A Look at the Saree’s Product Value Chain

By Tanvi Munjal

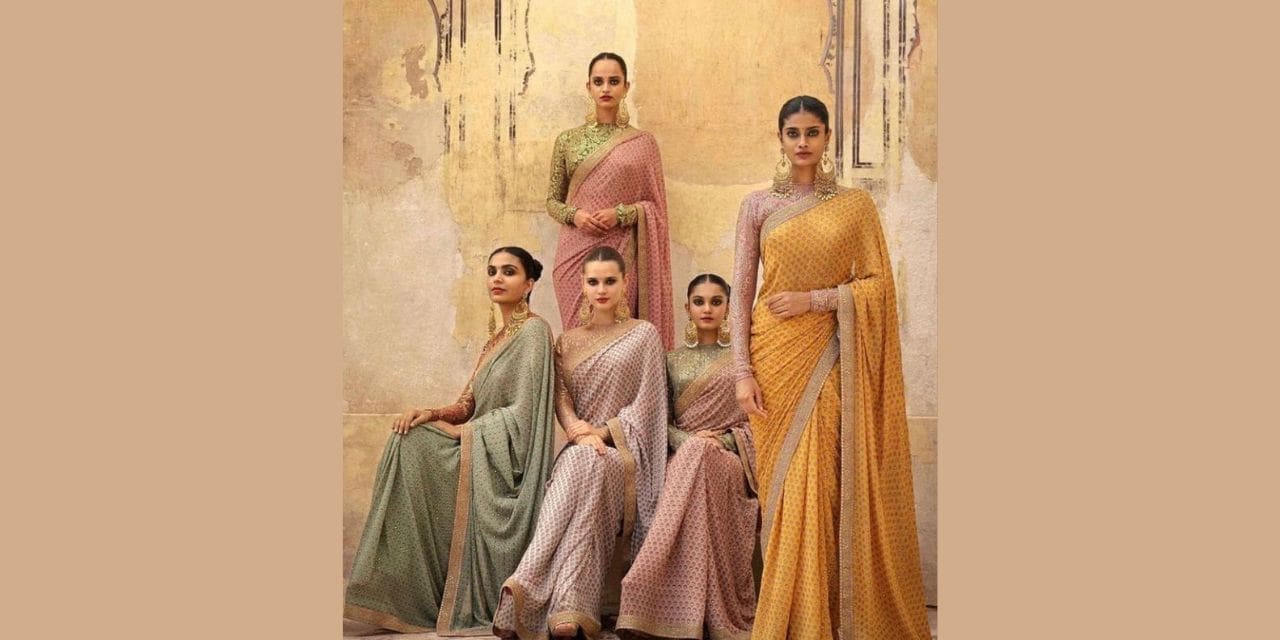

The saree, a timeless drape adorning women for millennia, embodies more than just clothing. It’s a cultural tapestry woven with tradition, artistry, and regional pride. Understanding its product value chain sheds light on the intricate journey a saree takes, from raw fibre to a cherished garment.

Origins and Evolution:

The saree’s origin remains shrouded in the mists of time, with evidence suggesting its presence in the Indus Valley Civilization (3300-1300 BCE). Over centuries, it has evolved regionally, boasting distinct weaving styles, motifs, and fabrics. From the shimmering silks of Varanasi to the intricate Kanjeevarams of Tamil Nadu, each saree whispers a unique story.

- PRODUCT CATEGORY: Clothing (Women’s Ethnic Wear)

- PRODUCT BENEFITS AND PURPOSE:

Attire: The primary purpose of a saree is to be worn as clothing. It can be dressed up or down depending on the occasion.

Cultural Expression: Sarees are deeply entwined with Indian culture and tradition. Wearing a saree allows women to connect with their heritage and express their regional identity through specific weaves, motifs, and styles.

Social Significance: Sarees play a vital role in Indian social life. They are worn for festivals, weddings, religious ceremonies, and other special occasions, signifying respect and social status.

Investment Piece: High-quality sarees, particularly handloom varieties, can be considered heirlooms, passed down through generations.

- DURATION OF PRODUCT:

Durable: Well-maintained sarees can last decades, especially those made from strong fabrics like cotton or silk.

Timeless Design: Classic saree styles never go out of fashion. They can be passed down or even adapted by future generations.

- MARKET:

Women of all ages: Sarees are appropriate for young girls to elderly women, with variations in style and formality.

Geographical Reach: Worn throughout India and by the Indian diaspora worldwide.

Socioeconomic Background: Sarees cater to a wide range of budgets, from affordable mass-produced varieties to exclusive designer pieces.

Cultural and Religious Significance: Plays a vital role in various Hindu, Jain, Sikh, and Buddhist communities.

Fashion Enthusiasts: The growing appreciation for ethnic wear and cultural expression has opened the saree market to a wider audience seeking unique and artistic garments.

