- Introductionss

Banaras (Varanasi), a holy city of Uttar Pradesh, is a centre for brocade and hand-made textiles and saris since ancient times. In Banarasi Saree weaving many types of exclusive weaves are woven on handlooms. These handloom are mounted with different kinds of hand operated dobbies and Jacquards. In this famous weaving the word brocade is derived from the Latin word “brochus“denoting to transfix. The exquisite fabrics, so much appreciated all over the world, are produced by weaving with warps and weft threads of different colours and often of different materials. It appears from ancient texts that in early days gold and silver wires were drawn out to such fineness that they could be woven into fabrics of pure gold and silver. Silk was added later to give colour and body to the textile. Now gold or silver wires are used as a special weft twisted along with the silk. Generally Banarasi work are carried out in whole Banaras and nearby villages of this city. Whereas out of whole city the main areas are focused for Banarasi weaving are like Peeli Kothi, Madanpura, Saraiya, Bajhadhiya, and Lohta. Currently, there are approximately forty thousand people engaged in Banarasi weaving including weavers, dealers and dyers. The main product of Banarasi handloom weaving is the saree.

- Historical Background

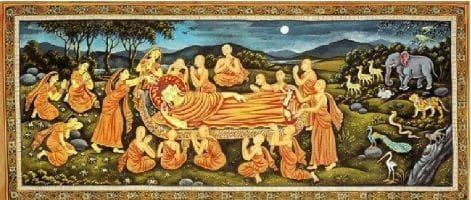

The brocade weaving centres of India developed in and around the capitals of kingdoms or holy cities because of the demand for expensive fabrics by the royal families or temples. The ancient centres were situated mainly in Banaras, Gujarat, Delhi, Agra and Murshidabad. Northern weavers were greatly influenced, so far as design and technique were concerned, by the brocade weaving regions of eastern and southern Persia, Turkey, Central Asia and Afghanistan. According to Buddhist literature, Varanasi fabrics were pleasant to handle, beautiful to look at and were greatly popular with rich and tasteful people all over the world. As per the legends, when Buddha attained Mahaparinirvana (Figure 1) his mortal remains were wrapped in a Banaras fabric radiating with rays of yellow, red and blue colours.

Fig. 1: Buddha’s Fabric Design

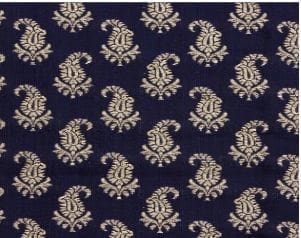

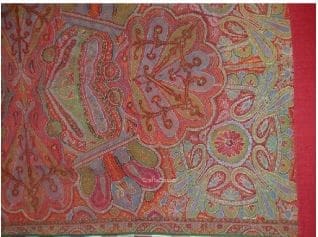

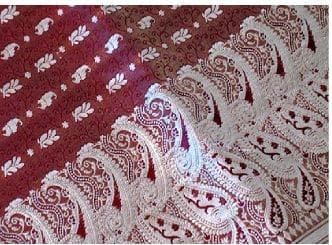

Varied patterns displayed in the Ajanta murals of the Gupta period are believed by some art historians to represent some brocade specimens also, and the floral designs, animals and birds motifs and geometrical patterns have close affinity with the early brocade motifs. In Kashmir the brocade art was developed by Sultan Zin-ul-Abidin (A.D. 1459 -1470) in the fifteenth century. He encouraged the interchange of weavers with Iran. A large number of foreign weavers/artisans assembled in the royal workshop of Kashmir. There is a remarkable resemblance between Banaras brocade and the Jamawar shawls of Kashmir as they drew pattern motifs from a common source. Jahangir was also a great expert of brocades.

Fig. 2: Banaras brocade Fig. 3: Jamawar shawls

Every social or religious group had its own norms regarding the colour, design, and material of their garment. Hindus liked bright coloured silk in colours patterns like red, yellow & orange (Figure 4 &5).

Fig.4: Red Pattern Fig.5: Yellow Pattern

Mashrub or mixed fabric was used mostly by peoples in colours like lavender, sky blue (Figure 6), white and magenta-blanket.

Fig. 6: Blue Pattern

- Raw material

There are two broad classes of Brocades: .Brocades of pure silk and cotton blends, and Zari brocades with gold and silver threads. The most important material used in brocade weaving is silk. It facilitates lovely waves, is durable, strong, fine and smooth. There are several varieties of raw silk of which the main ones used for brocades are Tanduri, Banaka and Mukta. Tanduri is imported from Malda and other places. Benga Banaka is a thinner and finer variety and is mostly used to weave soft fabrics such as turbans and handkerchiefs. Mukta is a coarse and durable silk used for kimkhabs, as fine silk does not withstand heavy gold patterns. Brocade of pure silk and cotton blend (Figure 7)

Fig. 7: Brocade of silk & cotton Blend

- Silk: The basic raw material of many types of brocade is mainly mulberry silk thread. Apart from the inherent beauty of silk brocades, the fact that they were made from non-indigenous materials added to their value. Japanese and Chinese silk threads were renowned for their superior qualities of evenness and shine.

