By Tanvi Munjal

The textile industry, known for its dynamism and innovation, has long been shaped by the ever-evolving demands and preferences of consumers. One particularly interesting facet of this industry is the realm of men’s undergarments, which has undergone a remarkable transformation in recent years. From traditional staples to cutting-edge designs, the role of men’s undergarments within the textile sector has become increasingly significant, both in terms of market share and industry influence.

The Rise of Men’s Undergarments in the Textile Industry

According to a report by Grand View Research, the global men’s underwear market was valued at $30.4 billion in 2021 and is expected to grow at a compound annual growth rate (CAGR) of 7.1% from 2022 to 2030. This surge in demand can be attributed to several factors, including the growing emphasis on personal grooming, the increasing purchasing power of the male consumer, and the influence of evolving fashion trends.

Men are becoming more conscious of their appearance and are investing more in their undergarments. This shift in consumer behaviour has led to a proliferation of innovative designs, high-quality fabrics, and specialised features in the men’s undergarment market.

Types of Men’s Undergarments

Men’s undergarments encompass a variety of styles, including:

- Briefs

- Boxers

- Boxer Briefs

- Trunks

- Thongs

- Jockstraps

Each type caters to different preferences regarding comfort, support, and style. The diversity in designs is a response to changing fashion trends and consumer demands for functionality and aesthetics.

