning, drying, feeding, and pressing the cotton. First the cotton is delivered to the ginning plant. There it is often stored for some time till the ginning takes place. Therefore, the cotton is fed into the facility by the feed- er. This process is usually done automatically by automatic feeders. Additionally, the separator does the first cleaning step by separating big trash contents like sticks, stones and branches out of the cotton. [MA94] Many of those mills do not invest into cleaning devices because they say it is not valued enough to be worth the money. The spinner faces the biggest issues with it, if he does not want to process thick yarns or dark colours.

Afterwards, the cotton might be dried to processing moisture. There are two important moisture depen- dencies in cotton. First the cleaning of the cotton is better to do with a lower moisture content. In contrast, with less moisture the strength of the fibre lowers and therefore more fibres get damaged while processing. Hence, to have both, clean cotton and obtained fibre length, the moisture content has to be held at a com- promise between the two. [AG01] The value differs be- tween saw-ginning and roller-ginning. These two ma- chines are briefly presented below.

Gin stand

In India, Double Roller Ginning machines are mainly used with a market share of 95%. Another machine is the saw gin which generates a much higher through- put; however, it plays only a minor role in India. The reason for this is the quality of the cotton produced with this machine. Due to the process of sharp saw teeth dragging sensitive cotton fibre, damage occurs in the fibre length. As a result, the fibre output is more uneven, the short fibre content is significantly higher, and naps can develop. Therefore, long staple cotton is particularly unsuitable for saw gins. [Sha14]

To make roller ginning more competitive with saw ginning in terms of output, high speed roller ginning has become increasingly popular in recent years. As the name suggests, the idea is to combine the fibre-protecting properties of roller ginning with the production speed of saw ginning. Research shows significantly better fibre qualities in terms of length and short fibre content for the high-speed roller ginned fibres. However, higher trash contents were also found in these mills.

One major difference identified between Indian spinning mills and current literature is the moisture con- tent, which has been already mentioned above. The moisture content of up to 12% at the beginning of the process and thus higher than the values from the literature. Additionally, the moisture content is not measured with the help of a device but by the touch of an experienced operator in the factories visited in India as part of the project. The ginners indicated that a moisture content of 12% is ideal due to the high surface temperature of the washing machine and immediate ginning after the feeding machine. However, Pelletier et. al. claim that such a high moisture content is particularly harmful to the colour of the cotton as it reduces the Rd and b+ values. It can also cause the fibres to disintegrate and eventually dissolve.

Results and Implementation

Based on the onsite visit and reviews carried out of the ginning mills, a list of suggestions for improvement of conditions in a ginning mills were developed. The recommendations are divided into approaches for quick improvement with less effort and long-term measures. Following measures are suitable for quick improvements:

