Mr. Avinash Mayekar- MD & CEO,

Suvin Advisors Pvt. Ltd.

India has made its big name after China in global market, however due to ever increasing demands from brands, continuously rising raw material prices & operating cost there is always a constant pressure for earning higher profits. India has made its good name in textile world particularly in yarn & apparel business. It is a known fact that conventional textile process is lengthy, has huge competition & hence nonwoven technologies should come to rescue Indian textile industry to create a new portfolio & fresh products basket.

Modernization has turned the tides from conventional textiles to technical textiles. Textiles are no longer just apparels used for covering & protection but have evolved into high performance delivering products. They have become part & parcel of one’s daily routine, present everywhere from the automobiles, households, buildings, hospitals, environment protection, sports, agriculture & event to the underground usage providing high comfort.

The main reason for rising demands of these highly engineered products is growing awareness of hygiene & protection, health & fitness, world class infrastructure & fascination towards leisure activities, adventure sports etc. The products like wet wipes, home textiles, travel kits, air bags, high end sports textiles and disposable products like medical textiles have today become products of daily consumption.

All these products are classic outputs of nonwoven technologies. Nonwoven technologies are compact technologies that produce complex and highly engineered products giving much higher production. As the process of these technologies is very short, the utility consumption will be much lower & further due to mass productions, the operating costs will be minimal. Moreover, the quality of product remains uncompromised as there is hardly any involvement of human beings.

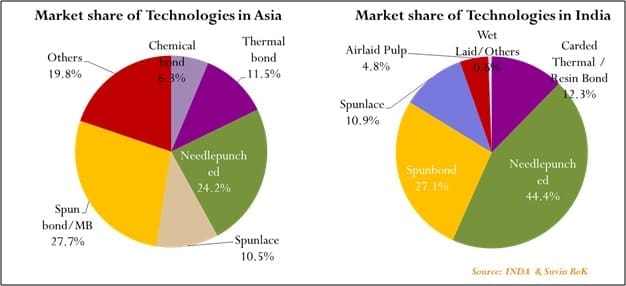

Major Nonwoven technologies are needle-punched, spunlace & spunbond. Their consumption is growing rapidly in India because of their increasing industrial as well as household applications on day to day basis. Nonwoven market is expected to reach USD 45,363 million by 2019, growing at a CAGR of 6.7% from 2013 to 2019

Needle punched Nonwovens & Applications

Needle punching is the oldest method of producing nonwoven fabric. It involves mechanically binding a web to form a fabric by penetrating the web with an array of barbed needles that carry tufts of the web’s own fibers in a vertical direction through the web. They find applications in specialized areas because of their characteristics like high water permeability, high abrasion resistance & ability to attach layers of different type of fiber webs to form composites. Needle punching is an eco-friendly technology & its estimated global share is around 12%.

The various end products developed through needle punched technology are as follows:

- Automotive: They are used in around 40 parts of automotive. Considering India’s huge automotive market which is estimated to grow with CAGR of 13%, nonwovens consumption is going to grow exponentially.

- Geotextiles: Geosynthetics is another segments where there are tremendous investments opportunities considering increasing growth in infrastructure & real estate in India as well as worldwide.

- Filtration: Nonwoven materials used in filtration applications are an important part of the worldwide nonwoven industry.

- Industrial Wipes: Industrial wipes are used for a variety of applications in industry

- Felted carpets & floor covering: Indian export of felted carpets & textile floor coverings is around $67.31 Mn in 2014 which growing at the CAGR of 31%. This steep increase is due to huge exports to Malaysia. In fact Global demand for flooring and carpets is expected to grow.

Spunlace Nonwovens & applications

Spunlace technology facilitates highest flexibility and achieves much wider product range with most compact process. Global exports of spunlace nonwoven are steady over the year and expected to reach 1.95 Bn. USD at 2% CAGR by 2017. Global production of Spunlace Nonwovens is growing at an average of 9.5%. India’s exports of Spunlace Nonwovens are increasing at a CAGR of 4%, whereas imports have increased at a CAGR of 8% in last few years. Spunlace Nonwovens are used mainly for various low weight products by using natural fibers without deteriorating their physical properties. Spunlace Nonwovens are also used in roofing substrates, consumer wipes, cotton pads, surgical disposables, etc. Growing population & growing markets of beauty & hygiene products will certainly increase demand of spunlace nonwovens in India.

Spunbond Nonwovens & Applications:

In the spunbond technology, usually a thermoplastic fiber forming polymer is extruded to form fine filaments fibers of around 15–35 micrometer diameter. The filaments are attenuated & collected on a conveyor belt in the form of a web. The filaments in web are then bonded to make spunbond nonwoven fabric. They are used for durable and disposable applications. The main applications are in automobiles, civil engineering, hygiene, medical, packaging, and agriculture.

In the spunbond technology, usually a thermoplastic fiber forming polymer is extruded to form fine filaments fibers of around 15–35 micrometer diameter. The filaments are attenuated & collected on a conveyor belt in the form of a web. The filaments in web are then bonded to make spunbond nonwoven fabric. They are used for durable and disposable applications. The main applications are in automobiles, civil engineering, hygiene, medical, packaging, and agriculture.

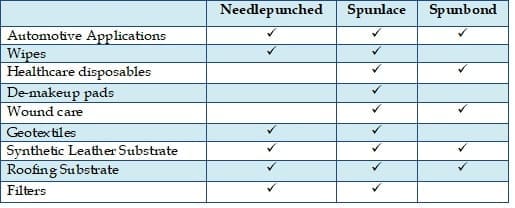

Application area & nonwoven technology matrix

Conclusion:

Despite such great demands for nonwovens, we are still stuck up with age old conventional textiles. For more than 100 years, we are catering to clothing needs of our own large population, its high time for us Indians, to think out of the box & switch over to unexploited segments like nonwovens & create a new road map for our industry. With abundant availability of raw materials from natural fibers to synthetics & highly skilled labor force at comparatively lower cost than other countries, we will surely be able to dominant this segments. However we must change our mind set & overcome our weak links in marketing of products, timely delivery of products, consistency in quality of products & after sales service to the customers. We need to adopt new strategy & improvise on above qualities to explore & reap high profits from this niche nonwoven segments.

The Entrepreneurs can further reduce their overall capital cost by importing second hand plant from European countries. Due to high labour cost in EU such plants have shut down, but they are having sound technology & viability. By bringing these plants from EU countries, the overall capital cost will be reduced by around 60%. Also as the plants are in ready conditions, less time will be required for the plant to be fully functional. This in turn will help in minimizing the pay-back period & will also be competitive with the new plants.

Thus it is important for young Indian entrepreneurs, to take calculative risk & explore the various possibilities of investing in nonwoven markets as per their strengths & weakness. They need to do complete market research on what nonwovens are, what are their properties? How they are manufactured? What their applications are & most importantly what is a market potential? A proper analysis of above will help the entrepreneurs invest in the products that best suit their capabilities.