Mayur Basuk* & Amit Sengupta, Scientist

Wool Research Association, Thane, Maharashtra, India

Abstract

Technical textiles are divided into 12 segments & Sportech is one of them. Artificial Turf, a Sports accessories/functional Sportech product comes under the Sportech segment. In India, Sportech is growing rapidly & becoming popular. Artificial turf is a surfacing material used to imitate grass. It is generally used in areas where grass cannot grow, or in areas where grass maintenance is impossible or undesired. Artificial turf is used mainly in sports stadiums and arenas, but can also be found on playgrounds and in other spaces. The present article deals with the history of artificial turf and various aspects like features, components, manufacturing process, future trends & demand, scenario of artificial turf usage in India etc.

Keywords: Artificial Turf, Components, Manufacturing process, Advantages & Disadvantages, Market scenario, Future trends.

- Introduction:

Artificial turf or synthetic turf is a man-made surface manufactured from synthetic materials with appearance similar to natural grass. It is used for making world-class surfaces for playing sports (Hockey, Soccer, Baseball, Tennis, Ski and snowboard) which are normally played on grass [1]. The hockey stadiums account for most of the consumption of the artificial turf in India. It is also used in indoors or outdoors for landscaping: Rooftops, Balconies, Atriums, Home and Corporate Lawns, Hotels and Resorts, Club Houses, Airports, Jogging / Walking Tracks, Shopping Malls, Traffic Islands, Road Medians & Kid’s play area etc.

Synthetic grass was first introduced in the 1960s for professional sports teams, and is now widely used in all levels of sports for indoor and outdoor fields. Artificial turf is considered a safe alternative to natural grass; an arid environment or one where there is little natural light are examples, turf has no direct harmful effects to pets or children. The advantages of artificial turf are that it doesn’t need water, fertilizer or mowing. It holds up to wear and tear far better than natural grass. Artificial turf can withstand significantly more use than natural grass and can therefore be used much more frequently. This allows sports ground owners to generate more income from their facilities. Turf generally lasts at least a decade. Many are dog durable and gopher proof (there are no roots to eat). It’s safe for children and pets with regards to not twisting ankles in gopher holes. It’s easy to clean with a hose and doesn’t attract bugs and pests. It can’t get grass stains and it won’t have bare or brown spots. Some artificial turf systems allow for the integration of fiber-optic fibers into the turf. This would allow for lighting or advertisements to be directly embedded in a playing surface, or runway lighting to be embedded in artificial landing surfaces for aircraft [2, 3].

However, artificial turf does have few disadvantages. It tends to get hotter than natural grass in the mid-day sun and materials on the surface don’t break down as easily. The production and transportation of artificial turf releases more greenhouse gases than the maintenance of natural turf. It will need to get replaced and disposed of in a landfill since most types cannot be recycled. Despite the advances in technology, less expensive types of artificial turf and infill still may not have as much give as grass. Several studies have shown that the artificial turfs have a higher injury rate than grass on play grounds. The new manufacturing and installation procedures have resulted in lowering of injury rates than on natural grass. Although it is still more costly than natural turf in the short term, the cost has come down as technologies have improved, making artificial turf a realistic option for homeowners today [4, 5].

Background History

Artificial turf has been manufactured since the early 1960s, and was originally produced by Chemstrand Company (later renamed Monsanto Textiles Company). It is produced using manufacturing processes similar to those used in the carpet industry. Since the 1960s, the product has been improved through new designs and better materials. The newest synthetic turf products have been chemically treated to be resistant to ultraviolet rays, and the materials have been improved to be more wear-resistant, less abrasive, and, for some applications, more similar to natural grass.

In the early 1950s, the tufting process was invented. A large number of needles insert filaments of fiber into a fabric backing.

Then a flexible adhesive like polyurethane or polyvinyl chloride is used to bind the fibers to the backing. This is the procedure used for the majority of residential and commercial carpets. A tufting machine can produce a length of carpet that is 15 ft (4.6 m) wide and more than 3 ft (1 m) long in one minute. In the early 1960s, the Ford Foundation, as part of its mission to advance human achievement, asked science and industry to develop synthetic playing surfaces for urban spaces. They hoped to give urban children year-round play areas with better play quality and more uses than the traditional concrete, asphalt, and compacted soil of small urban playgrounds. In 1964, the first installation of the new playing surface called Chem grass was installed at Moses Brown School in Providence, Rhode Island.

