Spinning

This spinning is about forming yarn from fibers. For forming fibers from a fluid, see Spinning (polymers).

Spinning is the twisting technique where the fiber is drawn out, twisted, and wound onto a bobbin.

Spinning Process

The yarn issuing from the drafting rollers passes through a thread-guide, round a traveller that is free to rotate around a ring, and then onto a tube or bobbin, which is carried on to a spindle, the axis of which passes through a center of the ring. The spindle is driven (usually at an angular velocity that is either constant or changes only slowly), and the traveller is dragged around a ring by the loop of yarn passing round it. If the drafting rollers were stationary, the angular velocity of the traveller would be the same as that of the spindle, and each revolution of the spindle would cause one turn of a twist to be inserted in the loop of yarn between the roller nip and the traveller. In spinning, however, the yarn is continually issuing from the rollers of the drafting system and, under these circumstances, the angular velocity of the traveller is less than that of the spindle by an amount that is just sufficient to allow the yarn to be wound onto the bobbin at the same rate as that at which it issues from the drafting rollers.

Each revolution of the traveller now inserts one turn of twist into the loop of yarn between the roller nip and the traveller but, in equilibrium, the number of turns of twist in the loop of yarn remains constant as the twisted yarn is passing through the traveller at a corresponding rate

What Is Spinning?

Textiles are all around us. We wear them, use them when we sleep, and decorate our homes with them. But, have you ever thought about how they are made? One important step is spinning the yarn. Spinning is the process of taking textile fibers and filaments and making them into yarn. For thousands of years, people spun natural fibers into yarn by hand. Today, spinning involves many methods and different machines, depending on what kind of yarn is being made.

Before we discuss how spinning works, let’s review some basics. Fibers are short, natural hairs that come from plants like cotton and animals like sheep. Filaments are long continuous single strands. Silk is a natural filament, but most filaments are synthetic or man-made materials, like polyester and nylon. Converting fibers and the substances that form synthetic filaments into yarn involves different methods of spinning.

Basic Process of Spinning Yarn

First, let’s look at the basics of spinning, which can be done with very simple tools. To make a natural yarn, you gather cleaned and prepared natural fibers like wool or cotton. Using a tool called a spindle, a rounded stick with tapered ends, you pull the fibers by hand onto it as the spindle twists. To aid the process, the spindle is weighted by something called a whorl, a small, round stone or piece of wood which allows the spinning to be maintained at a regular speed. The process of pulling and twisting results in a piece of yarn.

Spinning Natural Fibers

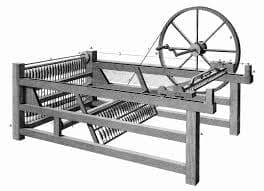

This basic spinning process was used for natural fibers. It’s how the process worked for thousands of years. Then, advances in tools and technology made spinning more efficient. In 1828, a machine was invented that allowed a method called ring spinning to mechanize the process. During this process, hundreds of spindles are mounted vertically on a machine that spins fibers into yarns.

Ring spinning is still the way many fibers are turned into yarn, but in the 20th century another method was invented. Today, some yarns are made through rotor or open-ended spinning. In this method, the fibers are fed into a rotor and blown with air into a system that turns them into yarn without using a spindle. Yarns created by rotor spinning tend to be bulkier and heavier than those made by ring spinning.

Spinning methods

Spinning is the process of drawing out and twisting fibres to join them firmly together in a continuous thread or yarn. Spinning is an indispensable preliminary to weaving cloth from those fibres that do not have extreme length. From early times through the Middle Ages, spinning was accomplished with the use of two implements, the distaff and the spindle. The distaff was a stick on which the mass of fibres was held. The drawn-out length of fibre was fastened to the weighted spindle, which hung free. The spinner whirled the spindle, causing it to twist the fibre as it was drawn from the distaff. As a length was drawn out, the operation was halted, the new yarn wound on the spindle and secured by a notch, and the operation was repeated. The spinning wheel, invented in India and introduced to Europe in the Middle Ages, mechanized the process; the spinning of the wheel supplanted the whirl of the weighted spindle, and after each operation the spinner wound the new yarn on the spindle

Modern spinning

In modern spinning, slivers or rovings are fed into machines with rollers that draw out the strands, making them longer and thinner, and spindles that insert the amount of twist necessary to hold the fibres together. Tightness of the twist determines the strength of the yarn, although too much twist may eventually cause weakening and breakage. When the spirals formed by twisted yarns are similar in slope to the central portion of the letter Z, the yarns are described as Z-twist; when the spirals conform in direction to the central portion of the letter S, the yarns are described as S-twist. Crepe yarns,

Reeling and throwing

Reeling is the process of unwinding raw silk filament from the cocoon directly onto a holder. When several filament strands, either raw silk or synthetic, are combined and twisted together, producing yarn of a specified thickness, the process is called throwing.

Yarn packages

The intended use of a yarn usually determines the packaging method employed. Bobbins are wood, cardboard, or plastic cores on which yarns are wound as they are spun, and they have holes in their centres allowing them to fit on spindles or other holding devices. Spools are cylindrical, with end flanges. Cones, having a conical-shaped core, produce a package of conical shape; tubes, with cylindrical-shaped cores, produce cylindrical packages.

Types of yarn

1. Single yarns

2. Ply yarns

3. Cord yarns

4. Novelty yarns

5. Textured yarns

6. Stretch yarns

7. Metallic yarns

Production Of Fabric

Fabric construction involves the conversion of yarns, and sometimes fibres, into a fabric having characteristics determined by the materials and methods employed. Most fabrics are presently produced by some method of interlacing, such as weaving or knitting. Weaving, currently the major method of fabric production, includes the basic weaves, plain or tabby, twill, and satin, and the fancy weaves, including pile, Jacquard, dobby, and gauze. Knitted fabrics are rapidly increasing in importance and include weft types and the warp types, raschel and tricot. Other interlaced fabrics include net, lace, and braid. Nonwoven fabrics are gaining importance and include materials produced by felting and bonding. Laminating processes are also increasing in importance, and fairly recent developments include needle weaving and the sewing-knitting process.

Conclusion

The above spinning methods in textile manufacturing process only conduct the production of yarn by textile fiber. This semi-finished products are further managed with other different methods such dyeing, weaving, garment manufacturing and much more.

Referance

Advances in yarn Spinning Technology books