Manufacturing Marvel: A Multi-Step Process

The creation of a saree involves a meticulous dance between tradition and technology. Here’s a breakdown of the key steps:

- Fiber Selection and Processing:

- Raw Materials: The journey begins with procuring fibres like cotton, silk, or synthetics. These may come from bales or skeins.

- Machines:

- Bale Openers (Trützschler): Break down compressed bales of fibre into smaller clumps.

- Carding Machines (Trützschler, Rieter): Untangle, clean, and align the fibres for spinning.

- Yarn Spinning:

- Technique: Traditional charkhas create a unique texture, while power looms offer higher production.

- Machines:

- Charkha (Traditional): Hand-operated spinning wheel.

- Ring Spinning Machines (Lakshmi Machine Works, ITG Group): High-speed machines that spin fibres into yarn.

- Dyeing and Printing:

- Colouring: Natural or synthetic dyes are used to achieve vibrant hues.

- Printing Techniques:

- Block Printing (Aarti Prints): Wooden blocks with carved designs are used to create intricate patterns.

- Digital Printing: Offers precise and detailed designs using computer-aided technology.

- Warping and Weaving:

- Warping: Lengthwise threads (warp) are prepared on warping machines to ensure consistent width and tension.

- Machine: Beam Warping Machine (Tsudakoma, Benninger)

- Weaving: The warp is stretched on a loom, and the weft threads (transverse) are interwoven to create the fabric.

- Looms:

- Power Looms (Picanol, Tsudakoma): High-speed, automated looms for mass production.

- Pit Looms (Traditional): Hand-operated looms used by skilled artisans for intricate designs and handloom weaving.

- Embellishment (Optional):

- Techniques: Zari work, embroidery, stonework, etc., add a touch of luxury.

- Process: Often done by hand, though specialised machines can replicate some embellishments.

- Finishing and Quality Check:

- Processes: The fabric is inspected for defects, washed, starched, and calendered (smoothed) for a polished finish.

- Machines:

- Washing Machines (Monforts Textilmaschinen)

- Calendering Machines (Brückner)

Popular Brands for Textile Machines:

The brands mentioned above are just a few examples. Many other companies manufacture high-quality textile machinery.

Remember: The specific machines used may vary depending on the scale of production, desired fabric quality, and traditional techniques employed.

Leading Companies Operating in the Saree Industry

| Brand Names | Since |

| Nalli Silks | 1928 |

| Manish Malhotra | 2005 |

| Ritu Kumar | 1969 |

| Satya Paul | 1985 |

| BharatSthali | 2017 |

| Fabindia | 1960 |

| Sabyasachi | 1999 |

| Kalanjali | 1992 |

| Mimosa | 1983 |

| Meena Bazaar | 1970 |

SWOT Analysis of the Saree Industry

The saree industry in India boasts a rich heritage and vibrant market. However, it also faces challenges in the modern world. Here’s a breakdown of its strengths, weaknesses, opportunities, and threats (SWOT):

Strengths:

- Rich Heritage and Cultural Significance: The saree’s timeless appeal is deeply rooted in Indian culture and tradition, ensuring a steady demand.

- Skilled Artisanship: India is home to a wealth of talented weavers who preserve traditional handloom techniques, creating unique and high-quality sarees.

- Diverse Range of Styles and Fabrics: From classic weaves to contemporary designs, the saree caters to various tastes and budgets, offering a wide variety for consumers.

- Government Support: Initiatives like “Make in India” promote the revival of handloom weaving and provide financial assistance to weavers.

Weaknesses:

- Competition from Power Looms and Machine-made Imitations: These threaten the livelihood of handloom weavers and often compromise on quality. This can lead to a decline in the value perception of sarees.

- Limited Marketing and Branding: The industry struggles to reach a wider audience, especially younger generations, who may find traditional marketing techniques less appealing.

- Fluctuations in Raw Material Prices: Cotton and silk price variations can significantly impact production costs and profit margins for saree manufacturers.

- Lack of Standardisation: Variations in quality and pricing across different regions and vendors can be confusing for consumers.

Opportunities:

- Growing E-commerce Market: Online platforms provide a wider market reach for weavers and designers, enabling them to connect with a global audience.

- Fusion Design and Innovation: Incorporating contemporary elements into traditional designs can attract younger customers seeking a unique blend of heritage and modernity.

- Sustainability Focus: Promoting eco-friendly practices and using organic materials can appeal to environmentally conscious consumers.

- Government Skill Development Programs: Initiatives to train and upskill weavers can ensure the preservation of traditional techniques and improve product quality.

Threats:

- Westernization and Changing Fashion Trends: The growing influence of western wear can lead to a decline in the popularity of sarees, especially among younger generations.

- Cheap Imports: The influx of low-quality, mass-produced sarees from other countries can put pressure on domestic saree prices.

- Economic Downturns: Reduced consumer spending during economic recessions can negatively impact saree sales.