In 1966, artificial turf was first used in professional major-league sports and gained its most famous brand name when the Astrodome was opened in Houston, Texas. By the first game of the 1966 season, artificial turf was installed, and the brand name Chem grass was changed to Astro Turf.

Artificial turf also found its way into the applications for which it was originally conceived, and artificial turf was installed at many inner-city playgrounds. Some schools and recreation centers took advantage of artificial turfs properties to convert building roofs into “grassy” play areas.

After the success of the Astrodome installation, the artificial turf market expanded with other manufacturers entering the field, most notably the 3M (Minnesota Mining and Manufacturing) Company with its version known as Tartan Turf. The widespread acceptance of artificial turf also led to the boom in closed and domed stadium construction around the world.

In the early 1970s, artificial turf came under scrutiny due to safety and quality concerns. Some installations, often those done by the number of companies that sprang up to cash in on the trend, began to deteriorate. The turf would wear too quickly, seams would come apart, and the top layer would soon degrade from exposure to sunlight. Athletes and team doctors began to complain about the artificial surfaces, and blamed the turf for friction burns and blisters. Natural turf yields to the force of a blow, but an arm or leg driven along the unyielding surface of artificial turf is more likely to be injured. Since artificial turf does not have the same cooling effects as natural turf, surface temperatures can be 30° warmer above the artificial surfaces. Baseball players claimed that a ball would bounce harder and in less predictable ways, and some soccer players claimed that the artificial surface makes the ball roll faster, directly affecting the game. However, the National Football League and the Stanford Research Institute declared in 1974 that artificial turf was not a health hazard to professional football players, and its use continued to spread.

In the 1990s, biological turf began to make a comeback when a marketing of nostalgia in professional sport resulted in the re-emergence of outdoor stadiums. Many universities—responding to the nostalgia, advances in grass biology, and the fears about increased risk of injury on artificial turf—began to reinstall natural turf systems. However, natural turf systems continue to require sunlight and maintenance (mowing, watering, fertilizing, aerating), and the surface may deteriorate in heavy rain. Artificial turf offers a surface that is nearly maintenance-free, does not require sunlight, and has a drainage system. Recent developments in the artificial turf industry are new systems that have simulated blades of grass supported by an infill material so the “grass” does not compact. The resulting product is closer to the look and feel of grass than the older, rug-like systems. Because of these factors, artificial turf will probably continue to be a turf surface option for communities, schools, and professional sports teams.

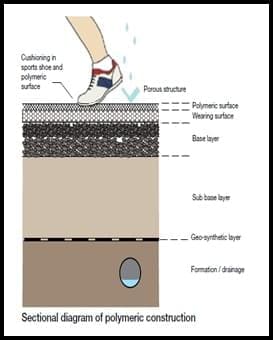

- Components of Artificial Turf:

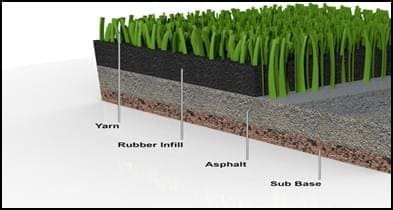

Basic components of artificial turf are as follows:

- Pile Fibre – The grass like piles are non-abrasive and soft to touch. It is made of either PP/PE or nylon/nylon 6.6, which is custom extruded into a monofilament ribbon form. The pile fibre has to allow for smooth ball roll and bounce, support non-directional foot traction, allow for water permeability and should have the correct balance of strength, elasticity and stiffness to withstand the wear and tear of regular usage.

- Backing Fabric – The material to which surface fibres are attached to form the underside of the artificial turf surface. The backing has to permit water to flow through the fabric readily.

- Shock-Absorbing Foam – It provides cushioning for running or falling athletes. The foam is made of a closed-cell polymer alloy like polyurethane, typically 1/2 inch in height and perforated for vertical drainage.

- Supporting Base – It supports the load placed on the entire structure, typically a 2-feet or 3- feet layer of asphalt or concrete Installation and maintenance are very crucial for the performance of Artificial Turf. For ground installations, a good quality sub-base is very important.

Fig 1: Components of Artificial Turf

The pile fibres are knitted directly into the backing using flat-bed Raschel knitting machines which are between 4.5 m to 5 m wide to form a mechanically strong and stable structure. The sewing threads which are used are high-strength, weather resistant and pigmented to exactly match the colour of the turf.