- Fire safety

- Accidental safety

- Roller (often called Washer) material

- Strapping the cotton bales

- Blending of the cotton

- Improvement of air quality in the ginning gill

- Inhouse quality testing

- Traceability of cotton in the ginning mill

- Knowledge distribution

- Moisture-dependent pre-sorting

- Process Step-dependent moisture regulation of the cotton

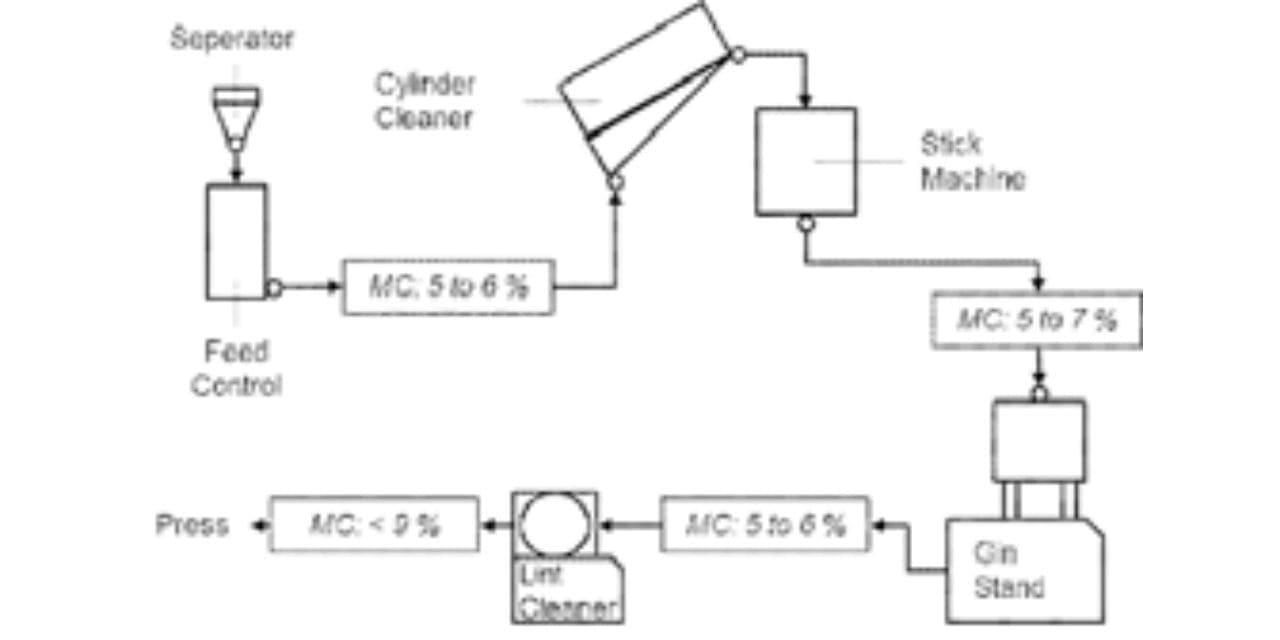

To achieve a more sustainable development, three long-term measures were identified. These are “New Ginning Mill Generation”, “Design 4 Recycling” and “Implementation of Industry 4.0 in Ginning Mills”, which will be discussed in more detail below. This re- sults out of the found machines at the ginning mills and the best moisture content at these levels of production (cf. Figure 2).

Figure 2: Recommended moisture content (MC) in the ginning plant

New Ginning Mill Generation

The task of a new ginning mill generation is to significantly increase the material throughput and to remain at least as gentle on the fibres. The data collection showed that fibre residues remain on the cores. On the one hand, this reflects that the fibre length is not completely preserved, and on the other hand, it also inhib- its oil extraction. Seed coat neps are another problem. These reduce the cotton quality and show that the ginning process window is not ideal. Besides, Double Roller gins should be completely covered as saw gins are already, to reduce the dust and short fibres flying in the ginning mill. This massively improves the health of the operators as well as the risk of fire and explosion. Moreover, a moisture control system directly optimizing the cotton water absorption and moisture level should be worked out for an even higher quality and process reliability.

Design 4 Recycling

An important step to achieve a more sustainable pro- cess of cotton production is product design according to the Design 4 Recycling approach. This is a holistic approach that takes into account the recycling of the end-of-life product as early as the product development stage. With the high-quality sustainable cotton product envisaged in the project, this market can po- tentially be served. It is necessary to adapt the ginning process to the requirements of Design 4 Recycling and to provide the corresponding proof.

Implementation of Industry 4.0 in Ginning Mills

In order to operate ginning mills more efficiently, In- dustry 4.0 as a case needs to be evaluated for the ginning mills. Especially the need to implement Industry 4.0 in export-oriented units will help to yield a better quality and longer as well as undamaged fibres in a production caring all safety norms. Implementation of sensor-actuator systems by means of retrofitting on existing machines, creation of digital environments, which can be linked to the spinning mills, can be explored. Essential basis is the collection of data about fibre quality and processing conditions. The use of Internet of Things (IoT) to connect multiple ginning mills at a macro level within the cotton supply chain will help reduce dependability on market and crop swings. This initiative will help establish a Ginning 4.0 program for ginning companies, which will help them integrate seamlessly with programs in spinning mills. Essential will be the collection of data about fibre quality and processing conditions. With these data process control can be actively and automatically driven, machine set their settings by their own and the process is only man- aged and controlled by the operator.

Possible shortages of skilled workers can be prevented by Industry 4.0. Processes become more transparent and easier to understand for the machine operator. The employee is supported in his/her work and does not need years of professional experience. The training for the Industry 4.0 in ginning should be provided by the solution developer for ginning mills or a general country wide training should take place by an economy independent institution for an easier market access.

Conclusion

In summary, it can be said that the quality of the cotton manifests itself in various characteristics and depends significantly on the machines chosen for production. Therefore, the value of clean and high-quality cotton should be seen and paid at all stages to archive best possible results in the garment. The moisture content was identified as particularly relevant here. Differences between the various ginning machines were discussed in terms of how they affect the quality of the cotton. Based on the results of the study, measures to achieve improvements in the ginning mills were identified. These are divided into two categories, on the one hand measures that require little effort and achieve quick improvements, and on the other hand long- term measures. These are presented and discussed in more detail regarding the sustainability of the cotton production. For an ideal implementation, the quick improvements should be carried out first and then be followed by the more long-term measures to ensure a higher quality of cotton in the long term and to make the production of cotton more sustainable.

Acknowledgement

The Institut für Textiltechnik wants to thank the Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH for the cooperation and implementation of this project and the Federal Ministry of Economic Cooperation and Development (BMZ) of Germany for the funding to be able to archive those results.

References

[AG01] Anthony, W. Griffin, A. Fibre Breakage at Cotton Gins: Causes and Solutions, 2001

[Cot18] Cotton Incorporated: The Classification of Cot- ton, 2018

[GH07] Gordon, S.; Hsieh, Y.-L.: Cotton.

- Edition – Cambridge: Woodhead Publishing Limited, 2007

[GVW19] Gries, T., Veit, D.; Wulfhorst, B.: Textile Ferti- gungsverfahren.

- , überarbeitete und erweiterte Edition -München: Hanser, 2019

[MA94] Mayfield, W.; Anthony, W.: Cotton ginners handbook.

Rev. ed. Edition – Washington, D.C.: United States De- partment of Agriculture, Agricultural Research Service, 1994

[Sha14] Sharma, M. K. New Direction in Roller Ginning Industry, 2014

[Sta19] Statista: Baumwolle, 2019.

AUTHORS:

Justin Kuehn Stefan Schlichter Vanessa Berghoff Thomas Gries