- Zari: Zari is the gold and silver thread used in Indian brocades. Zari is of two types – Badla is made of flattened gold and silver wire. Kalabattu is a thin silver or gold wire that is wound around silk or cotton and now even rayon thread.

- Fabric types

Brocade types fabric can be classified into two types. (1) Loom finish – Loom finished fabrics are saris, odhini, patkas, pankhas, curtains etc. (2) Yardage- Yardage is usually used for dress material, upholstery and curtains.

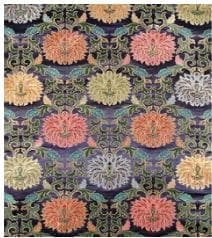

- The best known brocade fabrics were kamkhwab (Figure.8) or kinkhab (Figure 9). Their main centres were Varanasi, Ahmedabad and Surat. Their splendour, elegance and cost gave them their name, which means, ‘something a person cannot dream of if he has not seen it’ (Kam: little, khwab: dream; kin: golden in Chinese). Its specialty is the profuse use of gold and silver thread, such that the silk background is barely visible. It is mainly used for ceremonial robes, hangings and furnishings.

Fig.8: Kinkhab Fig. 9: Kamkhwab

- Weaving process

The weaving of these Banarasi sarees is observed at Banaras and currently, approximate forty thousand active weavers are found along with them are active dealers, dyers, designers and supplementary support providers. Before the weaving, the silk yarn undergoes few steps and then the weaving begins. The Jacquard card, spools and beam is set up with suitable color yarns and weaving is done.

- Jacquard cards – Saree designs

The desired design that is to be worked on the saree is drawn on a sheet of graph paper (Fig.10). This graph sheet becomes the reference to punch the cards (Fig 11). They are made to a set of cards (Fig 12) that will be tied together and loaded to the jacquard machine.

Fig 10: Design on Graph Paper Fig 11: Punching of Card Fig 12 : Lacing of Pattern Card

- The yarns

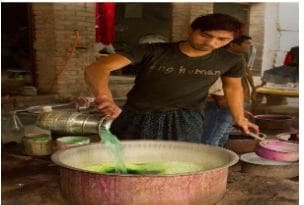

- The raw silk yarns (Fig 13) are processed they are dyed with suitable colours. It follows something that of a tie and dye process (Fig 14). Series like chiffon undergo this tie and dye process. The yarn after the initial stages of processing and dyeing (Fig 15) process with tub-dip method (Fig 16). It is segregated to undergo warping and weft processes.

Fig. 13: Raw Silk Fig. 14: Tie &Dye Process

Fig. 15: Dyed Yarn Fig. 16: Tub – Dip Method

- The threads are spun to spools with the help of spinning wheel to prepare the spools to load to the fly shuttle, the threads that fill up through fly shuttle is called weft (Fig. 17,18 &19).The weft threads are wound on weft pirn with the help of charkha. The warp threads are got ready by spreading them lengthwise creating pulls and is rolled to beam ( Fig 20), which is later fixed to the loom (Fig 21).

Fig. 17, 18 & 19: Thread is loaded on Pirns by the help of Charakha and Pirn inserted in Shuttle

Fig. 20: Warp on Warp Beam Fig 21: Beam Get-up on Loom

- The Weaving

The loom is set up with the threads and the process of weaving is began before which the jacquard cards are fixed to the jacquard machine and following the cards the threads are pulled and the desired design and the saree is weaved. In weaving warp, craftsmen build the base that runs of the required length. Once the punched cards are prepared those are spun with altered threads and colours on the loom allowing to design and are paddled in an orderly manner that the main weaving picks up right colour and pattern to produce the design and weave as well. The Figure 22 and 23 reveals the photographs of Jacquard and Banarasi weaving.

Fig 22: Jacquard Machine Fig 23: Banarasi Weaving

- Motifs and Pattern

- When this form of fabric was introduced to India, local artisans adapted it to the predominant Hindu culture that was prevalent by creating popular motifs of the paisley floral pattern (like marigold, jasmine etc.) Fruits design (like mango etc.), animal pattern (like elephant, horse, dears etc.),bird depiction (peacock, parrot etc.) and sun, moon, stars. Most Banarasi saris reflect ancient Mughal influence which is seen in the motifs used like floral and foliate motifs.

