Abstract:

Medical textiles include woven textiles, non-woven textiles, braided textiles, and knitted textiles. Nonwoven medical textiles account for more than 60% of all medical textiles used, but they are as disposable as conventional medical textiles. Knitted fabrics are used in high-tech medical textiles such as artificial blood vessels, hernia patches, cardiac support systems, knitted medical expandable metallic stents, and tendon scaffolds, though they make up a small part of the medical textiles. Weft and warp knitting structures are two types of knitting structures. This article reviews some of the knitting structures and materials used in medical textiles, including non-implantable, implantable, extra-corporeal textiles, and healthcare and hygiene products.

Introduction

used in medical facilities for mass care and patient management. It is a brand-new area that combines textile manufacturing with medical science. Textiles with high-added-value textile structures and goods are known as medical textiles. Textile materials are extremely useful in the medical field. And, as technology advances, synthetic fibers are becoming more prevalent in medical textiles. Biodegradable fibers are currently being researched and manufactured for use in medical materials. Medical textiles are categorized into four groups, based on their structure: knitted fabric, woven fabric, braided fabric, and non-woven fabric. Nonwovens account for more than 60% of all medical textiles in use. Most medical textiles are almost disposable. Knitted, knit, and braided fabrics account for a smaller percentage of overall medical fabric. Knitted fabrics have a loose structure, strong durability, high porosity, and a versatile and changeable structure nature as compared to woven fabrics. Knitted fabric structures may also be modified to suit various needs. Medical textiles, especially high-tech medical textiles, benefit greatly from them. Medical dressings, bandages, padding for medical mattresses, surgical clothing, and other high-tech items are all made of weft-knitted fabric. Mattresses, wrapping fabrics, and surgical organs are all made from warp-knitted cloth. For wound closure (sutures) or replacements, the products that heal the body are used.

Knitted Medical Textiles

Knitted structures are widely used in the medical field for treatment, surgeries, implants, bandages, dressings, ligaments, etc. These structures are preferred majorly because of their properties. Due to the use of synthetic fibers, these structures can be tailored to impart the desired properties. Knitted Medical Textiles are classified into three categories according to their use, medical dressings, implantable textiles and healthcare and hygiene products.

Non-Implantable Textiles

Medical dressings have three functions: they insulate, avoid trauma, they bind medications to the wound, and they absorb liquids. When wound dressings encounter the skin, they must have the properties of good hygroscopicity, breathability and a high level of comfort. Knitted medical dressings have more extensibility, elasticity, fitness, and versatility than non-knitted ones. Weft plain stitch and rib stitch are commonly used in medical dressings for two-dimensional structures because of their basic knitting technology, high durability, and low viscidity. Aside from these, medical dressings make extensive use of three-dimensional structures such as weft multiply composites, weft knitted spacer fabrics, and warp knitted spacer fabrics. They frequently have absorbent layers for good heat and moisture transfer control. Cotton, viscose filament, alginate fiber, jute cell, and chitosan are among the products used in medical dressings. Yarns and filaments account for a large portion of the procedure’s short fiber loss.

In medical bandages, warp knitted structures such as pillar stitch and tricot stitch are progressively added. Glass fiber is used to knit the bandage on an Italian COMEZ crocheting unit. Because of its biocompatibility and degradability, water-soluble PVA fiber has a lot of potential in medical bandages. It was knit on a DR10 EWH double needle-bar warp knitting machine with an 18-gauge needle gauge.

Implantable Textiles

Implantable textile are a series of materials made of textile technology, which can be implanted into human bodies. It is flexible, biocompatible, and easy to weave. Implantable textiles mainly include artificial blood vessels, hernia patches, artificial ligaments, etc. It can be woven into various structures for use in the different parts of the body and different functions.

Artificial Blood Vessel:

Artificial Blood Vessel

For secure structures and high compliance, warp-knitted structures are commonly used to knit artificial blood vessels. Excessive extension, edge roll, and ladder rarely come to an end. Knitted on a double needle-bar warp knitting machine with more patterns and ground bars, an artificial blood vessel is formed. Tricot and atlas stitches are widely used. Polyester, polypropylene, polyethylene, polyurethane, polytetrafluoroethylene, and other synthetic fabrics are used in artificial blood vessels. Silk fibroin is also valued for its durability and strength. Since it is used in a variety of situations, the specifications may be modified.

