WeKO and RotaSpray have therefore examined current processing in dyeing and finishing mills to identify opportunities to improve sustainability, productivity, and profitability. “The worldwide textile industry is suffering from COVID-19 impact and the highly unsustainable use of water, energy, and chemicals as well as an immense cost pressure,” says Jayanta Sanyal, Head of Technical Sales & Processes at WEKO.

A new approach to continuous dyeing that uses less water and carbon

One of the primary dyeing methods used today is discontinuous and uses a lot of water, production time, and drainage.

The current continuous dyeing range solutions use a lot of energy, chemicals, and put a lot of strain on the wastewater treatment facilities. The manufacture of tiny batches at a low cost and with minimal waste is also possible in a typical continuous dyeing range. is almost impossible while there is a market for it.

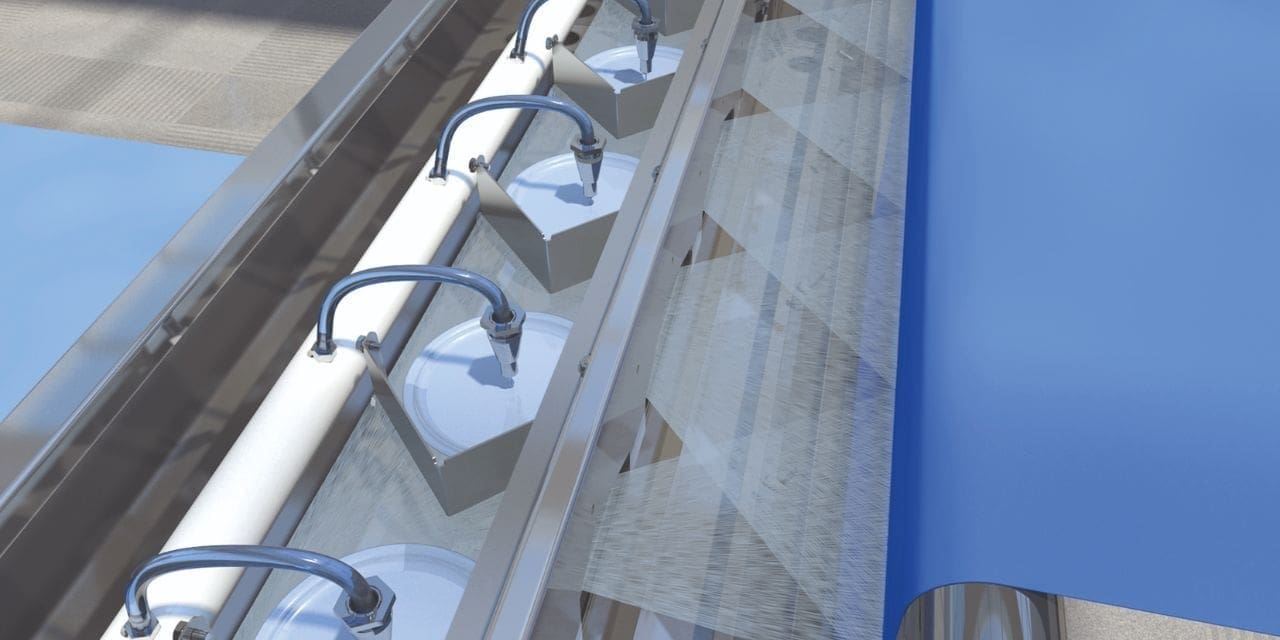

The minimal rotor spray application technology developed by the German firms WEKO and RotaSpray could close this gap.

A novel method of a compact slasher dyeing range for DENIM has just been created and will be promoted during the upcoming ITMA 2023.

A continuous polyester disperse and pigment dyeing process using another newly created technology, WEKO-SPRAY + WEKO DRY-E + WEKO FIX-E, is the most recent advancement made in collaboration with partners.

Carbon-free drying and fixing are possible with WEKO DRY-E and WEKO FIX-E.

Advanced near-infrared (aNIR) light energy, high performance management of the NIR energy, and precisely controlled moisture extraction make up the WEKO DRY-E and WEKO FIX-E technologies.

The system could be applied to various dyeing processes. and finishing lines and combine it with a minimum rotor spray application system to bring forth its full potential. Consider the energy savings that can only be attained by the format setting and immediate start/stop feature. Additionally, water molecules are extracted up to six times faster in several processes like standard stenter frame drying. “This could be a real big step forward in textile processing to strongly reduce the carbon footprint!” adds Jayanta Sanyal from WEKO.