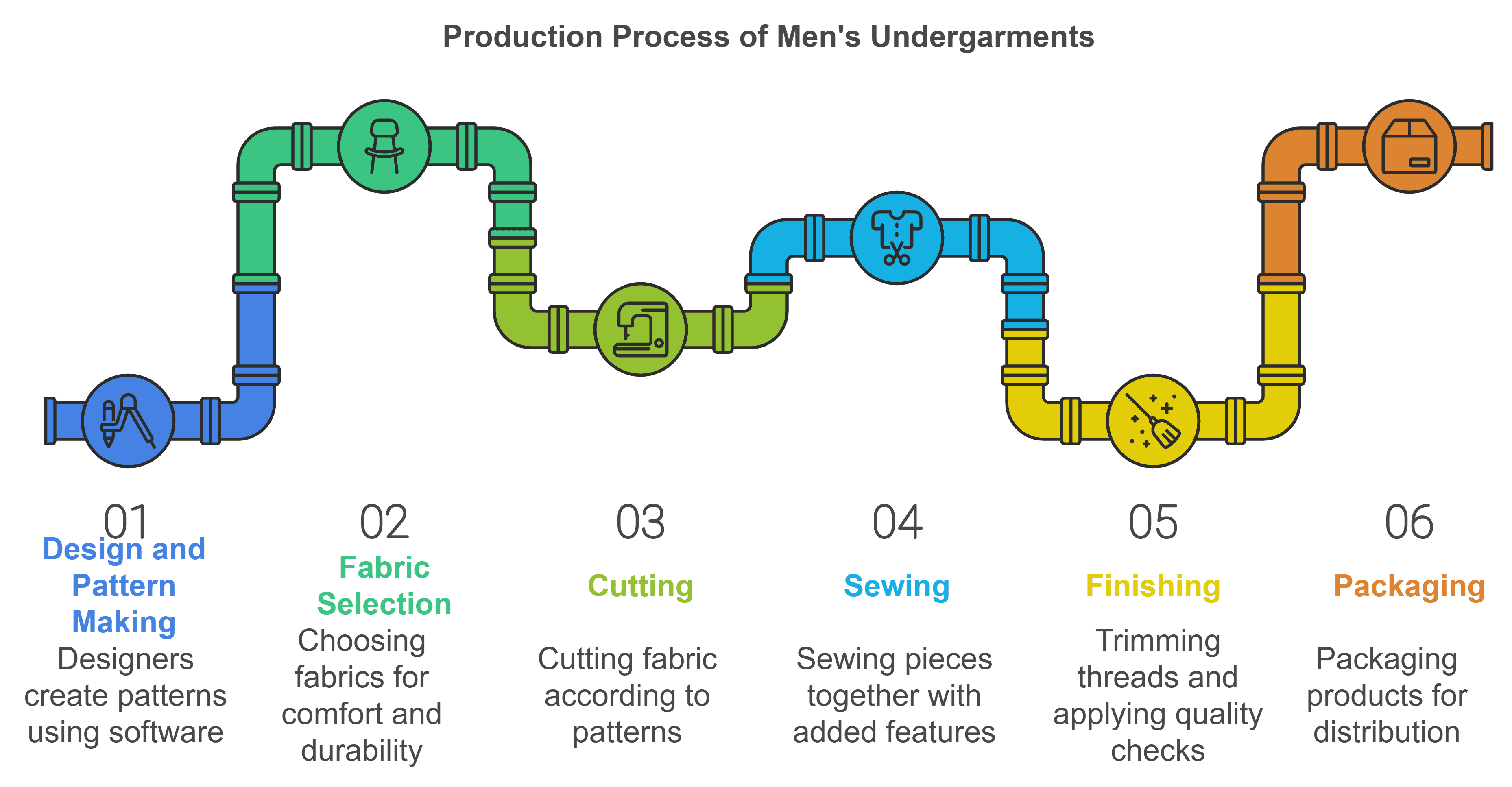

Production Process of Men’s Undergarments

1. Design and Pattern Making

Process Overview: The initial step involves designing the undergarments and creating patterns that will guide the cutting of fabric. Designers use software for pattern making, which allows for precision and efficiency.

Machines Used:

- CAD Software: Computer-Aided Design (CAD) software is utilised for creating detailed patterns.

- Plotters: These machines print the patterns onto paper or fabric for cutting.

Leading Brands: Gerber Technology, Lectra

2. Fabric Selection

Process Overview: Selecting the right fabric is crucial for comfort and durability. Common materials include cotton, modal, polyester, and blends.

Machines Used:

- Fabric Inspection Machines: These machines check for defects in the fabric before cutting.

- Roll Cutting Machines: Used to cut large rolls of fabric into manageable pieces.

Leading Brands: Saurer Group, Mayer & Cie

3. Cutting

Process Overview: After selecting the fabric, it is cut according to the patterns created earlier. This can be done manually or with automated systems.

Machines Used:

- Automatic Cutting Machines: These machines use computer-controlled blades to cut multiple layers of fabric simultaneously.

- Manual Cutting Tables: For smaller production runs, manual cutting tables are still widely used.

Leading Brands: Eastman Machine Company, Zünd Systemtechnik AG

4. Sewing

Process Overview: The cut pieces are sewn together to form the final product. This step includes adding elastic bands, labels, and any additional features.

Machines Used:

- Sewing Machines: Various types of sewing machines are used, including overlock machines for seams and cover-stitch machines for hems.

- Buttonhole Machines: For adding buttonholes where necessary.

Leading Brands: Brother Industries Ltd, Juki Corporation

5. Finishing

Process Overview: After sewing, garments undergo finishing processes such as trimming excess threads, quality checks, and adding any special finishes like anti-odour treatments.

Machines Used:

- Steam Finishing Machines: These machines help in smoothing out wrinkles and ensuring a polished look.

- Labelling Machines: For attaching care labels and brand tags.

Leading Brands: Bühler Group (for steam finishing), TEXPA GmbH & Co. KG (for labelling)

6. Packaging

Process Overview: The final step involves packaging the finished products for distribution to retailers or direct consumers.

Machines Used:

- Packaging Machines: Automated machines that wrap and label products efficiently.

- Sealing Machines: To ensure that packages are securely closed.

SWOT Analysis of Men’s Undergarments

A SWOT analysis provides insights into the strengths, weaknesses, opportunities, and threats within the men’s undergarment sector:

| Strengths | Weaknesses | Opportunities | Threats |

|

|

|

|

Men’s undergarments hold a vital position within the textile industry due to their essential role in daily wear as well as their reflection of personal style and comfort preferences. With a robust market projected for growth driven by evolving consumer demands and innovative production techniques, brands must navigate challenges while seizing opportunities presented by changing lifestyles. The future of men’s underwear appears promising as manufacturers continue to innovate in design and sustainability while addressing the diverse needs of modern consumers.