- Raw Materials:

The quality of the raw materials is crucial to the performance of turf systems. Almost anything used as a carpet backing has been used for the backing material, from jute to plastic to polyester. High quality artificial turf uses polyester tire cord for the backing.

The fibers that make up the blades of “grass” are made of nylon or polypropylene and can be manufactured in different ways. The nylon blades can be produced in thin sheets that are cut into strips or extruded through molds to produce fibers with a round or oval cross-section. The extruded product results in blades that feel and act more like biological grass. Cushioning systems are made from rubber compounds or from polyester foam. Rubber tires are sometimes used in the composition of the rubber base, and some of the materials used in backing can come from plastic or rubber recycling programs. The thread used to sew the pads together and also the top fabric panels has to meet the same criteria of strength, color retention, and durability as the rest of the system. Care and experience must also be applied to the selection of the adhesives used to bond all the components together.

. Types of artificial grass:

- Type according to infill content:

(i) Unfilled: Unfilled pitches were the first type of system implemented for sport. They had short pile height, were dense in quantity and had no infill material. They were often made of nylon, which meant the prototypes were often tough and abrasive. Partly due to the abrasiveness, watered unfilled fields were developed and have since been popular for elite levels of hockey. The water is applied through an irrigation system to the surface immediately before play, and it reduces the player-to-surface friction, modifies the speed of the hockey ball and cools the surface in hot weather. It can require a lot of water to maintain the playing characteristics, during a match or training session. Due to the cost of the high-density unfilled carpet, required irrigation systems, and water, unfilled carpet technology is now focused on producing non-watered unfilled carpet that can replicate the playing characteristics of watered fields. The key change is from abrasive nylon fibre to softer polyethylene yarn. Several such polyethylene-based installations are being trailed in Australia.

(ii) Dressed: Dressed systems are a derivative of the sand-filled system, and intermediate in properties and playing characteristics between the traditional filled and unfilled carpets. They can have either a shorter, denser pile than the standard filled system (with a reduced quantity of sand fill of about 60% of the fibre height) which is considered suitable for hockey, soccer (training), touch rugby, lacrosse and cricket (fielding practice). the longer pile (35-65mm) used for soccer, rugby, Australian rules football and cricket, which is dressed with sand, rubber granules or both to within about 15-20mm of the top of the fibre.

(iii) Filled: With filled artificial grass systems, the artificial grass fibres or blades are fully supported or stabilized by the addition of a filling material, such as sand, clay & rubber granules, or a mix of sand and rubber granules. These carpets are marginally less expensive than non-filled systems because the pile density can be reduced due to the sand fill, which is normally taken to within 5-6mm of the fibre tips. The sand and fibres combine to form the characteristics of the playing surface. Artificial grass surfaces that are filled with sand only are generally suitable for hockey, tennis, lawn bowls, touch rugby, lacrosse, and soccer (training) and multifunction use. See Section 1.6 for more details on sport specific requirements.

- Types according to pile height:

- Short-pile turf

(i) Unfilled: High-density of fibres and used predominantly for cricket pitches (either 8, 10 or 12mm in pile height, or for elite level hockey pitches generally 10-12mm). The unfilled hockey pitches have, until now, had to be kept wet to improve foot traction, ball speed and heat suppression, but suppliers are now responding to the call from the International Hockey Federation to develop a dry unfilled carpet that can perform to elite level standard.

(ii) Dressed: Nominally 10-13mm high with medium-pile density, sand-dressed carpets are a hybrid development midway between sand-filled and elite unfilled pitches. Becoming popular in Australia for hockey, dressed carpets (sand filled to approximately 60% of the pile height) are also suitable for lacrosse, and for training for soccer, Australian rules football, touch rugby and cricket (fielding practice).

- Medium-pile turf

(i) Filled: These carpets are in the range of 20- 35mm and have traditionally been the hard-wearing sand-filled carpets used for hockey, tennis, lawn bowls and for training level activities for a variety of other sports.

(ii) Dressed: An interesting and recent development is the approval of soccer pitches in Europe that have sand infill and a shock pad instead of rubber granule infill and no shock pad. Because of the lack of rubber granule infill, the pile height can be lower than the typical third generation dressed pitch. This product may be similar to the new Australian Football League (AFL) and Cricket Australia-approved artificial grass surface, and might be the first example of a hybrid design that is close to meeting both AFL and Federation Internationale de Football Association (FIFA) specifications.

