An award, more extensive certifications and an “explanatory” image for the range of new generation of chemical auxiliaries

What’s new for REVECOL® by ERCA Textile Chemical Solutions? After the inspiring and productive meetings last June at ITMA where synergies with Patagonia® and YKK were announced, REVECOL® resumes its dialogue with professionals from the textile world, keeping its promise not only to “share” this responsible innovation with stakeholders, customers and the general public, but above all to illustrate its evolution and ongoing development. We are talking about a company and a range of products capable of “transforming problems into solutions” with the aim of bringing a new culture of sustainability and circularity within textile production, and inevitably leading to innovations that follow one another at an incessant pace.

Thanks to a 100% Made in Italy, highly technological, pioneering and end-to-end certified production process, REVECOL® transforms critical waste materials (in this case, used vegetable oils) into a complete range of innovative and responsible chemical auxiliaries designed for the entire textile industry and its various applications.

Conveying the values of the new generation REVECOL® chemicals to the public – from customers within the textile production chain to final consumers – is not an easy task, even more so if we then add the “many” unique characteristics defining REVECOL® such as circularity, safety, high performance, competitiveness and its ability to be used on any type of textile fibre, both virgin and recycled…we are clearly facing a challenge.

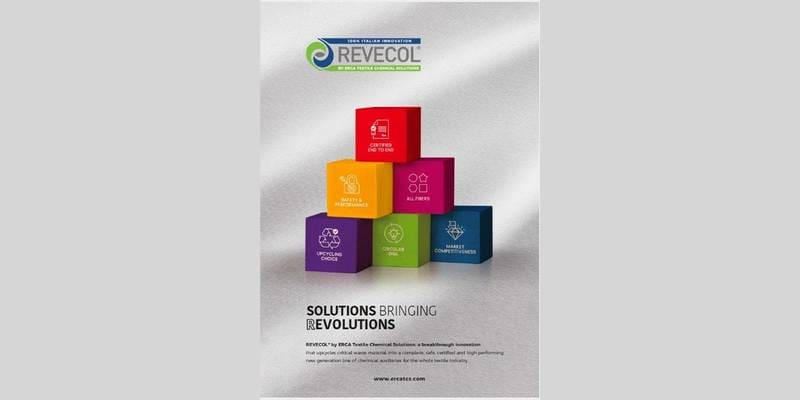

For this reason – and this is the first notable feature – the brand has chosen to present itself through an image that makes immediate not only the idea of responsible innovation in the REVECOL® range of products, but one that also shows its values, representing them as “bricks” which together and in combination constitute the uniqueness of this range.

The new image captures the essence of responsible innovation: each shade in the vibrant colour composition tells a story about the company’s commitment to making a positive impact on the environment and on society. Chemical auxiliaries play a crucial role in different phases of the textile production cycle, but at the same time they represent a complex challenge in terms of reducing environmental impact. The bottom blocks in the image represent specific choices made by ERCA TCS: the use of recycled materials, the vocation for circularity, competitiveness in the market. Attention to safety is built on this foundation, and it is combined with exceptional performance, as well as the ability to use the range of chemical auxiliaries on all textile fibers. Everything is then guaranteed by end-to-end certifications. It is this combination of values and features that brings solutions to the textile market, solutions that mark a real revolution in the name of circularity.

The REVECOL® by ERCA TCS range now includes 18 new generation chemical auxiliaries. For all of them, thanks to its unique and innovative characteristics, REVECOL® has obtained the most important certifications: GRS, RCS, ZDHC Chemical Gateway, bluesign® and GOTS. In particular, with the support and analysis of bluesign® Academy, it is creating, where possible, the Product Carbon Footprint (PCF) for some REVECOL® products, certifying the reduction of CO2 emissions compared to the use of conventional chemistry.

Last, but not least, this great effort in the search for profoundly innovative and increasingly environmentally friendly production processes has earned ERCA the prestigious European Responsible Care® Award 2023, awarded by Cefic-the European Chemical Industry Council, the largest European chemical industry association, founded in 1972. The award recognizes ERCA TCS’ commitment, through the REVECOL® range, to climate neutrality, circularity and the transition towards safe and sustainable chemicals. And it reiterates that the REVECOL® range paves the way for a new generation of chemical auxiliaries capable of transforming critical waste, massively present in the environment, into a range of certified, high-performance, safe and competitive products designed for textiles and suitable for any fiber, with a strong focus on sustainability and carbon neutrality, as confirmed by analyses and certifications.