A two-step procedure separates cotton and nylon after breaking down polyester and spandex into their monomers.

The separation stage of textile recycling is omitted in a new technique, which facilitates the recovery of mixed fiber components for further use.

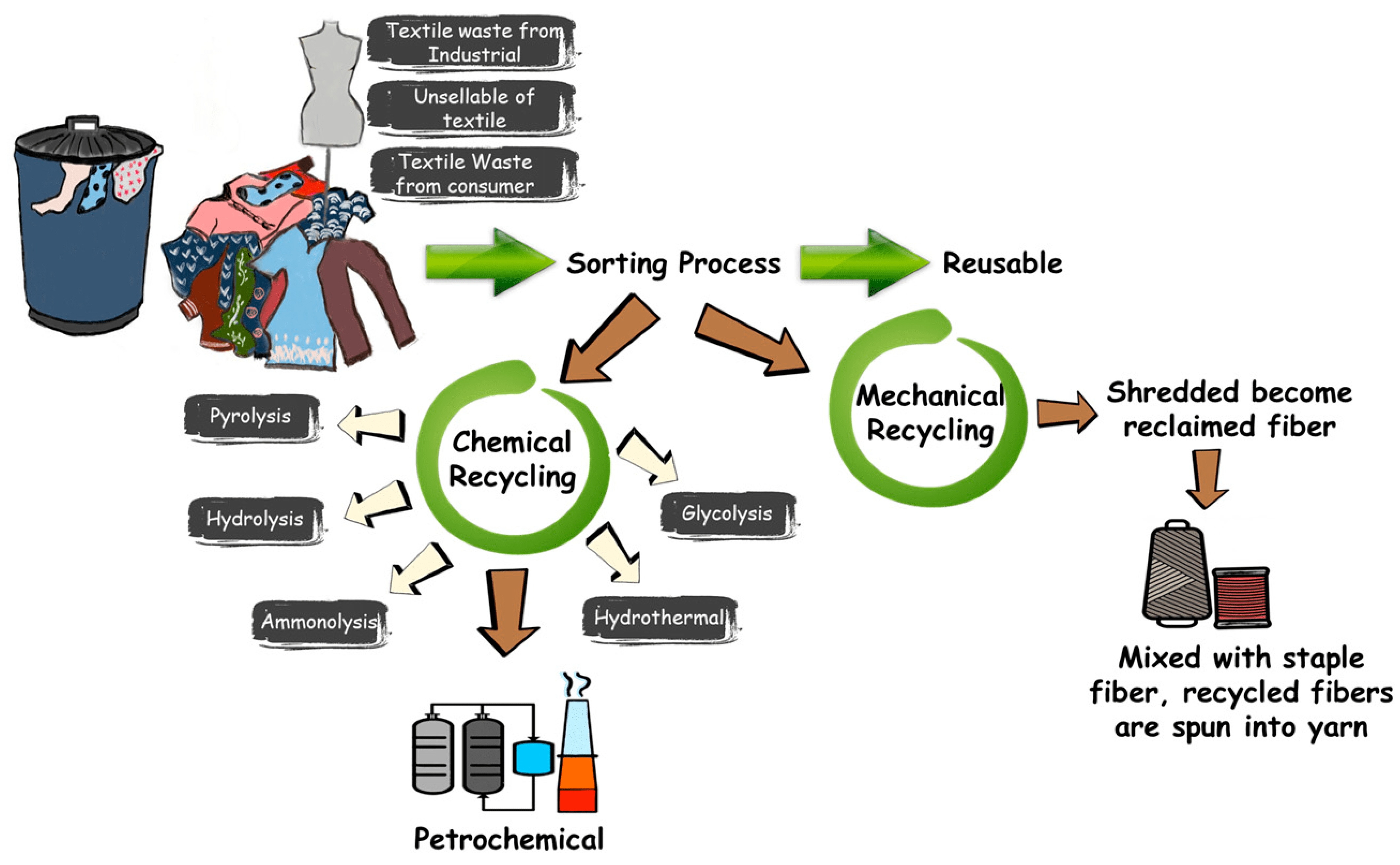

Most abandoned clothing ends up in landfills or is burned after its useful life. “At the moment, less than 1% of used clothing is recycled back into clothes,” states Erha Andini, a University of Delaware doctorate candidate in chemical engineering. The most popular recycling method rips textiles, reducing the length of their fibers to the point where the materials might not meet the strict specifications of the garment industry. Furthermore, according to Andini, sifting mixed fibers for recycling is highly costly.

A procedure developed by Andini, Sunitha Sadula, Dionisios G. Vlachos, and associates at the University of Delaware allows mixed fabrics made of cotton, polyester, spandex, and nylon to be separated. The fiber mixture is first cooked in a microwave using a zinc oxide catalyst while submerged in ethylene glycol.

This separates the spandex and polyester into their monomers, enabling the recovery of two basic components: 4,4-methylenedianiline, or MDA, from spandex and bis(2-hydroxyethyl) terephthalate, or BHET, from polyester. The leftover formic acid separates the nylon from the remaining cotton and dissolves it, allowing it to be retrieved through evaporation.