- Long-pile turf

(i) Dressed: Long-pile turf has long blades of fibre similar in height to some natural turf playing surfaces. The long fibres (40- 65mm in length) provide cushioning and allow for a great amount of infill to be integrated into the pitch adding to the shock absorbency and force reduction characteristics of the ground, and plays more like grass. These fibres can be monofilament (single fibre) or multi-ended filament yarns (brush-like at the tip), and are proving to be popular for soccer, rugby, Australian rules football/cricket and golf. The pitch infill is comprised of a sand layer at the base with, typically, (recycled) rubber granules above the sand layer. The total infill height is generally between one half and two thirds of the pile height. Some sports (eg. rugby) may also need to have a shock pad under the ‘turf’. The shortest of the long-pile turfs (35 – 40 mm) are targeted at Australian rules football and cricket (outfield) usage, and provide an ‘acceptable’ surface for some competitive soccer and hockey (lower levels of competition and school usage). A 55 – 65 mm pile height is the recommended soccer turf height, whilst rugby recommends 65 mm, often with a shock pad as well. Refer Appendix 8 for summary table. The latest development with long pile turf is the development of even longer fibre carpet (80-85mm, with approximately 60mm of infill material). This is being hailed as the first suitable artificial grass system for athletics field events including hammer, shot put, discus and javelin [6].

- The Manufacturing Process:

Artificial grass carpet is generally produced in one of two ways:

(i) Tufting is the most common type of manufacture where the fibre is tufted into a primary backing cloth, normally made from woven polypropylene or urethane, and the individual tufts are anchored by the application of a latex based secondary backing material. These backing layers also contribute to the dimensional and structural stability of the carpet.

(ii) Needle-punching is where the fibre in the pile forms both the pile structure and the majority of the backing cloth. The fibres are needled into a flat primary cloth, then secondary needled to pull through and angle the fibre to a felt like structure of the desired quality and configuration of pile. Artificial grass can also be produced through knitting and weaving methods (used for some bowls carpets), but is rarely used because of its greater expense [6].

The ‘grass’ part of a turf system is made with the same tufting techniques used in the manufacture of carpets. Generally extruding, knitting, stitch bonding, coating and tufting technologies are involved in artificial turf making.

- The first step is to blend the proprietary ingredients together in a hopper. Dyes and chemicals are added to give the turf its traditional green color and to protect it from the ultraviolet rays from the sun.

- After the batch has been thoroughly blended, it is fed into a large steel mixer. The batch is automatically mixed until it has a thick, taffy-like consistency.

- The thickened liquid is then fed into an extruder, and exits in a long, thin strand of material.

- The strands are placed on a carding machine and spun into a loose rope. The loose ropes are pulled, straightened, and woven into yarn. The nylon yarn is then wound onto large spools.

- The yarn is then heated to set the twisted shaped.

- Next, the yarn is taken to a tufting machine. The yarn is put on a bar with skewers (a reel) behind the tufting machine. It is then fed through a tube leading to the tufting needle. The needle pierces the primary backing of the turf and pushes the yarn into the loop. A looper, or flat hook, seizes and release the loop of nylon while the needle pulls back up; the backing is shifted forward and the needle once more pierces the backing further on. This process is carried out by several hundred needles, and several hundred rows of stitches are carried out per minute. The nylon yarn is now a carpet of artificial turf.

- The artificial turf carpet is now rolled under a dispenser that spreads a coating of latex onto the underside of the turf. At the same time, a strong secondary backing is also coated with latex. Both of these are then rolled onto a marriage roller, which forms them into a sandwich and seals them together.

- The artificial turf is then placed under heat lamps to cure the latex.

- The turf is fed through a machine that clips off any tufts that rise above its uniform surface.

- Then the turf is rolled into large v/lengths and packaged. The rolls are then shipped to the wholesaler.

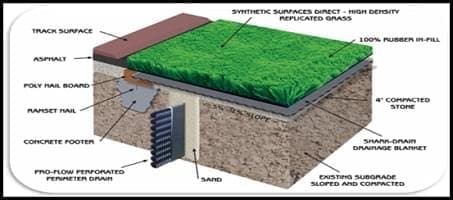

- Installation:

Artificial turf installation and maintenance is as important as its construction.

