Dr N.N.Mahapatra

B.Sc( Hons),B.Sc (Tech )(Bom)M.Sc ( Chem ),Ph.D ( Chem ),M.B.A( IMM,Cal)

C.Col FSDC ( UK),CText FTI ( Manchester ),Int Trg ( Australia)),Sen Mem ,AATCC (USA)

FIC ,FTA , FICS,FIE,FIIChE ,MISTE ( INDIA)

President

COLORANT LTD

3225,Phase IV ,

G.I.D..C.Vatva,

Ahmedabad-382445

Gujarat,India

Modal is a bio-based fibre made by spinning reconstituted cellulose from the beech trees . modal fibres were initially developed in the 1930 s for industrial uses in tyres ,conveyor belts and hose pipes .

A generic name for a modified rayon fibre that has high tenacity and high wet modulus . additional developments in Japan in 1951 by S . Tachikawa lead to the production of modal fibres. . It is quite similar to the polynosic used in older days because of highest wet modulus . In handle and appearance the fibre is somewhat similar to a good quality mercerised cotton . Modal is a new kind of natural fibre developed by Austrian Lenzing Company . Modal is the registered trademark of Lenzing AG , an Austrian company specializing in textiles and fibres . , particularly natural fibres made from cellulose . Lenzing modal has been providing pure softness next to skin for more than 40 years , a record no other fibre can equal. The fibre cross-section illustrates its soft structure.

Because of its superior properties , Modal has gained a lot of popularity in the developed world during the last three decades , with the consumption expected to touch 40,000 tonnes this year , says Johann Leitner , Head of Product Development and Technical Marketing for Lenzing Fibres . A significant part of this growth has come from the replacement of polynosic fibres whose production by Japanese companies has been stopped due to economic problems .

Lenzing started promoting modal in India only in the late 1990 s , when economic liberalisation became effective and import duties were brought down .

Now the consumption in India is 4000 tonnes till 2007 . Birla Cellulose is offering Birla Modal . Modal as defined by The International Bureau for the Standardization of Man Made Fibres ( BISFA ) is a distinct viscose fibre genre , which has high wet modulus and satisfies a minimum value of tenacity in the wet stage at 5 % elongation.

Manufacturing process – Modal is a speciality fibre , produced solely by the Austrian company , Lenzing AG .It is made exclusively from the beechwood pulp and consists of 100 per cent cellulose . Naturalness plays a key role in Lenzing Modal . The fiber is made from beech wood , a natural raw material . The pulp used for fibre production is made by Lenzing to guarantee consistent and reliable quality .The secret of the fibres success is pure beech wood . The cellulose produced at Lenzing is extracted from indigenous woods and used for the production of Lenzing Modal.the quality is guaranteed through the control of the whole manufacturing process – from wood to fibre . The standard of the raw material is decisive for the quality and makes Lenzing Modal so unmistakable .

The in – house pulp production department uses beech wood from the region . The raw material helps promote the quality of Lenzing Modal.many of the fibers other characteristic properties are associated with beech wood making Lenzing Modal so unique . the pulp and fibre production are conducted in accordance with the principle of sustainability . chemicals and secondary products which occur during the production process are sold as valuable substances . one example of this wood sugar which is further processed to sweeteners .

The standard Lenzing Modal fibre is available in 1.5 D x 39 mm and 1.7 D x 39 mm and 50 mm . The fine Lenzing Modal is also available in a micro variant. . This extra fine fibre makes textiles even lighter . It feels like ‘ skin on skin ‘ . You can hardly feel MicroModal – it is so pleasant . The MICRO is available in 1.0 D x 34 mm and 39 mm .

Properties of Modal fibre – Modal is currently called the new wonder fibre .This fibre combines the benefits of natural fiber and the fantastically soft feel of modern microforms . it is about 50 % more hygroscopic , or water – absorbent , per unit volume than cotton is . it is designed to dye just like cotton , and is color – fast when washed in warm water . Mint and preserves these properties even after many washing cycles . Modal fibres are dimensionally stable and do not shrink or get pulled out of shape when wet like many rayons. They are also wear resistant and strong while maintaining a soft , silky feel . Modal fabric has softness , good drape and is comfortable for wearing . Modal fabric has good moisture regain and air permeability which is often considered better than cotton fabric , it is a good material for exercise clothing and health suit. , which can serve to benefit physiology circulation and health of the body. The natural softener of Lenzing Modal means fabrics remain pleasant to the touch even after repeated washing . hardening of the fabric , which occurs as a result of limestone deposits and traces of detergent , becomes a thing of the past with Lenzing Modal. Modal fabric has level up surface , fine and smooth and velvet , which have the effect of natural silk . The yarn has the character of high strength . The fabric has good softness and brilliant lustre . The effect of the finished Modal garment is very good , and the form is steady. The garment maintains anti-crease properties and has relatively easy care . With the hygroscopity of Cotton and the luster of Silk , it remains soft and lustrous after several washes.

