Introduction:

Due to their ecological credentials and advantages like style, comfort, and versatility, wood-based textile fibres are predicted to rise at a rate of more than 5% yearly until 2022, which is why the textile sector is currently exploring for alternatives to cotton and fossil-based fibres. Additionally, wood-based fabrics are more breathable, better at controlling moisture, printable, and have colour retention from wash to wash. The most prevalent organic molecule in nature, cellulose serves as the foundation for both naturally occurring and artificially created cellulosic textile fibres. All plant-based fibres must be separated from the plant components that aren’t utilized for the finished product. This is often accomplished through harvesting, separating from the chaff, and washing.

Bast fibre, also known as so-called phloem fibre or skin fibre, is a type of plant fibre that is derived from the bast or phloem, the inner bark of various dicotyledonous plants that surrounds the stem. Hard plant fibres, such as leaf fibres, are typically utilised for cordage or vegan leathers. Since wood fibres are stiffer and typically require an additional treatment to soften, they are obtained from trees, grasses, and bamboo. For viscose and lyocell, carbon sulphide and N-methyl morpholine-N-oxide, which is less hazardous than carbon sulphide, respectively, are used to solubilize sodium hydroxide. Regenerated fibres are made from natural polymers that have undergone chemical breakdown and have been reformed into fibres that may be spun and woven to make fabric. Green plants’ cellulose is a crucial structural element, and turning wood into soft fibres requires a lot of chemicals. A “closed-loop” manufacturing technique is now used by some firms to gather, recycle, and reuse chemicals.

Plate no 1: Viscose Process[3]

Wood-Based Fibers Market Analysis:

Globally, the market for wood-based fibres is anticipated to expand at a CAGR of 6% due to increased textile industry demand and growing consumer interest in its sustainability attributes. In the first 11 months of 2023, the textile industry in China had steady growth, but India’s sector accounts for more than 13% of industrial output and 2% of GDP. The textile sector in Japan is about USD 250 billion, while in 2023, Indonesia’s TPT exported goods worth USD 12.78 billion.

Plate no 2: Market Analysis of Wood Based Fibers[2

Wood Fibers:

Tencel, a synthetic fibre manufactured from cellulose, is also known as Lyocell. It is a very durable fabric that is used in industries to make bandages, abrasive materials, automobile filters, ropes, and protective clothing. Count Hilaire de Chardonnet produced the first cellulosic fibre for commercial use in 1889. The primary component of lyocell is cellulose, a natural polymer present in all plant cells. An amine oxide is utilised as the manufacturing solvent, water is used as the finishing agent, and any dyes that work with cotton and rayon can be used to colour lyocell fabrics. Recovery and reuse of the amine oxide used to dissolve the cellulose and set the fibre after spinning during production. A modified version of rayon called modal was created for industrial use in the 1930s. It doesn’t expand or shrink, and its sustainability depends on the manufacturer. Lenzing is dedicated to the use of closed-loop systems and wood from responsibly managed forests.

Difference:

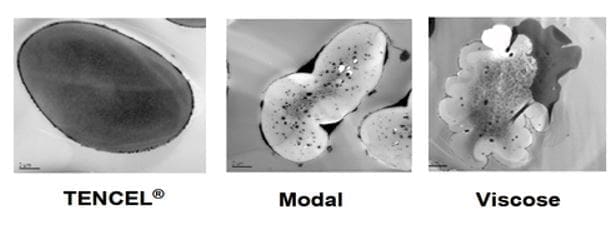

The fibre known as viscose in Europe and rayon in North America is the same fibre that is also known by the names modal and lyocell. They are made of removed, dissolved, and then realigned fibres of cellulose, the substance that gives plants their rigidity. These textiles’ favourable characteristics, including a natural next-to-skin softness, breathability, and effective moisture management, are due to their chemical composition, which is derived from plants. Similar techniques are used to create modal and viscose, but in order to create stronger filaments, modal fibres are given a different treatment after spinning. A plant-based fibre known as Lyocell is created from Eucalyptus trees that grow quickly in forests that are responsibly maintained. N-Methyl morpholine N-oxide (NMMO), a different solvent, is used to remove the cellulose from the wood. It is more convenient to filter and reuse this organic solvent in a closed loop, which is better for the environment. Because of the fiber’s more consistent internal structure, textiles have better moisture absorption and breathability.

