Automatic Storage and Retrieval Systems (ASRS) can play a vital role in improving material flow and increasing production performance in any textile factory, be it for weaving, knitting, processing or garmenting.An optimum material handling system reduces the material transportation time, and ensures that the required materials are transferred to the point of use safely, without any error or damage. In a sewing department, for instance, a material handling system may be customised based on the line layout, better ensuring smooth movement of fabric rolls from one workstation to another, or for storing or cutting.

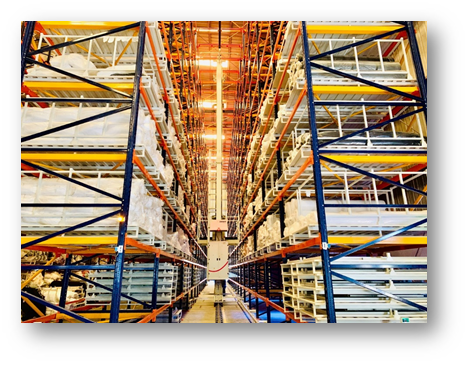

Sieger’s ASRS (Automatic Storage and Retrieval System) is designed to automatically store and retrieve grey and finished textile goods in various forms such as rolls, bundles etc. Storage and retrieval is quick and based on the demands of production.

As a market leader with 25 years of expertise in the manufacturing of textile machinery, Sieger leverages its strong R&D and world-class manufacturing set-up to provide the latest automation solutions for fabric storage and handling.

Sieger’s ASRS can alleviate many pressing issues faced by textile mills. For example, the Sieger ASRS can

- Reduce operations bottlenecks by:

- Mitigating operating space constraints

- Providing timely service to the garment division for emergency orders

- Reducing the need for other material handling equipment

- Overcoming labour scarcity by:

- Reducing labour requirement

- Also reducing the need for a highly skilled work force

- Help with inventory control by:

- Distributing material as per age, to reduce aging stock

- Overcoming the difficulty of locating the necessary material or identifying the right fabric roll for the right job

- Eliminating an unknown stock situation and lack of inventory control

- Improve quality

- Always supplying fabric with the right specification

- Managing complications in handling multiple samples in multiple standards for multiple buyers

- Reducing staining and/or wastage of processed fabric

- Enhance productivity by

- Reducing idle time in garment line for want of ready-to-stitch fabric

- On-time supply of grey material for preparation and dyeing

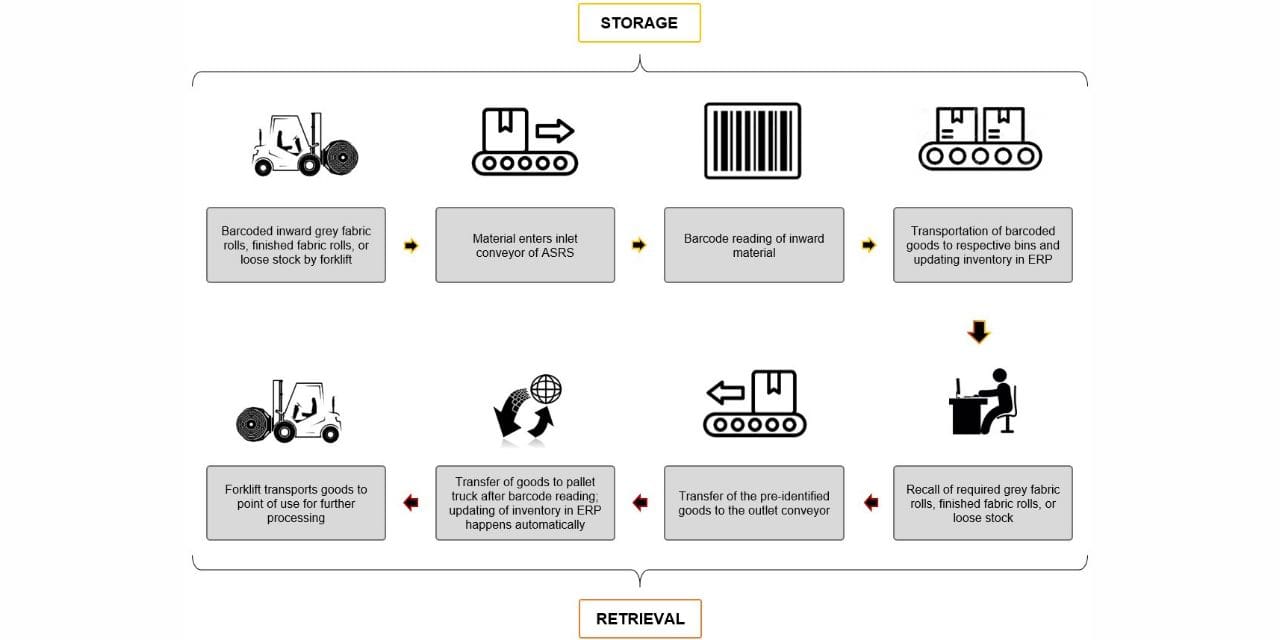

Material flow with ASRS Storage

- Bring in barcoded grey fabric rolls, finished fabric rolls, or loose stock by pallet truck

- Feed material into the inlet conveyor of ASRS

- Barcode reading of inward material

- Transportation of barcoded goods to respective bins and updating inventory in ERP

Retrieval

- Recall of required grey fabric rolls, finished fabric rolls, or loose stock

- Transfer of the pre-identified goods to the outlet conveyor

- Transfer of goods to pallet truck after barcode reading; updating of inventory in ERP happens automatically

- Forklift transports goods to point of use for further processing

Features of ASRS

- Live warehouse efficiency monitoring

- Laser guided movement for accuracy and obstruction detection

- 750 kg capacity fork

- Barcoded pallets, which are directly linked to ERP

- Hydraulic buffers for additional safety

- The warehouse management system (WMS) offered by SIEGER along with the ASRS enables complete material inventory control. This translates into direct savings in manpower while increasing efficiency in material retrieval and identification

Modules offered

- Conveyors: chain/overhead/roller

- Stretch wrapping

- Turn tables

- Single and double deep ASRS

- Radio shuttle retrieval systems

- Racking systems

- Storage pallets

Sieger’s ASRS is used in conjunction with the following for storage and handling in weaving, knitting, processing, and garments:

- Pallets to store fabric rolls

- Fabric buffer storage system

Pallets to store fabric rolls

Fabric rolls are stored in a pre-fabricated steel structureknown as pallets so that they may be handled effectively.These pallets are custom designed as per customers’ requirements based on the volume and size, which enablesthe transferof the fabric rollswithout any damage to the fabric.

Fabric buffer storage system

Sieger’s fabric buffer storage helps makeproduction processes fast and smooth. Buffer storage areas or systems are used to temporarily store items that will soon be needed for production or orders.

If there is a shortage of material coming from the warehouse, production processes can slow down and that can be very costly. However, buffer storage solves this problem by quickly supplying fabric rolls to the cutting lines or order processing areas to prevent delays that might occur if fabric had to be transported from a further-away warehouse.Fabrics can be transferred automatically from the storage section to the cutting section without any manual intervention.Sieger’sfabric roll buffer storage system is anideal choicefor ensuring hassle-free deliveryof fabric rolls to the access point in a few seconds.It has up to 60% more storage capacity, when compared with conventional storing systems.This means thatthe space can be utilised effectively for goods and products needed for the production process.