Textiles made from modal do not fibrillate , or pill , like cotton does , and are resistant to shrinkage and fading . they are smooth and soft , more so than even mercerized cotton , to the point where mineral deposits from hard water , such as lime , do not stick to the fabric surface . like pure cotton , modal should ideally be ironed after washing .

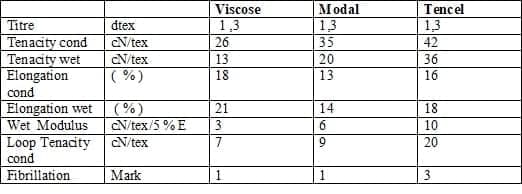

Comparison of different Cellulosic Fibres

Birla Modal absorbs moisture more quickly than cotton and is doubly as effective as cotton even after repeated washes , it remains as supple and absorbent as the day it was made.

Blends of Modal fibre – Fabrics made of 100% Modal and blends of Modal/Cotton ,Modal/Spandex , Modal/Lycra , Modal/Wool , Modal/Silk , Modal/Rayon and Modal/Synthetics .are now being used in India for a variety of products .

It is manufactured by Zhangjiagang Beta Manufacturing & Textiles Co Ltd , Jiangsu , China. Since last 10 years they are doing knitting , dyeing and finishing of Modal fabrics.

The fibre is now being spun into yarn by a number of Indian companies , such as RSWM , Bhilwara manufactures Cotton/Modal blend in 50/50 ratio and count is 2/30 . It can be yarn dyed in package form or piece dyed in fabric form. Raymond , Chindwara makes polyester /modal suiting 67/33 blend which is bleached and dyed by Snow White process developed by Rossari Chemicals, Mumbai.

Lenzing Modal is particularly well suited to blends with cotton since both fibers have similar properties. The fibre cross –section of Lenzing Modal is similar to that of cotton ensuring that Lenzing Modal is an optimum blending partner . Lenzing Modal cannot only be blended with cotton to get optimum results. Like no other cellulose fibre , Lenzing Modal harmonizes with other fibres – in a simple and un complicated manner. In particular , the dyeing performance of Lenzing Modal emulates that of cotton . It is like perfect partnership . The properties of both of these fibres – Lenzing Modal and cotton are very similar . In particular the dyeing behaviour of Lenzing Modal enables tone – on – tone dyeing in the blend since Lenzing Modal has the same deep dyeing effect as cotton . No other cellulose fibre produces comparable results . Another asset is the fact that Lenzing Modal can be mercerized without any difficulty – an absolute must with blends with cotton . In blends with cotton , Lenzing Modal improves the yarn regularity and helps to attain a better fabric surface .

Though cotton remains an old favorite blend partner , Birla Modal blends beautifully with almost all textile fibres. Following are the fabric constructions

- warp – 50 s 100% polyester.

Weft – 60 s 100% Modal.

2. warp – 2/50 poly/modal 50/50

weft – 2/50 poly/modal 50/50.

3. warp – 2/60 cotton /modal 50/50.dyed

Weft – 40 s cotton/modal 50/50 dyed.

4. warp – 2/36 cotton/modal 50/50.

Weft – 2/36 cotton/modal 50/50

5. modal lycra 96/4

count 40 s modal x lycra

Uses of Modal fibre – Lenzing modal is the perfect fibre for fabrics worn next to the skin – for day and night , sports and active wear . Among the areas of application which have found favour are knitwear and woven inner and outer garments . In home textiles , it is used for a variety of terry – cloth products . if you are looking for exceptional softness then look no further than lenzing modal .It is used in jersey and other fabrics. China manufactures flatlock stitched underwear made out of Modal fabric. In the United States , pure Modal has begun being used in household linens such as towels , bathrobes and bedsheets , bed bath and beyond . Modal is also the main textile used in manufacturing of panties , sleepwear , casual line , clothing lines and is available in all leading shopping malls. Modal fibres have found a wide variety of uses in clothing ,outerwear and household furnishings.