Plate No. 3: Cross sectional Image of Tencel, Modal and Viscose[9]

Sustainable Way:

Known as TENCEL™ Lyocell, Modal, Cupro, Bemberg™, Lenzing™️ , EcoVero™️ , Viscose Fabrics, lyocell, modal, and viscose fibres are certified by the Austrian business Lenzing. TENCEL is a type of rayon manufactured from cellulose fibres obtained by harvesting wood pulp from Eucalyptus, Oak, and Birch trees. By spinning cellulose that has been reconstituted from beech trees, a form of rayon called modal is created. Although viscose must be produced using chemicals, which can result in the discharge of hazardous compounds into the air and waterways, EcoVero is frequently recognised as being sustainable. High environmental requirements are met in the creation of LENZING ECOVERO fibres, which are made from renewable wood sources that have been independently verified.

REFERENCES:

- Textiles from trees: What’s old is new again. Faculty of Science. (2019, February 11). Retrieved January 11, 2023, from https://www.mcgill.ca/science/channels/news/textiles-trees-whats-old-new-again-294430

- Altor, A. (2017, November 30). Rayon, viscose and modal are made from trees! Read your clothing labels!One Earth Body Care. Retrieved January 11, 2023, from https://www.oneearthbodycare.com/is-deforestation-hiding-in-your-closet/

- Bast Fibres Processing. (n.d.). Bast Fibres Processing. Retrieved January 18, 2023, from http://sff.arts.ac.uk/Fibre%20Processing/bastfibresproces.html

- Making fabric from wood – AllThings.Bio. (2017, May 25). AllThings.Bio. Retrieved January 11, 2023, from https://www.allthings.bio/making-fabric-wood/

- Viscose Rayon Manufacturing Process. (2020, May 9). Viscose Rayon Manufacturing Process. Retrieved January 18, 2023, from https://www.textilesphere.com/2020/05/viscose-rayon-manufacturing-process.html

- How lyocell is made – material, manufacture, making, used, processing, steps, industry, machine. (n.d.). How Lyocell Is Made – Material, Manufacture, Making, Used, Processing, Steps, Industry, Machine. Retrieved January 20, 2023, from http://www.madehow.com/Volume-5/Lyocell.html

- What Is Modal? — The Good Trade. (2021, March 8). The Good Trade. Retrieved January 20, 2023, from https://www.thegoodtrade.com/features/what-is-modal

- Wood as the latest fashion trend? Tree textiles could provide new opportunities for industry – Forest & Wood Products Australia. (n.d.). Wood as the Latest Fashion Trend? Tree Textiles Could Provide New Opportunities for Industry – Forest & Wood Products Australia. Retrieved January 16, 2023, from https://fwpa.com.au/wood-as-the-latest-fashion-trend-tree-textiles-could-provide-new-opportunities-for-industry/

- This wood-based textile fibre is made without chemical solvents – MaterialDistrict. (2018, August 13). This Wood-based Textile Fibre Is Made Without Chemical Solvents – MaterialDistrict. Retrieved January 25, 2023, from https://materialdistrict.com/article/wood-based-textile-fibre/

- TENCELTMLyocell, Modal & LenzingTM️ EcoVeroTM️ Viscose – All you need to know. (2022, May 17). Sew Me Sunshine. Retrieved January 25, 2023, from https://sewmesunshine.co.uk/blogs/sew-me-sunshine/tencel-lyocell-modal-cupro-bemberg-lenzing-ecovero-viscose-all-you-need-to-know