Fabrics and yarns are produced and processed utilising a variety of methods and materials in the textile industry. Spinning, weaving, knitting, dying, printing, and finishing are some of the subsectors. To create the necessary fabric or textile product, each sector needs particular tools and methods. Fabrics and yarns are created using a variety of natural and synthetic fibres, including cotton, wool, silk, polyester, and nylon. These materials are then transformed into finished goods. The industry’s technologies and methods are always being improved in order to increase productivity, sustainability, and product quality. In accordance with national and international standards, advanced manufacturing procedures are also used to develop environmentally friendly materials and production techniques. By funding research, this ongoing growth promotes a culture of continuous progress. Fabrics and yarns are produced and processed utilising a variety of methods and materials in the textile industry. Spinning, weaving, knitting, dying, printing, and finishing are some of the subsectors. To create the necessary fabric or textile product, each sector needs particular tools and methods. Fabrics and yarns are created using a variety of natural and synthetic fibres, including cotton, wool, silk, polyester, and nylon. These materials are then transformed into finished goods. The industry’s technologies and methods are always being improved in order to increase productivity, sustainability, and product quality. In accordance with national and international standards, advanced manufacturing procedures are also used to develop environmentally friendly materials and production techniques. By funding research, this ongoing growth promotes a culture of continuous progress. Fabrics and yarns are produced and processed utilising a variety of methods and materials in the textile industry. Spinning, weaving, knitting, dying, printing, and finishing are some of the subsectors. To create the necessary fabric or textile product, each sector needs particular tools and methods. Fabrics and yarns are created using a variety of natural and synthetic fibres, including cotton, wool, silk, polyester, and nylon. These materials are then transformed into finished goods. The industry’s technologies and methods are always being improved in order to increase productivity, sustainability, and product quality. In accordance with national and international standards, advanced manufacturing procedures are also used to develop environmentally friendly materials and production techniques. By funding research, this ongoing growth promotes a culture of continuous progress. inverters and their robustness to work in harsh environments (high temperature).

Fabrics & Processing | Fibres and Yarns

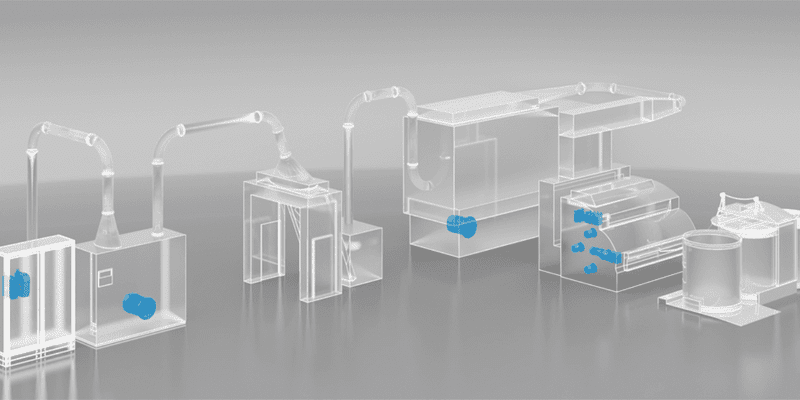

Wide range of solutions for textile processing and machinery from Bonfiglioli

Published: June 8, 2023

Author: DIGITAL MEDIA EXECUTIVE

Related Posts