- The base of the installation, which is either concrete or compacted soil, must be leveled by a bulldozer and then smoothed by a steam roller. Uneven surfaces will still be evident once the turf is supplied.

- For outdoor applications, intricate drainage systems must be installed, since the underlying surface can absorb little, if any, rainwater.

- Turf systems can be either filled or unfilled. A filled system is designed so that once it is installed; a material such as crumbled cork, rubber pellets, or sand (or a mixture) is spread over the turf and raked down in between the fibers. The material helps support the blades of fiber, and also provides a surface with some give, that feels more like the soil under a natural grass surface. Filled systems have some limitations, however. Filling material like cork may break down or the filling material can become contaminated with dirt and become compacted. In either case the blades are no longer supported. Maintenance may require removing and replacing all of the fill.

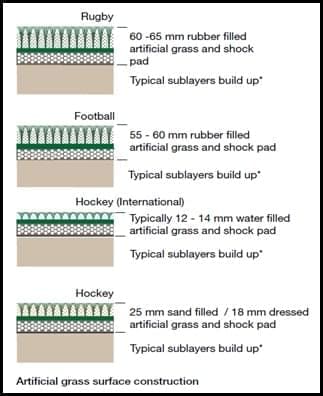

Fig. 2 Different requirement of grass properties for different sports

Proper installation is vital for guarantee a long lifespan for artificial turf. Proper drainage is needed before the turf installation. A layer of good draining collection should be laid down and compressed below the turf for safe installation. The turf is roll out, super glued with special bonding agent at line of ground with long steel shafts. Expert installation is suggested for long-lasting constancy supplier that exactly prepares a site may have more fee – but the additional price is sound value it. Special type of sand is also used bnot give as much of a soften feel underneath your foot. The infill helps grip down the turf and stops creases as well as provides a light barricade to make sure a longer life in support of the backing. Infill is worth the funds if someone’s home turf gets a bunch of use, chiefly from children playing. However, it is not value the expenditure if the artificial grass is just for demonstration. There is a considerable straight deal required with artificial turf. Conversely, greater than the life of an artificial lawn, the cost can be recouped from side to side repairs savings. Normally artificial turf lasts more than 20 years with suitable maintenance and potentially up to 30 years. So many dealers offer warranties of 8 years or more. The majority varieties of turf have a covering to guard against UV rays and put a stop to fading. Blustery weather is not bean anxious since the turf is secured to the ground. During midday straight sun, the grass may feel warm to the feel. Certain infill may decrease heat absorption [7].

Fig 3: Installation of Artificial Turf

- Quality Control

The standards for artificial turf used in football grounds are governed by FIFA. It specifies various ball / surface and player / surface tests for these turfs and certifies as FIFA recommended 1 Star and 2 Star. 1 Star is mainly for recreational, community and municipal use while 2 Star for artificial turf designed specifically for the playing characteristics of professional football. Both the FIFA recommended 1 Star and 2 Star have to go through a series of stringent laboratory and field tests for getting the FIFA certificate. The International Hockey Federation (FIH) has developed standards for Hockey turfs. These products are tested and verified by a FIH accredited laboratory. Because of the high use of artificial turf and the constant scrutiny by professional athletes, new products must undergo a number of tests as they are being developed. In 1994, the American Society for Testing and Materials (ASTM) published a list of standard methods for the testing of synthetic turf systems. It contains over two dozen tests for the properties of turf systems.

As part of ASTM’s testing, the backing fabric is tested for strength. The force it takes to separate the individual tufts or blades is also measured. In tufted turf, this test usually measures the strength of the adhesive involved. To test how resistant the turf is to abrasion, the ASTM recommends testing the fabric by running it under an abrasive head made of spring steel, while another ASTM test measures how abrasive the turf will be to the players. The ASTM also has tests that measure the shock absorbency of the turf system, and there are also tests to see how well the turf stands up during the course of a game or even prolonged tournament play.

Several quality checks are performed during the manufacturing process, as well. For example, according to AstroTurf Incorporated, the following quality checks are performed: 19 checks for the raw materials, eight checks for extrusion, six checks for unfinished fabric, and 14 checks for finished fabric.