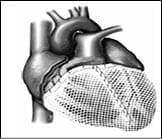

cardiac support system

Polyester, polypropylene, polyethylene, polyurethane, polytetrafluoroethylene, and other synthetic fabrics are used in artificial blood vessels. Silk fibroin is also valued for its durability and strength. Since it is used in a variety of situations, the specifications may be modified.

The Hernia patch is an effective hernia repair implant. Hernia surgery commonly employs polymer meshes. Hernia patch structures include warp knitted pillar stitch, tricot stitch, and atlas stitch. The basic structure of Marlex is tricot stitch, while Propene is atlas stitch. Pores are tiny in both. The structures have higher strength and greater stability. The materials include non-absorbable polymers like polyester, polypropylene, expanded polytetrafluoroethylene, polyvinylidene fluoride and absorbable polymers polyglycolic acid.

Artificial ligament: Artificial ligaments may be used to repair a knee joint that has been injured. Laboureau’s analysis of the Ligament Advance Reinforcement Mechanism (LARS) is commonly used in anterior cruciate ligament reconstruction. The structure is warp-knitted, and the material is medical polyester. A transverse knitted framework connects the longitudinal fibers together. The diameter of the ligament varies depending on the number of longitudinal fibers, and it is used for various circumstances.

The Cardiac Support System (CSD) is a warp-knitted elastic mesh bag that is cut and sewn to the heart’s form. The basic structure is the Atlas stitch, and the material is a multi-filamentous yarn that offers high strength and fatigue resistance while remaining flexible. The glossy fabric with warp-knitted atlas stitch is easy to slip on the surface of the heart for acute wall support.

Urethral suspension sling: The suspension sling is made of warp-knitted mesh fabric. The warp-knitted structures include tension strength, elasticity, flexibility, and a range of mesh sizes. According to research, the aperture size influences clinical outcomes. If the aperture becomes wider, so does the softness of the slings. The risk of infection will be minimized.

Knitted medical expandable metallic stent: Metallic expandable tracheal stents are used to relieve serious airway obstruction. A single strand of nitinol wire knits the Ultra flex stent (Micro-invasive, Boston Scientific, and Watertown, MA, USA). A coiled thread compresses the stent along a supple guide. The stent will self-expand to its final diameter when the thread is pulled.

Knitting structure and healthcare and hygiene products: Thermostatic textiles in surgery, medical mattresses, mattress covering material, and certain protective goods all fall under the category of healthcare and hygiene products.

Thermostatic textiles in surgery: One of the most cost-effective and interesting methods for making three-dimensional fabrics is warp-knitting. It is possible to produce many warp-knitted spacer fabrics with various patterns and characteristics. Thermostatic surgical textiles are those that can keep the patient’s body temperature steady. During the knitting process, a conductive yarn (a metal-coated polymer with a fabric characteristic, a carbon fiber, and a metal multifilament) is applied to the fabric as a single yarn at a particular yarn tension. By inserting the yarn in the center of the bars, these conductive elements are fed without deformation. As an insulator, the enclosed air in the spacer fabric prevents heat from radiating downward. Heat can be created and consumed by the human body without loss if the heating system’s side is near to the body. Thermostatic textiles can be used in several medical environments, including the prevention of hypothermia and emergency conditions such as rescuing colds.

Mattress covering material: Weft-knitted spacer fabric is knitted with two surface layers and spacer filaments connecting the two surface layers on a circular weft knitting machine with an electronic jacquard unit. The thickness ranges from 1.5 to 5.5 millimeters. Due to its good permeability, moisture absorption, elasticity, elastic controllability, and temperature regulation, weft-knitted spacer fabric is a good mattress covering material.

Conclusion

To meet the demands of medical applications, a large number of structures and materials are constantly being created. However, there are still problems with embedded devices in the human body, as some textiles have been shown to cause rejective reactions and system malfunction after long-term use. A wide variety of knitted medical textiles and materials are needed to meet certain essential requirements in medical fields, due to a rise in the ageing population, a large number of accidents, and a demand for a higher quality of life.

References

- https://www.academia.edu/13612313/Medical_Textiles

- https://www.researchgate.net/publication/321207804_Application_of_Knitting_Structure_Textiles_in_Medical_Areas

- https://onlinelibrary.wiley.com/doi/abs/10.1002/ccd.26910

Article By:

KSHIPRA GADEY – Author, Textile Value Chain