- Other motifs used are village Scenes, fairs, designs inspired from architecture of temple and mosque, etc. The edge of the sari border is a characteristic of Banarasi Saris.

- Another celebrated pattern of Banaras brocade is Jaal or net design, also known as Jangala. It is a rich pattern covering the ground of the fabric and owes its origin to Turkish brocades. The Banaras Jaal was very delicate. In the Jaal, flower, bird or animal forms were enclosed within a net-worked form evolved from arch, square or other geometrical forms.

- Flowers and creepers were interlocked, filling up the ground. The Hyderabadi Jangala was introduced to the weavers of Varanasi on demand of the court of Nizam of Hyderabad. Another adaptation

from the Persian prototype which became the specialty of Varanasi is Latifa buti, probably named after its designer Latif Mian.

- Religion too provided a variety of decorative motifs. Varanasi being a religious centre had a large demand for cloth woven specially for temples and devotees. Along with floral patterns, auspicious symbols and figures of deities were also used as motifs.

- In present days

- More contemporary designs draw inspiration from the past and fuse it with modern influences such as animal, birds, and geometric and floweral design patterns (Fig 24, 25 and 26).

Fig.24: Peacock Pattern Fig. 25: Fruit Design

Fig. 26: Geometrical Design

- Banarasi brocade sarees can be divided into five categories:

- Jangala saree

Jangala saree make use of silk thread. Pattern and motifs of vegetation are spread throughout the fabric with gold and silver flowers (Fig 27)

Fig. 27: Jangala Saree

Fig. 27: Jangala Saree

- Tanchoi saree

Tanchoi saree make use of the gold or silver thread, Zari are commonly worn for wedding ceremonies.

The motifs are created by using extra weft (Fig. 28).

Fig 28: Tanchoi Saree

- Tissue sarees

Tissue saree make use of gold or silver Zari in weft. Tissue sarees are preferred as wedding saree by the affluent.

Fig. 29: Tissue Saree

- Butidar sarees

Butidar Saree make use of gold, silver and silk thread. It is common to find the end panel consisting of a row of arches with a burst of silver.

Fig 30: Butidar Saree

- Cut work sarees

Cut work saree are made using warp threads with cotton and regular weft to create design. Patterns are created by cutting extra loose hanging weft threads.

Fig. 31: Cut work Design

- Colour

Colour plays a vital part in weaving brocade.• The charm and subtle beauty of the brocade depends upon colour synchronisation.• Earlier, vegetable dyes were used during weaving. These produced fast colours, lasted for almost a generation.• Nowadays, chemical dyes have gained popularity as they are cheaper, less time-consuming.

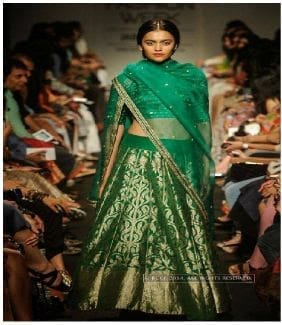

- Market

Brocade has always been a special fabric catering to the needs of the wealthy. Banarasi Brocade and sarees are immensely popular across the globe. Today Banarasi brocade is once again in great demand. The pattern and motifs used to create brocade work are also being incorporated into western garments today. This has been seen on international as well as Indian runways. The fusion of two worlds create a garment that is both, lavish and contemporary. Brands like Sabyasachi and Raw mango incorporate these textile in their designs. The market of Brocade has also grown for the fashion wear, traditional look and multy use of like a celebrity brand fabric with many special features. Fashion word market also copying this designs after mixing with other modern pattern and creating the fusion of new innovations.

Fig. 32: Brocade Design on Fashion

- References.

- Watson, J. Forbes. 1873. Collection of the Textile Manufactures of India’ (Second Series). London: India Museum.

- Singh, Martand et al. 1982. The Master Weavers. Bombay: Subrata Bhomick.

- Mohanty, Bijoy C. 1984. Brocaded Fabrics of India, Vols I and II. Ahmedabad: Calico Museum of Textiles.

- Kumar, Nita. 1988. The Artisans of Banaras: Popular Culture and Identity, 1880–1986. Delhi: Oxford University Press.

- Dhamija, Jasleen and Jyotindra Jain (Eds.). 1989. Handwoven Fabrics of India. Ahmedabad: Mapin Books.

- Ali, Yusuf. 1900. A Monograph on Silk Fabrics Produced in the North-Western Provinces and Oudh. Allahabad: N.W.P and Oudh Government Press.

AUTHORS :

- S. Barhanpurkar,Assistant Professor, SVITT, SVVV, Indore

- B. Tanvi, Tirathbai Kalachand School Indore,

- 4.Y. Agrawal Assistant Professor, SVITT, SVVV, Indore.