As per FIFA, Laboratory test requirements are as follows:

- Vertical ball rebound

- Angle ball rebound

- Ball roll

- Shock Absorption

- Vertical Deformation

- Rotational Resistance

- Linear Friction – Stud ,Deceleration Value

- Linear Friction – Stud ,Slide Value

- Skin / surface friction

- Skin abrasion

- Surfaces for Outdoor Sports Areas – Exposure of Synthetic Turf to Simulated Wear (EN 15306)

- Artificial Weathering

- Artificial turf – Colour change

- Pile yarn (s) – Tensile strength

- Polymeric infill -Colour change

- Joint strength – after immersion in hot water

- Joint strength: stitched seams

- Joint strength – unaged

- Joint strength – after immersion in hot water

- Joint strength: Bonded seams

- Joint strength – unaged

- Tuft withdrawal

- Tensile strength of shockpads and e-layers (if supplied as part of system)

- Water permeability

- Stabilising infill

- Byproducts/Waste

Defected artificial turf batches are discarded as are nylon yarn that is damaged. Completed turf is generally recycled, but not reused as artificial turf. The earth that is cleared from the installation site is transported to a landfill and discarded. Older turf that has been worn down is typically recycled.

The arguments about the environmental impact of artificial versus biological turf continue. Both create large amount of water run-off, adding to sewage problems. Chemical processes are used in the manufacture of raw materials for artificial turf, but most biological grass in stadium applications requires chemicals in the form of fertilizer and pesticides for maintenance.

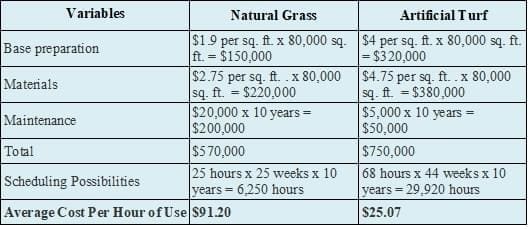

- Cost analysis of synthetic grass Vs natural grass

Approximate cost analysis of synthetic grass Vs natural grass (Figures based on 80,000 square foot fields and average costs and usage rates across North America) are given below:

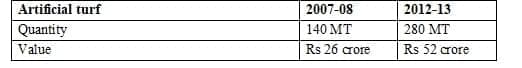

- Indian Market Scenario of Artificial Turf

There are no manufacturers of artificial turf in India. The demand is met entirely through imports. Artificial turfs are imported under the HS code 570330.

The major importers of Astro-turf (fabrics) are Inderjit Mehta Construction Pvt. Ltd (representing Polytan Sportstattenbau GmbH), Suravaram Marketing Pvt. Ltd (Licensee of Field Turf – Tarkett in India).

The hockey stadiums account for most of the consumption of artificial turf in India. It also use in indoor or outdoor landscaping. The key market driver is the government expenditure to improve the hockey infrastructure. The Commonwealth games and Hockey Olympics, which are hosted in India, are expected to increase the short-term demand of astro-turfs in India. In the long term, various Government schemes providing subsidy to universities / colleges for lying down of artificial turfs augur well for this industry. Other than sports, the usage of artificial turf for landscaping is increasing on account of increasing awareness and acceptance of the product and also because of the rising labour costs in maintaining natural grass lawns.

More than 1000 installations of astro-turf are already complete in India [8]. There are 20 artificial turf hockey pitches in all over India. The Ministry of Youth Affairs & Sports has approved laying of 12 new astroturfs at the cost of Rs. 42 crore with a view to create better facilities for hockey in the country. Locations for new astroturfs include one at Singpura (Baramullah, J&K) and tribal pockets like Rajnandgaon (Chhattisgarh), Hazaribagh (Jharkhand) and Kokrajhar (Assam). At another eight places, the work for establishment of Astroturf is at different stages of the completion. Besides this, the work relating to replacement of old astroturfs at NIS, Patiala and Kolkata is underway. The proposal for setting up of another four astroturfs is in the pipeline. By the end of 2009, India had 30 astroturfs spread across the country for the promotion of hockey. Hence, on an average, 6-8 astro-turfs are being laid every year In India. In addition, 3-4 synthetic athletic tracks are being laid in India every year. The cost of laying an artificial turf for a hockey field is approximately Rs 3.5 crore which usually lasts for a minimum of ten years assuming proper maintenance. The cost of an 8-lane synthetic athletics track is around Rs 2.5 crore. Technical textiles account for 60% of the cost. The demand for artificial turfs / synthetic tracks is likely to double in the next 5 years as a result of strong government focus on developing the sports infrastructure of India. The Indian artificial turf market size is expected to increase to around 280 MT by 2012-13. Hence, in value terms, the market size of the artificial turfs market in India is expected to increase to around Rs.52 crore by 2012-13 [9].

The market size has been increased by 20% to account for usage in landscaping. The demand for artificial turfs / synthetic tracks is likely to double in the next 5 years as a result of strong government focus on developing the sports infrastructure of India.

The Indian artificial turf market size is expected to increase from 140 MT in 2007-08 to around 280 MT by 2012-13.

No inflationary increase has been assumed for the price of artificial turfs. Hence, in value terms, the market size of the artificial turfs market in India is expected to increase from Rs 26 crore in 2007-08 to around 52 crore by 2012-13. [10]

The current and future forecast of artificial turf consumption is given below:-

- Concluding remarks & Future Trends

The use of artificial turf for sport surfaces has seen an enormous increase in recent years. The reasons for this are various and artificial turf is increasingly being used for soccer applications, especially with the development of the so-called `third-generation’ artificial turf consisting of artificial fibres tufted on a backing with an infill of sand and rubber granules. Many good results have already been obtained with fibres of the right geometry, a good behavior in resilience and resistance to fibrillation. The temperature profile during sliding is very important for the comfort of the player and avoiding burn wounds in combination with other characteristics of the artificial turf, such as shock absorption, energy restitution and quality of the yarns.

For the future, a better insight will be obtained in the relationship between the fiber structure and resilience and resistance to fibrillation. This will lead to possible developments of polymers with better properties, may be used in multilayered artificial grass blades, and much better control of the processing of these polymers.

The future generation of artificial turf fields will be based on two types of fibers, one that is standing upwards and another that will be constructed of crimped fibers without infill of rubber particles. This will increase the demand for playing on artificial turf fields [9, 10].

The engineering and design of both artificial and biological turf systems are constantly improving. As new stadiums are built, the owners and architects strive to give a more old-fashioned feel to the structures, which usually means no dome or a dome that allows the use of biological turf.

Recent installations of artificial turf have included new advancements that serve both economic and environmental needs. Large holding tanks are built beneath outdoor installations. The water that runs off the surface is held in the tanks, and used later for watering practice fields or nearby lawns.

Another recent development has been a hybrid of filled turf and biological grass. Once artificial turf is installed, it is filled not with rubber or sand, but with soil. Grass seed is then planted in the soil, nurtured and grown to a height above that of the artificial turf. The resulting combination combines the feel, look, and comfort of biological turf with the resilience and resistance to tearing and divots of artificial turf. Of course, it also requires all the maintenance of both systems, and it is not suitable for most indoor applications.

One should stay side by side of developments regarding ultimate recycling of artificial turf fields as currently installed products come to the end of their useful life. If manufacturers begin to recycle their fields, he should investigate to be certain these claims can be confirmed and, if so, end of life field management could become a vital choice stand3. It would still be meaningful to have assess and compare potential impacts resulting from particular maintenance actions, such as pesticide use, gasoline consumption, etc. Even without a full cost comparison, it might be possible to identify ways to reduce the impacts field maintenance for both natural turf and artificial turf fields.

Artificial turf is an imported product and there is no manufacturer available till now in India. So there are ample of opportunities for Indian entrepreneurs to enter in this field. It might be possible to identify ways to reduce the impacts of field maintenance for both natural turf and artificial turf fields even without a full cost comparison. Further, much research is required on the subject for developing the innovative products and design.

Acknowledgement: The authors are grateful to Director and Dy. Director, Wool Research Association, Thane, Maharashtra, India for giving valuable inputs, guidance and support.

References:

- Source: Baseline survey of the technical textile industry in India, ICRA Management Consulting Services Limited, March 2009

- Source: Technology mission on technical textiles compendium on centers of excellence, Ministry of Textiles, Govt. of India, 2011

- Source: https://technotex.gov.in

- Source: https://en.wikipedia.org

- Source: https://www.watersavingtips.org/at.pdf

- Source: A Report on Artificial Grass For Sport, Department of planning & community development of State Govt. Victoria

- Source: www.technical textile.net

- Source: www.fieldturfindia.com

- Source: https://www.ficci-progressivemaharashtra.com

- Goswami K.K, Advances in Carpet Manufacture; Woodhead publishing limited 2009, Developments in textile sports surfaces; G Schoukens, Ghent University, Belgium, pp 102 -137

- Source: www.technicaltextile.net